Given all the attention paid to composites use in the Boeing 787, Airbus A350 XWB and other large, high-profile aircraft, it is easy sometimes to forget that those who build general aviation (GA) aircraft not only embraced composites long before the major airframers, but also continue to do so in ways unheard of in the big planes. Innovation in layup methods, manufacturing processes, out-of-autoclave cure, adhesive bonding and nondestructive testing abound in the GA environment, all developed with the goal of making these craft as efficient, safe and affordable as possible.

Arguably, no GA aircraft manufacturer is more committed to composites use than Diamond Aircraft. For decades, it has pushed the composites envelope to manufacture a line of single- and twin-engine aircraft for a variety of uses, ranging from pilot training to commuting to surveillance. Along the way, the company has developed a creative suite of materials, processes, assembly methods and aircraft architectures that enable it to easily mix and match manufacturing solutions for a variety of aircraft types.

David-Alexander Bausek (Fig. 1), the company’s head of production, says this push-the-limits culture flows down from CEO Christian Dries, whose intentionally high-risk/high-reward environment is designed to drive innovation. “There is a risk that we will fail, but it is very innovative,” Bausek says. “And in most cases, we succeed.”

The heart of Austria

CW’s visit required travel to Austria, about an hour south of Vienna, to the small town of Wiener Neustadt (population 44,000), where Diamond Aircraft spans a multi-building campus adjacent to the single-runway Flugplatz Wiener Neustadt Ost (Wiener Neustadt East Airfield). Founded in 1981 as Hoffmann Flugzeugbau, the fledgling airframer first manufactured the HK36 motorglider. Dries acquired the company in 1991 and, in 1992, bought Diamond Aircraft in London, ON, Canada, then combined the two companies under the name Diamond Aircraft Industries in 1996. Today, the Diamond Canada facility, which focuses on engineering and manufacturing, is 60% owned by Christian Dries. In addition, Diamond Aircraft operates two manufacturing facilities in China via joint ventures, one in Pinau and one in Wuhu.

Diamond Aircraft’s first product was the DV20, a two-seat, single-engine plane, delivered in 1995. A year later, the company rolled out its single-engine DA40 and twin-engine DA42 — planes that eventually put the company on the general aviation map. Today, most of Diamond Aircraft’s manufacturing — as many as 150 aircraft per year, depending on portfolio mix — is split evenly between single-engine and twin-engine aircraft, comprising three models: The single-engine, four-seat DA40; the twin-engine, four-seat DA42; and the twin-engine, seven-seat DA62. Diamond Aircraft also makes the DART 450, a civil single-engine, two-seat aerobatic trainer. And, coming this year is its new single-engine, five-seat DA50-V.

Composites use, as might be expected, has evolved as aircraft have evolved. The early DA40 composites structures are all glass fiber. The later DA42 structures are a combination of glass and carbon fiber, and the more recent DA62 is all carbon fiber. Composites, as a fraction of each plane’s finished weight, are about 30%.

Primacy of platform architecture

Before the tour commences, CW’s guide, Bausek, explains the material and manufacturing philosophy that shapes Diamond Aircraft’s composites fabrication operations. Its overriding principle is that of common platform architecture. For example, the wings of all Diamond Aircraft products are fully interchangeable. Beyond that, the company has a stable of fuselage designs and horizontal flight-surface designs that can be mixed and matched, depending on aircraft type, aircraft size, passenger limit, number of engines and the aircraft’s intended use.

“For instance, the DA40 and the DA42 have the same fuselage, just a different nose section and a different midsection. This gives us the ability to produce more parts out of the same tool,” Bausek points out. He notes that it also limits the mold inventory “and keeps our manufacturing pricing more attractive in terms of cost for the end-user. Also, we have a common part policy. That means we try as much as possible over all aircraft to use common parts.”

In addition, Diamond Aircraft, on the DA40 and DA42 (but not the twin-engine DA62), uses adhesive bonding only to join composite structures. This is done to minimize the need for drilling that might weaken composite structures, and to save the weight associated with metallic fasteners. This means Diamond Aircraft has become highly adept at bondline verification.

Bausek says, “It is not easy to certify a fully bonded aircraft, but we have never had an aircraft structure failure caused by bondline failure.”

