Work In Progress

Composites fill the gaps in museum dinosaur skeletons

Ontario-based Research Casting International uses composites to build lightweight, durable dinosaur castings for museums around the world.

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreNarrow UD tapes to bridge the ATL-AFP gap

Automated tape laying and automated fiber placement are similar, but not the same. Can narrow tapes provide a middle ground with advantages of both processes for next-gen aircraft?

WatchComposites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

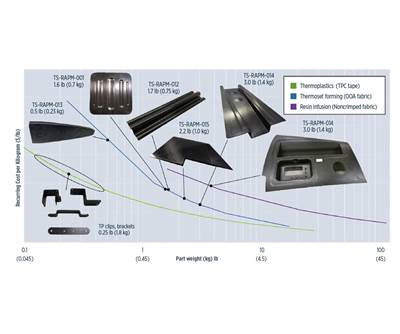

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreCurved pultrusions enter production

Corvette CFRP rear bumper beam is the auto industry’s first use of new technology.

Read MoreThe evolution of composites in NASCAR

The growing role of carbon fiber in stock car racing.

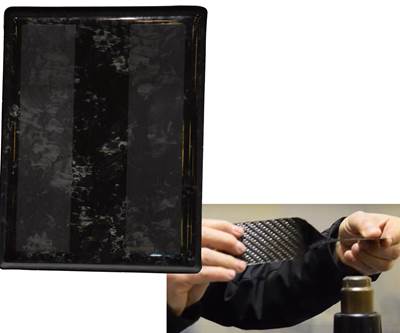

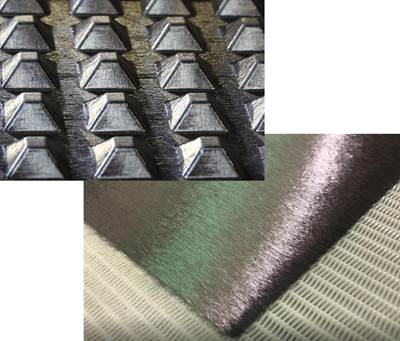

Read MoreRevolutionizing the composites cost paradigm, Part 1: Feedstock

Highly-aligned, short-fiber Tailorable Universal Feedstock for Forming achieves aerospace properties, metal-like formability in zero-waste, fiber-to-parts pilot plant.

WatchGreener camping: Sonic X breaks barriers

Prototype travel trailer generates excitement, leads to new commercial models.

Read MoreAutomation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

Read More