Resins

SPE ACCE 2015 show report

Was this the year, finally, for the big break-through for automotive composites? Maybe, depending on to whom one talked or the presentation one heard.

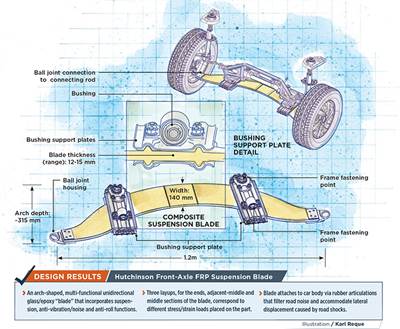

Read MoreAutomotive front axle: A glass act

The development of glass-fiber reinforced car axle is a sign of the new, expanded role composites will play in the design of future automobiles.

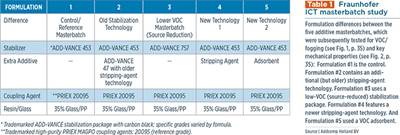

Read MoreVOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

Read MoreAeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreAutomotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

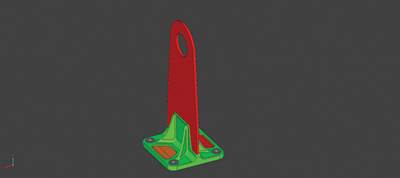

Read MoreComposite brackets for life-of-aircraft service

Reinforced PEEK molding formulated for jet fuel/hydraulic fluid immersion.

Read MoreOuter space: The “final frontier” is exciting again!

CW contributor Dale Brosius, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI), points to evidence that the composites industry will, once again, be the beneficiary of renewed drive for space exploration.

Read MoreComposites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

Read MoreResins for the Fast Zone

An automotive supplier must have the ability to produce a composite part in a minute, or at least in minutes — not hours or days, the norm for composites in most other industries. Meeting that part-per-minutes goal is a huge hurdle that a few composite fabricators have cleared, and many more are involved in development efforts, with OEM or Tier partners. CompositesWorld reviews how resin suppliers have evolved their products for this critical market.

Read MoreOvermolding expands PEEK’s range in composites

A new polymer and a hybrid process enable production of complex, high-load-capable, fiber-reinforced brackets and clips in minutes.

Read More