Processes

Plant tour: Diamond Aircraft Austria, Wiener Neustadt, Austria

Composites use among general aviation manufacturers is far from unusual, but none apply them quite like this airframer does.

Read MoreRevolution Composites expands manufacturing facility

Revolution Composites expanded its Norwood, MA manufacturing facility with a 10,000-square-foot addition.

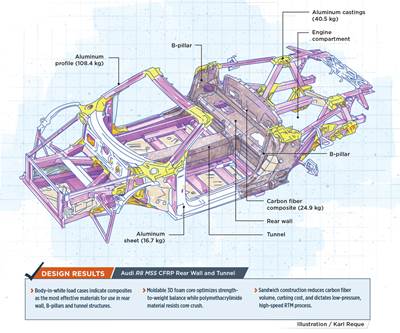

Read MoreAudi R8 seat wall: A prelude to production

Audi takes it upon itself to design and develop carbon fiber composite structures that, the company hopes, will enter high-rate production.

Read MoreVelox to distribute Enka materials in Europe

Composites and plastics materials distributor VELOX GmbH (Hamburg, Germany) has announced the expansion of its distribution partnership with Low & Bonar (London, UK) to distribute Low & Bonar’s trademarked Enka-Channel and Enka-Fusion resin infusion consumables throughout Europe.

Read MoreCTG Bel-Kur adds 5-axis vertical machining center

The new machine expands the company’s machining department, and helps to improve productivity when producing multi-sided and complex parts.

Read MoreSGL offers high-performance organosheet and thermoplastics for overmolding

“Thermoplastic toolbox” includes LFT, UD tapes, woven semi-finished sheets and carbon/glass hybrids in PA and polyolefins for automotive and other high-volume applications.

Read MoreCW Talks: How carbon fiber beat out steel in elevator cabling

CW Talks: The Composites Podcast learns from KONE’s Steve Gonzalez how pultruded carbon fiber UltraRope was developed to help move elevators up and down in the world’s tallest buildings.

Read MoreCFRP bests steel in precision ball joints

Near-zero backlash in bearings and automation components.

Read MoreDelta Airlines installs LEWCO composite curing oven

The curing oven will be used to manufacture parts for Delta’s airplane cabins.

Read MoreAirborne introduces automated kitting solutions

At AIRTEC 2017, the aerospace supply chain trade show held October 24-26 in Munich, Germany, composites specialist Airborne (The Hague, Netherlands) presented the latest developments on its Automated Kitting Solutions.

Read More