Out of Autoclave

IACMI officially opens new innovation facility in Detroit

Two years in the works, the IACMI Vehicles Scale-Up Facility offers the automotive industry a composite materials and manufacturing development innovation center.

Read MoreAutomated Preforming, Part 5: Holistic Quality Optimization

Simulation and testing key to integrated approach for optimization of automated preforming, offering time and cost savings as well as basis for automated quality inspection.

WatchPorsche and the braided carbon fiber wheel

For just €15,232, you can get a set of four braided carbon fiber wheels on your 2018 Porsche 911 S. This will be the first time a carmaker has offered braided carbon fiber in such an application.

WatchRail line landmark restoration via pultrusion

Composites’ corrosion resistance ensures preservation.

Read MoreRotomolded cores: New options for sandwich composites

Permanent or removable, these hollow thermoplastic cores broaden industry offerings.

Read MoreBiggest hurdles for automotive composites

Patrick Blanchard, global technical leader – composites at Ford Motor Co., discussed at SPE ACCE three major hurdles composite materials face.

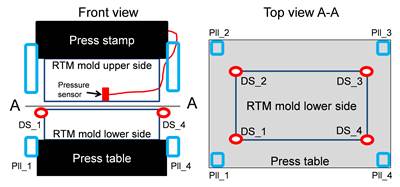

Read MorePressure sensors for high volume RTM molding

A new Work in Progress article examines the use of in-mold pressure sensors to control mold filling in high-pressure resin transfer molding (HP-RTM).

Read MoreFerrari Land features FRP cladding

A total of 800 individual FRP parts were hand layup molded by specialist architectural façades and parts fabricator Look Composites.

Read MoreFraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

Read MoreIBEX 2017 show report

Increased attendance and exhibitors despite Irma, continued delivery of latest in composite technologies for marine industry.

Watch

(1).jpg;maxWidth=400;quality=70)