Work In Progress

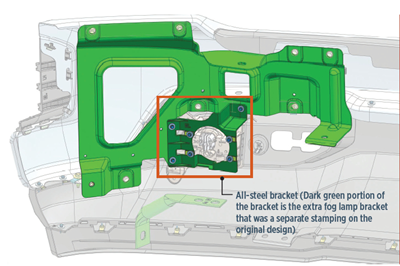

Thermoplastic composites: Structural bumper bracket

Hybrid bracket reduces mass, increases design flexibility, package space in pickup front bumper.

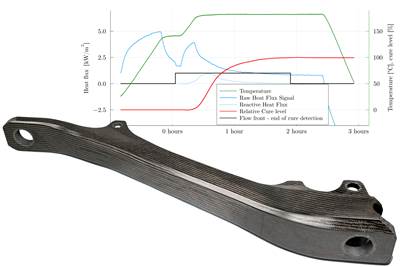

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

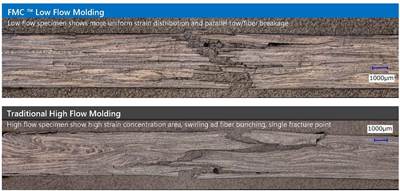

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

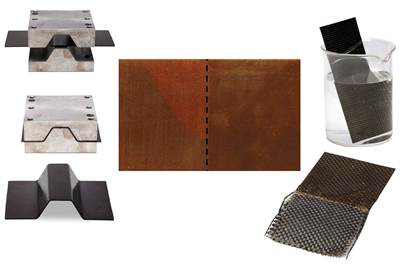

Read MoreReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

WatchIncreasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

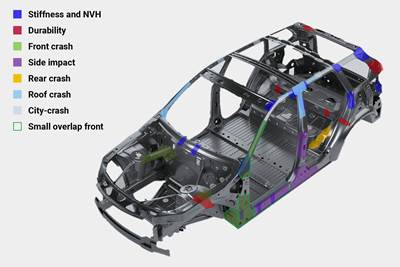

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

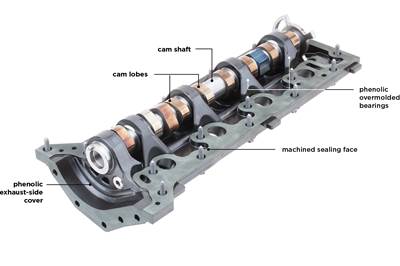

Read MoreGlass fiber and phenolic prove their mettle in camshaft module

Replacing aluminum, a fiberglass/phenolic module reduces mass and NVH in a prototype structure and speeds assembly line installation.

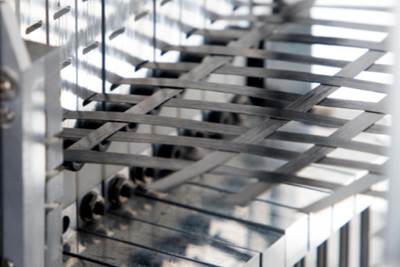

Read MoreAutomated weaving system targets high-performance, high-volume applications

Startup WEAV3D Inc.’s technology produces highly tunable, woven lattice reinforcements for cost-effective, high-volume automotive composites and precast concrete applications.

WatchTow steering, Part 3: The birth of tow shearing

In-plane shearing of tows, versus in-plane bending of tows, hopes to take automated fiber placement directionality to new levels.

Read More