3R epoxy resins, more sustainable composites

CIDETEC’s patented epoxy vitrimer resins provide cure cycles and properties comparable to conventional aerospace epoxies but also allow a range of behaviors more akin to thermoplastics: reprocessing via thermoforming (left), joining via welding, repair of delaminations using heat and pressure (center) and recycling by solvolysis (right) as well as by remolding ground up scraps. Photo credit for all images: CIDETEC

For most aerospace composite structures, thermoset epoxy has been the preferred matrix resin due to its high mechanical properties, low cure shrinkage and resistance to temperature and moisture, which prevents environmental degradation during service. These advantages result from epoxy’s cross-linked molecular structure formed during cure. However, this thermosetting covalent chemistry has also meant that traditional cured epoxy composites cannot be readily remolded, reshaped or dissolved, which makes recycling and repair more challenging.

Over the last decade, dynamic chemistries have been developed in which covalent bonds are exchanged and rearranged with a stimulus such as heat. Referred to as “reversible resins,” these polymers have thermoset properties below the glass transition temperature (Tg), yet behave like a thermoplastic at elevated temperatures, such as 80°C above Tg. CIDETEC (Donostia-San Sebastian, Spain) is an applied research organization that has been working on such resins since 2013. It has patented thermo-mechanically reprocessable epoxy resins and composites based on the exchange of aromatic disulfides, which enables reprocessing, repair and recycling (3R technology) of cured composites. CIDETEC now leads 11 partners in the Horizon2020 project AIRPOXY to mature this technology from technology readiness level (TRL) 3 to TRL 5.

Started in September 2018, this 42-month project will advance 3R composite thermoforming processes for high-volume production, cost-effective 3R composite repair and assembly via thermoset welding and improved adhesive bonding. These technologies will be showcased in two aerospace demonstrators: a composite fan cowl section with resin transfer molded (RTM) skin and transverse stiffener adhesively bonded to a thermoformed longitudinal stiffener; and a section of a wing leading edge with thermoformed ribs welded to a skin made using same qualified RTM (SQRTM). CIDETEC is also exploring recycling of 3R composite materials and parts and evaluating the advantages of this technology versus traditional composites using life cycle assessment (LCA) and life cycle cost (LCC) methodologies.

3R epoxy vitrimer

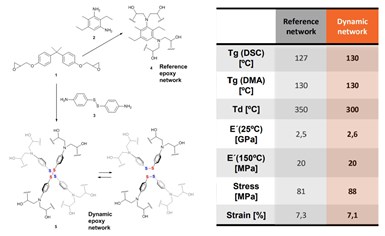

Fig. 1. Dynamic epoxy resin

CIDETEC 3R epoxy achieves comparable thermal and mechanical properties using its dynamic hardener compared to the reference epoxy using a conventional hardener.

“Dynamic chemistry can be classified into two types: dissociative and associative,” explains Alaitz Rekondo, head of Polymers and Composites at CIDETEC. She notes that with dissociative chemistry, the crosslinks are broken. “The materials will thus lose integrity with thermoforming and recycling due to the broken bonds.” CW has written about this type of chemistry via Evonik’s (Essen, Germany) thermoreversible crosslinked resin based on Diels-Alder reactions and Connora’s epoxy hardener Recyclamine, which enables cleavage of crosslinks. This is achieved by immersing Recyclamine composites in a low-pH solvent at elevated temperature, converting the resin to a thermoplastic epoxy while freeing the continuous fiber reinforcement so that both resin and fiber can be reused. Note, Recyclamine was acquired in 2019 by Aditya Birla Chemicals (Mumbai, India) and is now used in Epotec recyclable epoxy resins.

However, CIDETEC’s 3R resins are different. “Our chemistry is associative, so the crosslinks are never broken,” notes Rekondo. “Our resins are vitrimers.” CW introduced vitrimers in Jeff Sloan’s 2020 article on Mallinda (Denver, Colo., U.S.). “So, the resins behave like a thermoplastic during all of the processing,” she explains, “due to the dynamic exchange during heating — for us this happens in aromatic disulfide bonds — but the resins always remain thermosets. Unlike many vitrimers, 3R resins do not require catalysts. But we can use catalysts, if necessary, to meet different requirements for fast-cure/snap-cure cycles or curing at room temperature.”

CIDETEC began its vitrimers research with soft elastomeric materials looking for self-healing properties. “We were using a commercially available dynamic hardener and then realized it is also a hardener for epoxies,” says Rekondo. Initial, industrial-grade 3R epoxy resin formulations showed properties comparable to current aerospace epoxies (Fig. 1). “Seeing the great potential for reprocessable and recyclable resins for aerospace, this is now one of our main areas of research.”

