RTM

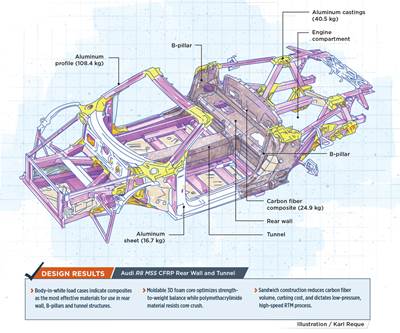

Audi R8 seat wall: A prelude to production

Audi takes it upon itself to design and develop carbon fiber composite structures that, the company hopes, will enter high-rate production.

Read MoreCFRP bests steel in precision ball joints

Near-zero backlash in bearings and automation components.

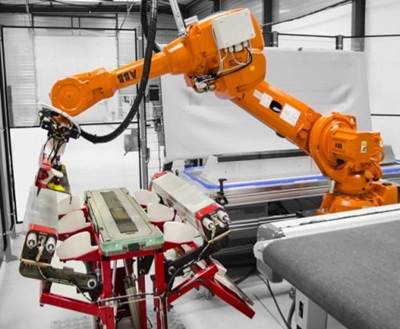

Read MoreAutomated preforming: Intelligent automation in pick-and-place systems

Layups go industrial with hand-like grippers that can fold fabric or prepreg into corners and robot-mounted cameras that inspect from fabric to cut plies to fiber gaps in final preforms.

Read MoreIACMI officially opens new innovation facility in Detroit

Two years in the works, the IACMI Vehicles Scale-Up Facility offers the automotive industry a composite materials and manufacturing development innovation center.

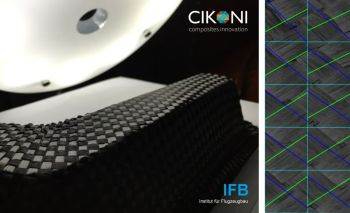

Read MoreAutomated Preforming, Part 5: Holistic Quality Optimization

Simulation and testing key to integrated approach for optimization of automated preforming, offering time and cost savings as well as basis for automated quality inspection.

WatchRotomolded cores: New options for sandwich composites

Permanent or removable, these hollow thermoplastic cores broaden industry offerings.

Read MoreBiggest hurdles for automotive composites

Patrick Blanchard, global technical leader – composites at Ford Motor Co., discussed at SPE ACCE three major hurdles composite materials face.

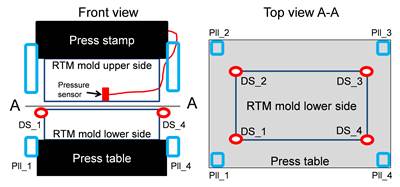

Read MorePressure sensors for high volume RTM molding

A new Work in Progress article examines the use of in-mold pressure sensors to control mold filling in high-pressure resin transfer molding (HP-RTM).

Read MoreFraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

Read MoreReconfigurable tooling: Revolutionizing composites manufacturing

Shape-changing molds eliminate tooling for large 3D panels while automated assembly fixtures go modular, using metrology to reduce cost and shimming.

Read More