Reinforcements

Designing and manufacturing turbine test nacelles

Michigan-based Ground Test Solutions (GTS) shares the design and manufacturing processes involved in building composite nacelle components used in testing jet and helicopter engines.

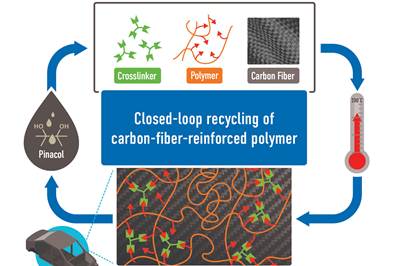

Read MoreORNL develops dynamically crosslinked CFRP, enabling closed-loop recycling

At laboratory scale, functionalized CFRP thermosets can be “released” via heat or chemicals to reincarnate them back into their starting materials.

Read MoreEve selects composite seats from Recaro Aircraft for 2026 eVTOL

The delivery, to include 75,000 GFRP seats, marks Recaro’s entry into the AAM market.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

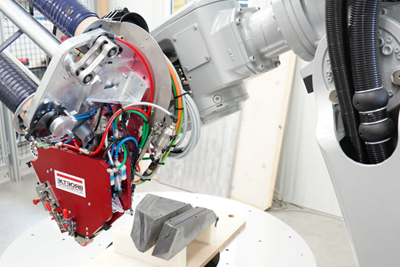

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreHyfer Objects furniture incorporates Sulapac wood composites

High-end design furniture is 3D printed from bio-based, eco-friendly materials for aesthetic and sustainable home product options.

Read MoreToray celebrates commissioning of expanded Torayca T1100 production line

Doubled carbon fiber production capacity at Toray’s Decatur, Alabama, plant will support rising demand in U.S. defense.

Read MoreCRP Technology launches Windform SL for UAV needs

Carbon fiber-reinforced polyamide, added to CRP’s Top-Line series, is well suited to demands for lightness, stiffness and thermal resistance in composites 3D printing.

Read MoreReCarbon becomes commercialization partner for Fibertech Group

ReCarbon will focus on providing a high-quality recycled carbon fiber-based product range, using Fibertech’s prepreg expertise.

Read MoreEnvalior, Koki deliver lightweight, efficient automotive shift fork design

Use of Envalior’s fiberglass-reinforced ForTii ACE MX53 and collaboration with its CAE department helped Koki re-adjust product design, simulation and tooling to get the best out of material performance.

Read More