Nerea Markaide, the AIRPOXY project coordinator at CIDETEC, explains that the potential is indeed great: 3R thermoforming enables high-volume composites production that is significantly faster and cheaper versus an autoclave, 3R repair is 50% cheaper than current bonded composite patch methods, 3R welding reduces assembly cost by 55% compared to current adhesive bonding and 3R adhesive bonding is more robust than current methods. Ultimately, CIDETEC envisions a family of 3R resins and adhesives to improve the cost and sustainability of composite aerostructures production.

Prepregging, RTM and thermoforming

CIDETEC, in charge of the formulation of the aerospace-grade 3R resin, identified the best resin formulation for demonstration trials. This system for resin infusion or RTM has a Tg of 170°C dry/150°C wet, a viscosity of 200 centipoise at 70°C and low moisture absorption (2-3%). It can be formulated as a one- or two-component system with a typical cure of one hour at 130°C and post cure of 30 minutes at 180°C.

CIDETEC used this 3R resin formulation to impregnate Chomarat (Le Cheylard, France) five-harness satin (5HS) fabric made with intermediate modulus carbon fiber in a continuous prepreg process. This prepreg was then used by the Leibniz-Institut für Verbundwerkstoffe (IVW, Kaiserslautern, Germany) to manufacture multi-layer flat and 3D-shaped 3R laminates by continuous compression molding (CCM).

3R laminates were also made using RTM to infuse 5HS and unidirectional (UD) fabrics using process parameters optimized for the 3R resin by Eurecat (Barcelona, Spain). Ingeniería y Desarrollos en Composites (IDEC, Araba, Spain) will demonstrate RTM production in an industrial environment using the same resin while it begins trials to produce the RTM skin and transverse stiffener for the 0.5-meter x 0.5-meter fan cowl subcomponent demonstrator.

Meanwhile, Coexpair (Namen, Belgium) and Sonaca (Charleroi, Belgium) will combine Hexcel (Stamford, Conn., U.S.) HexPly 8552 toughened epoxy prepreg with 3R resin film — which will enable welding (see below) — to produce the curved nose structure for the 1-meter-long leading edge subcomponent demonstrator using the same qualified RTM (SQRTM) process (see “SQRTM enables net-shaped parts”).

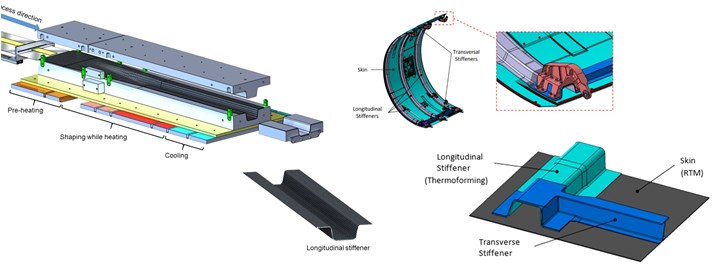

Fig. 2. Fan cowl subcomponent demonstrator

IDEC will oversee bonding of 3R laminate stiffeners and skin using 3R adhesive film. IDEC will make the skin and transverse stiffener using RTM while EireComposites will make the longitudinal stiffener using CCM. Photo credit: IVW (left and lower right) and IDEC (upper right)

Both prepreg and RTM flat 3R laminates have also been used to demonstrate thermoforming. Simulations used were based on micro- and macroscopic finite element models (FEMs) developed by Altair Engineering (Antony, France), IVW-optimized discontinuous compression molding (DCM or stamping) and CCM processes for 3R materials. EireComposites (County Galway, Ireland) is using DCM to produce the ribs and longitudinal stiffeners for the demonstrators while IVW is producing longitudinal stiffeners using CCM. Both processes use around 20 bar of pressure while heating to roughly 210°C, followed by cooling of the part in the closed mold (Fig. 2). Testing led by Eurecat showed that thermoformed 3R composite parts meet typical aerocomposites requirements, including <2% void content. It also found that interlaminar shear strength (ILSS) for the thermoformed laminates with 5HS was roughly 80% (43 MPa) of that for the RTM parts (54 MPa).

Bonding, welding, SHM and repair

CIDETEC’s 3R resin has also been formulated for adhesive films, shown here during manufacture in February 2020.

CIDETEC reformulated the 3R resin to optimize it for adhesive bonding and produced the first 3R adhesive films in February 2020. “The use of dynamic resin both in the substrates and in the adhesive,” explains Rekondo, “achieves chemical bonding in the joint thanks to the disulfide bond reshuffling, which improves the integrity of the joint.” IDEC will oversee the bonding of stiffeners and skin using 3R adhesive film to produce the fan cowl subcomponent demonstrator (Fig. 2).