Diamond Aircraft also emphasizes simplicity of design, equipment and technology to give the pilot a comfortable and manageable flying experience, combined with easy customization of features and aircraft color. This extends to maintenance as well. All Diamond Aircraft wings, for example, are bolt-on structures, which eases repair and replacement and reduces cost of ownership.

Finally, the company’s operations are very much characterized by its manufacturing systems, which revolve around “wet-preg,” which is the process of applying mixed resin to dry fiber immediately prior to layup. This is called lamination at Diamond Aircraft and it is done for all larger parts automatically, the latter of which is accomplished with in-house developed fiber impregnation machines. Bausek says Diamond Aircraft primarily employs five material/manufacturing combinations, depending on the location and physical and mechanical requirements of the structure:

•Hand lamination without vacuum bag.

•Hand lamination/automated lamination with vacuum bag.

•Automated lamination with vacuum bag in a pressure chamber.

•Automated lamination with vacuum bag and medium heated pressure chamber (autoclave).

•Resin Infusion.

The process limits greatly the shelf life of the wet-preg, Bausek admits, which means that plies must be laid up as soon as they are impregnated, but the quality of the finished structure meets the company’s needs well.

Cutting, kitting

Bausek begins the plant tour in the company’s cutting and kitting area, which features a film-covered floor and film-covered cutting tables. Currently, wet-preg comes into this room following impregnation by hand or automated means and must be hand cut. Bausek says the company is researching automated cutting solutions for its in-house manufactured wet-preg, but the technology readiness level is not high enough yet for serial production.

Smaller parts and structures, including nacelles (Fig. 2), are laid up in the cutting area immediately after they are cut. Ply schedules associated with each mold specify which material to place where and specify periodic quality-control steps to check accuracy.

Bausek notes that Diamond’s common platform concept is operative here. Therefore, one mold can be used to make parts for several different aircraft, but that means the materials, fiber orientation and/or thickness vary by aircraft type. Making sure that a layup meets the requirements of the intended part is critical. “We must make sure the right material is used for the right aircraft,” he sums up.

Carbon fiber is supplied to Diamond Aircraft by Toho Tenax Europe GmbH (Wuppertal, Germany) and Mitsubishi Chemical Carbon Fiber & Composites (Irvine, CA, US). Format is either UD, 2x2 twill or plain weave. A carbon fiber/aluminum weave or a carbon fiber/copper weave is used for the lightning strike protection layer. The epoxy resin for all of Diamond Aircraft’s parts and structures is supplied by Hexion (Columbus, OH, US), including a “legacy” epoxy still used on the DA40 and DA42, and a newer epoxy for the DA62.

Bausek says Diamond Aircraft has enjoyed a long relationship with Hexion, which has been a partner to the company since 1997. Indeed, Hexion technical personnel are frequently at Diamond’s facilities and provide support for all aspects of composites manufacturing.

Large parts

Bausek leads the way into an adjacent room where parts too large for the cutting/kitting room are laid up. Here, a wide variety of molds and other equipment are in several stages of production.

Of particular interest is the lower shell of a DA42 mid-section, which features a spar bridge that connects the wings to the plane’s primary structure. Part of this structure includes the landing gear rib, fabricated from a glass fiber composite, which will better show cracks if it is damaged.

At the next mold, a technician is working on an engine reinforcement structure and has applied adhesive paste to the mating surfaces in advance of bonding.

