Processes

Tooling: 3D printing’s “killer app”

If 3D printing can be scaled to make tools for composite auto body panels ... it will be transformative

Read MoreAutomated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

WatchAirtech's Combo-Tech combines vacuum bagging materials

Airtech Advanced Materials Group (Huntington Beach, CA, US) has introduced Combo-Tech, an expanded product line that bonds various vacuum bagging materials together to form what is said to be a better overall product that reduces touch labor.

WatchVELOX, Ilium Composites now partners

VELOX GmbH a European distributor of raw material specialties for the composites industry, has formed a new distribution partnership with Ilium Composites, a manufacturer of glass reinforcements.

Read MoreMikrosam expands into North America

Macedonia-based Mikrosam will partner with New Jersey-based Composites Automation LLC to sell its composites automation system into North America.

Read MoreSymmetrix Composite Tooling opens second innovation center in Nevada

The Nevada location will initially handle projects for existing customers and will begin accepting projects for new clients in the spring of 2018.

Read MoreLarge, Class A parts every 60-150 seconds

Romeo RIM advances long fiber injection process efficiency for lighter, lower-cost composite parts.

Read MoreReal-time automated ply inspection (RTAPI) system: CW’s series on automated inspection methods

More composites being used in aircraft, and the pressure for higher production rates means new technologies for automated, in-process inspection while the part is being fabricated. Groups around the world are working on this, and making great strides.

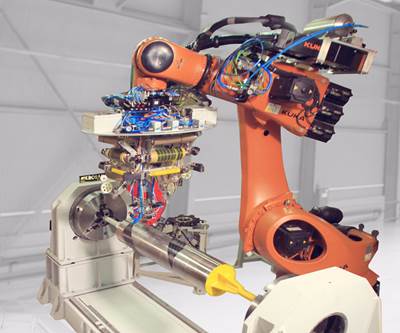

WatchImproving one-piece aerostructures by automating preforming

IAI’s fully automated “one-shot” RTM production line cuts helicopter seat cost 30% vs. hand layup prepreg.

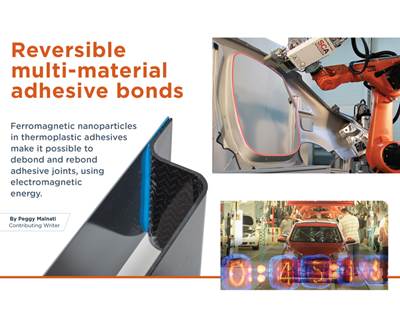

Read MoreReversible multi-material adhesive bonds

Ferromagnetic nanoparticles in thermoplastic adhesives make it possible to debond and rebond adhesive joints, using electromagnetic energy.

Read More

.jpg;maxWidth=300;quality=90)