Out of Autoclave

Students develop composite sled prototype

IACMI enables art-to-part composite sled prototype project with University of Tennessee, Knoxville engineering students

Read MoreAirtech's Combo-Tech combines vacuum bagging materials

Airtech Advanced Materials Group (Huntington Beach, CA, US) has introduced Combo-Tech, an expanded product line that bonds various vacuum bagging materials together to form what is said to be a better overall product that reduces touch labor.

WatchVELOX, Ilium Composites now partners

VELOX GmbH a European distributor of raw material specialties for the composites industry, has formed a new distribution partnership with Ilium Composites, a manufacturer of glass reinforcements.

Read MoreMaverick Corp. sister company sold to Loar Group

Maverick Molding, sister company of high-temperature polyimide supplier Maverick Corp., was acquired by New York-based Loar Group.

Read MoreLarge, Class A parts every 60-150 seconds

Romeo RIM advances long fiber injection process efficiency for lighter, lower-cost composite parts.

Read MoreImproving one-piece aerostructures by automating preforming

IAI’s fully automated “one-shot” RTM production line cuts helicopter seat cost 30% vs. hand layup prepreg.

Read MorePlant tour: Diamond Aircraft Austria, Wiener Neustadt, Austria

Composites use among general aviation manufacturers is far from unusual, but none apply them quite like this airframer does.

Read MoreRevolution Composites expands manufacturing facility

Revolution Composites expanded its Norwood, MA manufacturing facility with a 10,000-square-foot addition.

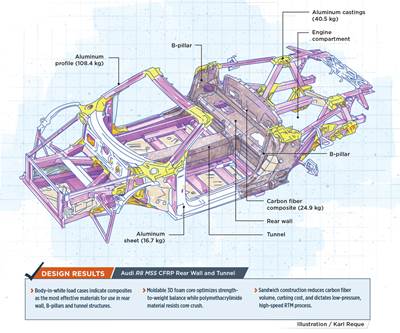

Read MoreAudi R8 seat wall: A prelude to production

Audi takes it upon itself to design and develop carbon fiber composite structures that, the company hopes, will enter high-rate production.

Read MoreVelox to distribute Enka materials in Europe

Composites and plastics materials distributor VELOX GmbH (Hamburg, Germany) has announced the expansion of its distribution partnership with Low & Bonar (London, UK) to distribute Low & Bonar’s trademarked Enka-Channel and Enka-Fusion resin infusion consumables throughout Europe.

Read More