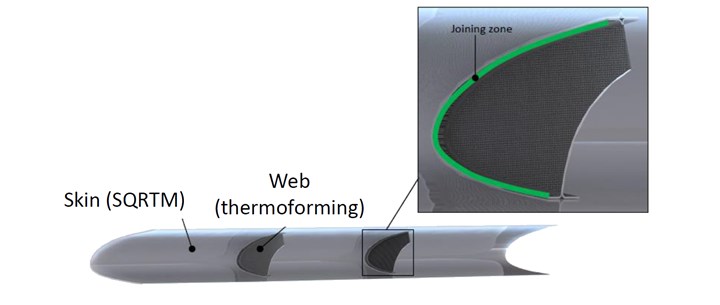

The dynamic chemistry of 3R resins also allows creation of covalent bonds between two 3R composite laminates when joined using heat and pressure — described by CIDETEC as thermoset welding. This will be used by EireComposites to join stamped 3R laminate ribs to the SQRTM nose for the wing leading edge demonstrator (Fig. 3). Optimized welding parameters have been developed by IVW for the 3R laminates. Notably, the SQRTM nose produced with the commercial prepreg integrates an additional 3R resin film at the surface to allow for welding of the two webs. “The process to carry out the welding at a demonstrator level is being studied now,” notes Rekondo.

Fig. 3. Leading edge subcomponent demonstrator

EireComposites will weld together two ribs it thermoforms from 3R laminate using discontinuous compression molding (DCM or stamping) to a 1-meter-long 3R laminate skin designed and manufactured by Sonaca using SQRTM. Photo credit: Sonaca ©2020

In work package 4 – structural health monitoring (SHM) and repair, IVW investigated the reparability of defects, such as delaminations and detached weld seams in 3R composites. The team repaired delaminations by heating the defect area to the repair temperature of 220°C and applying a constant consolidation pressure of 20 bar while keeping the temperature constant.

The Composites and Smart Materials Lab (CSML) at University of Ioannina (Ioannina, Greece) evaluated this repair technique as successful using mechanical testing as well as various nondestructive evaluation (NDE) techniques including phased array ultrasonics, infrared thermography, acoustic emission, impedance spectroscopy and electrical resistance change method (ERCM). This innovative multi-platform NDE methodology provided in-depth damage detection and key information about the evolution of the damage process.

In terms of repair efficiency, from ILSS tests, the 3R composites exhibited a 72% recovery of their initial mechanical properties after repair and a recovery of ≈90% in low-velocity impact tests at 9 and 15 joules of impact energy.

Recycling and AIRPOXY 2

Although recycling is not being addressed within the AIRPOXY project, CIDETEC has demonstrated that scraps can be ground and remolded, for example, using compression molding at 210°C. However, similar to the process used by Connora, 3R laminates can also be immersed in a solution containing a mild reducing agent that, as Rekondo explains, “disrupts the dynamic network and therefore dissolves the resin, enabling it to be precipitated out and recovered as a powder.” She notes this dissolution process can be accelerated by heating at temperatures up to 100°C. “The powder could be then reused for a second composites application, but this is still undergoing research,” says Rekondo.

Fig. 4. Mechanical recycling and remolding

An alternative route to dissolving 3R resins, composites can be ground into flakes or pellets and remolded by heating to 80°C above Tg and pressing to form a new short-fiber composite.

“For recycling of scraps, we think two to three cycles will be possible,” she continues. “But for real end-of-life applications, there will always be weathering of the part and other degradation of the material after being in service for many years. In these cases, we think no more than one recycling will be possible. The second application of the material will be OK, but probably not a third. This is part of what we are testing now, first for industrial-grade 3R resins, as we complete the full characterization of 3R materials.”

The two demonstrators will also be completed this year, says Markaide. “We will then proceed with mechanical testing of these, including damage and repair assessments. Our goal is to reach TRL 5 by the time we finish in 2022.” And then what? “We plan to have another project, AIRPOXY Part II,” she says, “to continue optimization of the processing and continue with mechanical characterization, as well as validation and certification of materials and processes. We will need a second project to push the technology to market.”

The ability to thermoform and weld epoxy aerospace parts seems a technology practically made for urban air mobility. “We have to think now how to provide what those sectors will need,” adds Markaide, noting that a roadmap for commercialization will indeed be one of the deliverables in AIRPOXY Part I. “Recycling is also a necessary solution that is not yet required for composites, but it will be in the future. We want to be ready.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Reprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More