Work In Progress

3D printing and AFP join forces in automotive demonstrator

Bavarian auto industry and TU Munich research how to reduce molding costs by combining continuous fiber and 3D-printed composites.

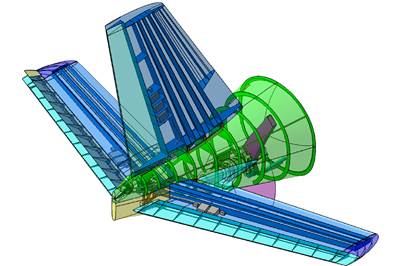

WatchMulti-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

WatchHigh-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

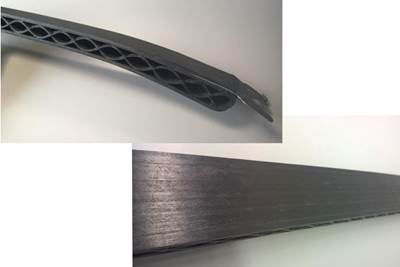

Read MoreMulti-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

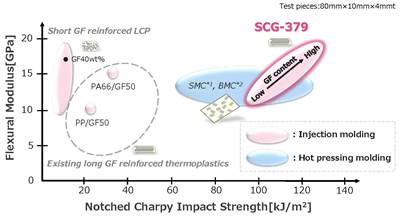

Read MoreLong-fiber liquid crystal polymers

High-performance, injection moldable grades to be offered with long glass, carbon fiber options.

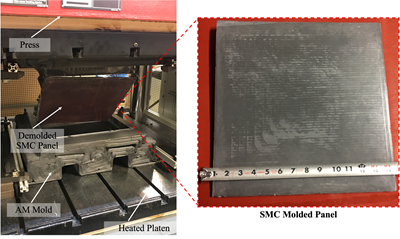

Read MoreCan 3D printing debottleneck prototype tool production?

Preliminary IACMI/ORNL study evaluates viability of using polymer additive tooling to compression mold SMC.

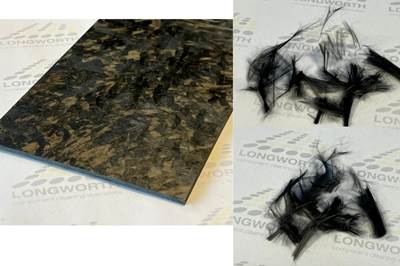

Read MorePressurized steam-based composites recycling for full fiber reclamation

Longworth’s DEECOM process for composites recycling claims to produce intact fiber and resin reclamation with near-virgin properties.

WatchEnvisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

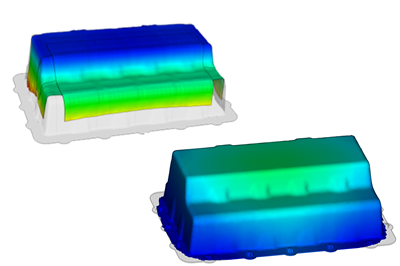

Read MoreHybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

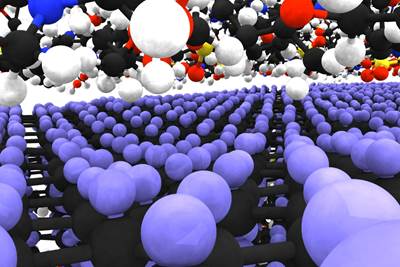

Read MoreNASA Institute develops carbon nanotube-based composites for Mars spacecraft

The five-year project employs computational modeling techniques to build composite panels that are three times stiffer and stronger than current carbon fiber to enable manned missions to Mars.

Read More