Work In Progress

Composite tension leaf springs: Available for trucks at last

Tension leaf springs with progressive spring rates meet the demanding needs of truck suspensions.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreInside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

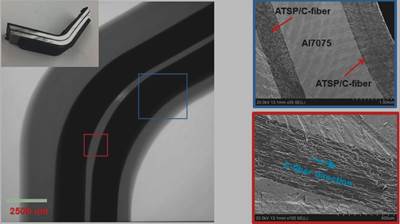

WatchNew polymer expands composites options in demanding environments

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

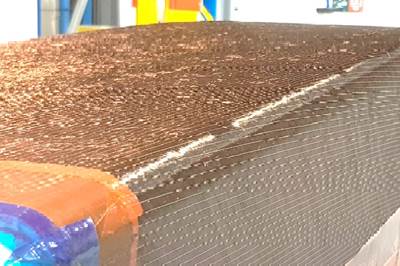

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreEvolution of the one-piece, all-composite Funny Car body

Large, one-piece drag racing vehicle bodies require extreme lightweighting and precise layup skills. Specialist MTCcorp shares how its John Force Racing Funny Cars have evolved over the past 25 years.

Read MoreFlexible, induction-based heating for thermoplastic composite part repair

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

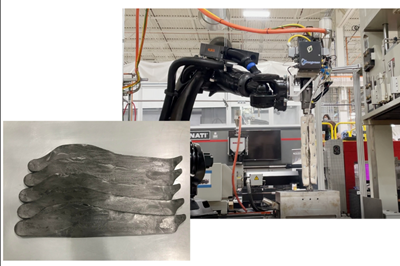

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

Watch