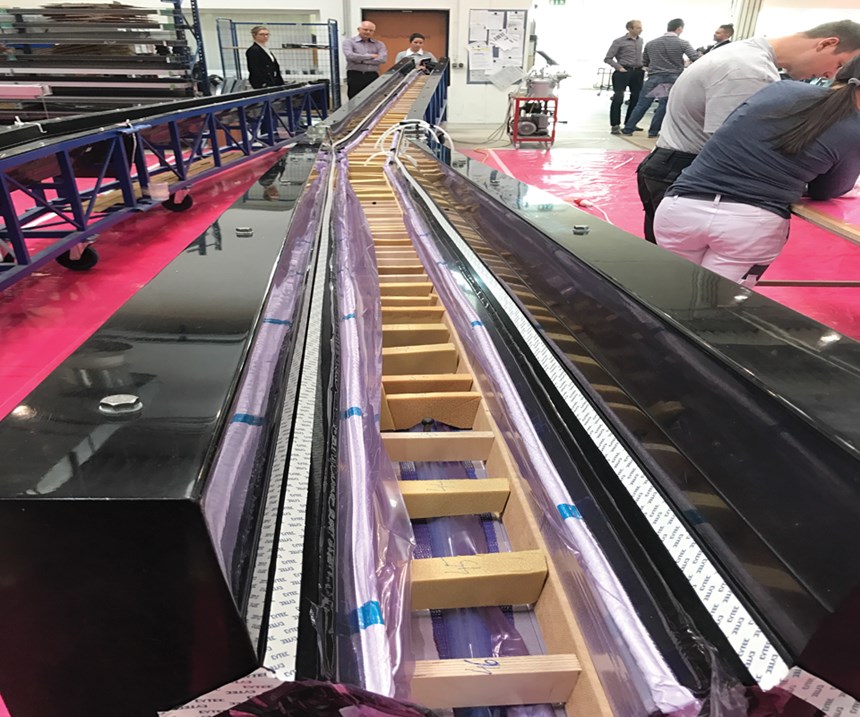

The longest mold in the room is for the main wing C-spar for a DART 450 (Fig. 3). It is one of the few resin-infused parts at Diamond Aircraft. Bagged and under preparation for infusion, its process employs a Membrane Tube Infusion (MTI) resin flow promoter (manufactured by DD | Compound, Ibbenbüren, Germany). Bausek says this C-spar represents the company’s most complex and labor-intensive layup. “The know-how here is the injection point,” Bausek says, “to manage resin flow.”

Moving on, Bausek points out a full DART 450 wing spar structure (two C-spars) in a bonding fixture (Fig. 4). The spar is part of a “wet” wing, meaning that aircraft fuel will be stored inside the wing structure, in addition to other onboard fuel tanks.

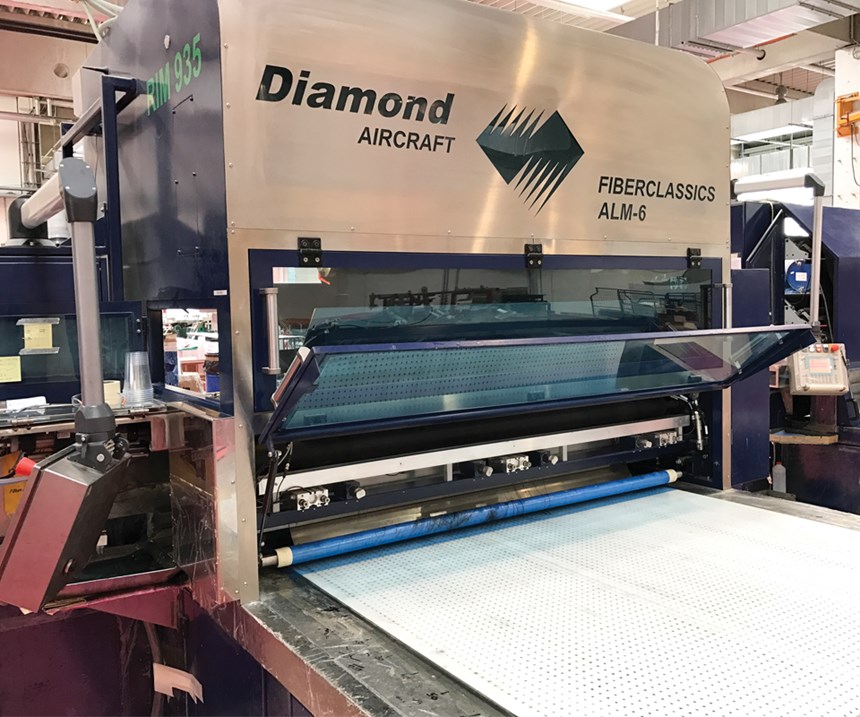

Following this, CW watches as one of Diamond’s in-house-built Automated Laminating Machines (ALM, Fig. 5, top left) applies Hexion liquid epoxy to 60-inch-/1.52m-wide carbon fiber laminates, which are then cut and immediately applied by a team of technicians that is working on — and in — a large DA62 half-fuselage mold. When the technicians are done with layup, the mold will be bagged for pre-cure in a heating room at temperatures around 45°C. Bausek says it takes about 6 hours to lay up one half of a DA62 fuselage.

