Processes

Additive manufacturing and composites: An update

Additive manufacturing has only begun to tap the potential available in the composite industry.

Read More3D TPC structural preforming process lightens car doors

Automated cell manufactures and pre-impregnates continuous-fiber 3D preforms for injection/compression overmolding of parts with complex shapes, and tailored structural properties.

Read MorePreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

WatchComposites recycling: Gaining traction

Recycling of carbon fiber, glass fiber and — at last — resins, is growing as new players enter the space.

Read MoreEuropean SAMPE meeting explores composites innovation

High spots from SAMPE Europe’s Summit 17.

Read MoreProcess automation: A model response to Trumponomics and Brexit?

Offshoring can’t go on forever and a significant trend toward reshoring is probably inevitable.

Read MoreCompositesWorld's story planning journey

Automotive materials and process innovation in the driver’s seat.

Read MorePeople on the move: April 2017

Here is this month’s people on the move news in the composites industry.

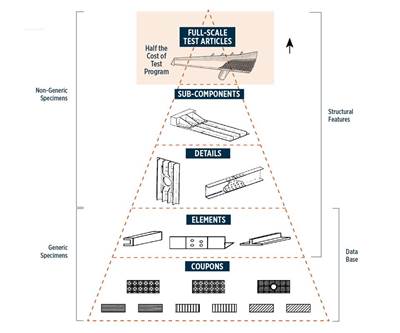

Read MoreAccelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

Read More