Resins

Autocomposites Update: Engine oil pans

As thermoplastic composites makes inroads into these complex, modular parts, weight and cost go down, functionality goes up.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreDonauwörth as composites pioneer

Airbus Helicopter Germany produces composite primary structure for 30+ years, first all-composite doors for A350 XWB and latest “kinked” composite blades for new “quiet” rotorcraft.

WatchNew hydraulic press for automated processing of thermoplastic CFRP

Wickert Presstech delivers new system to German Aerospace Center which reportedly can process all materials and uses latest in automated technology.

Read MoreDuraStor/HOST participants

In 2010, a multi-partner, multi-year research program called Low Cost, Durable Thermoplastic Hydrogen Storage Tanks, or DuraStor, was formed to address these problems by investigating a drop-in replacement for Type IV tanks. A UK-only program called Hydrogen – Optimisation of Storage and Transfer (HOST) picked up where DuraStor left off in mid-2014. These were the participants.

Read MoreNew aerocomposites niche: Helicopter transmission gears?

A NASA study shows that steel/composite hybrid gears save significant weight, and could mitigate vibration-related noise.

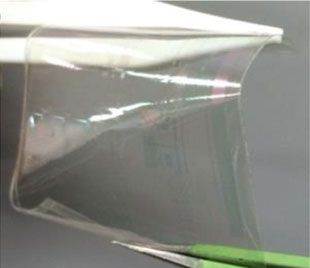

Read MoreFully transparent, rollable electronics built with graphene/CNT backbone

Carbon nanotubes and graphene provide mechanical properties and bonding enabling high-temp polyimide resin to provide flexible circuit substrate.

Read MoreComposite tooling without oven or autoclave

No Oven No Autoclave technology has been demonstrated in tooling for NASA, including multiple thermal cycles and use for curing epoxy infused out-of-autoclave parts.

Read MoreThe matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

Read More