As noted, the manufacturing process Diamond Aircraft employs depends on the part’s structural requirements. With vacuum bagging of the laminate material, says Bausek, parts porosity is about 2.4%. More void-free molding processes are used for spars, spar caps and radomes. “Everywhere that we need very low porosity and high quality,” Bausek explains, infusion or medium-heated pressure chambers are used, which provides 0.2% porosity or less.

After cure, structures are adhesively bonded together. The only bonding paste Diamond Aircraft uses is a modified form of Hexion’s legacy epoxy resin. Bausek says this is applied primarily by hand and only occasionally via automated methods. The company, he says, would like to move toward more automated paste application, but that would require a material that has more consistent viscosity characteristics, which is something Hexion is working on. All mating surfaces of all structures, Bausek says, must be easily accessible for external interrogation and assessment, which is performed with a BondMaster ultrasonic bond tester, manufactured by Olympus (Waltham, MA, US). Diamond Aircraft also uses traditional tap testing, which the company says works very well. It also considers tap testing not unlike ultrasonic testing: “Same principle, different frequency,” quips Bausek.

The next stop is CNC machining, which is performed with an HG Grimme SysTech GmbH (Wiedergeltingen, Germany) rotary cutter (Fig. 6). Offering 5 axes of freedom at the spindle, with another two available via part manipulation, the system cuts holes for fuel ports, instruments and other devices. At this point, also, the interiors of the wings are fitted with rubber liners for fuel contact.

Pre-assembly, paint, assembly

Bausek moves on to pre-assembly (Fig. 7), where wings, doors, tails and fuselages come together for final fitting, after which they are sent to post-cure at 120°C for 6 hours. Next comes painting, which is done in one of three paint booths. This includes epoxy primer/filler, grinding, electrostatic discharge coat and then final color coat.

After painting, all composite structures move on to final assembly (Fig. 8), where the plane’s noncomposite components — windows, seats, avionics, wing guts, ailerons, flaps, push/pull rods, fuel tanks, engines, propellers (wood core with glass fiber skin), landing gear and de-icing systems — are integrated to realize the final aircraft. Bespoke features ordered by customers are usually added here as well. DA40s and DA42s are assembled on one side of the assembly area, with DA62s assembled on the other. Each craft, when it is fully assembled, goes through five hours of production flight testing before customer delivery.

A finished DA40 weighs 900 kg, is 8m long, 2m high and has a wingspan of 11.6m. The DA42 weighs 1,410 kg, is 8.6m long, 2.5m high and has a wingspan of 13.55m. The DA62 weighs 1,590 kg, is 9.2m long, 2.8m high and has a wingspan of 14.5m. The single-engine, five-seat DA50, when it enters the market this year, will weigh around 1,200 kg, be 9m long, 2.9m high and have a wingspan of 13.4m.

Increasingly, manufacture and assembly of Diamond Aircraft planes will migrate out of Austria and toward the company’s other facilities. Indeed, DA62 production was moved to Diamond Canada in October 2017. As this pattern continues, the Wiener Neustadt facility will focus more on research and development and low-rate production, and less on full-rate production.

Says Bausek: “Diamond Aircraft Industries, with its innovative spirit, has progressively innovated sustainable, environmentally friendly, reliable, high-performance general aviation products, and will continue to help make general aviation the automobile of future.”

The final stop of CW’s Diamond Aircraft tour was a walk out of the final assembly line and onto the tarmac, where a DA40 and a test pilot waited to give us a demonstration flight (Fig. 9). The captivating 45-minute flight took us up to, and around, the snow-capped peaks of the Alps surrounding Wiener Neustadt. And then safely back to Earth.

Related Content

SGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreCSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreCCG meets customer demand with StormStrong utility pole lineup

Additional diameters build on the portfolio of resilient FRP pole structures for distribution and light pole customers.

Read MoreCCG FRP panels rehabilitate historic Northamption Street Bridge

High-strength, composite molded, prefabricated panels solve weight problems for the heavily-trafficked bridge, providing cantilever sidewalks for wider shared use paths.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More