Processes

Addcomposites highlights novel composites manufacturing developments

AFP-XS and AddPath updates, new AFP and continuous AM systems, upcoming webinars and blog content are available to interested industry members.

Read MoreUrban furniture project demonstrates green potential for composite 3D printing and recycled materials

Large-format AM specialist Caracol and partners designed custom, 3D-printed outdoor furniture with glass fiber-reinforced recycled polypropylene, and conducted an LCA to evaluate and improve the process.

Read MoreVIDEO: Sustainable pressure vessel systems for heavy-duty vehicles

Automotive and filament winding experts at Voith Composites showcased their Type IV hydrogen storage tanks at JEC 2023. These 350-liter pressure vessels, manufactured with recycled carbon fiber, are primarily designed for heavy-duty vehicles.

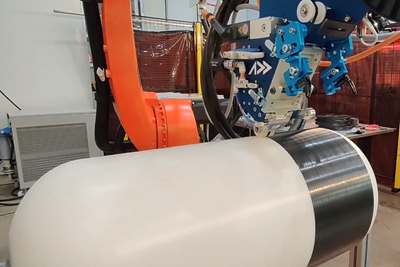

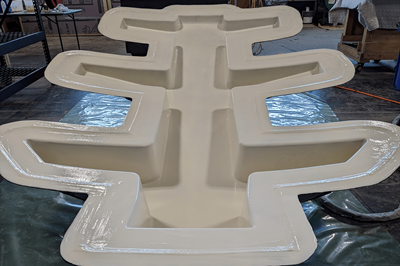

WatchAFPT combines tape winding, placement into one tool

Typically separate processes, the company’s new vessel winding head (VWH), merged with a multiple tape laying head (MTLH) progresses composite pressure vessel development.

Read MoreElastomer reusable vacuum bags address traditional material limitations

CAMX 2023: Sprayomer Technology Amor-Vac RVBs, distributed by Technology Marketing, are said to be more efficient, sustainable, long-living and lighter in weight compared to sprayable silicone or nylon film alternatives.

Read MoreZCC Zünd Cut Center ushers in enhanced digital cutting automation

ZCC V.4 supports operators with several new smart, intuitive digital cutting functions throughout the composite material handling workflow.

Read MoreServo-based pultrusion machines for composite profile production

CAMX 2023: Kent Pultrusion is displaying its turnkey ServoPul servo-driven pultrusion lines and secondary equipment for handling composite profiles.

Read MoreIntelligent autoclaves emphasize sustainability, efficiency

CAMX 2023: Olmar introduces its “intelligent” autoclave, a combination of the company’s Industry 4.0 technology and its 75 years experience in autoclave and oven manufacture.

Read MoreThermal processing workflow software effectively monitors composite processing equipment

CAMX 2023: State-of-the-art, user-friendly PCS 2.0 showcased by Walton Process Technologies is an Industry 4.0 process control software for autoclaves, presses and ovens.

Read MoreThermally conductive mandrels enhance filament winding capabilities

CAMX 2023: Acrolab features its Isomandrel technology, which redistributes high thermal energy uniformly over the entire filament winding mandrel surface, providing predictable and consistent energy input into the part and removing the need for oven cure.

Read More