First 3D woven composite for NASA thermal protection systems

A NASA-led team develops 3D woven quartz preform, hybrid process to infuse it with cyanate ester resin (0.5% voids) and achieves TRL5 in three years to replace CF/phenolic in the Orion spacecraft’s compression pads.

3D woven quartz preform helps to boost performance in the compression pads, part of the thermal protection system (TPS) for the Orion spacecraft. SOURCE: NASA

Orion

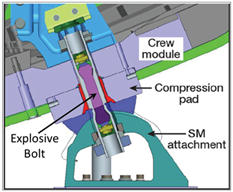

NASA’s Orion Multipurpose Crew Vehicle has been designed to transport a crew of six to and from deep space, including an asteroid (≈2025) and Mars (≈2030). It comprises two modules: the Crew Module (or Command Module, CM), built by Lockheed Martin (see Sara Black’s article on its composite heat shield) and the Service Module (SM) built by Airbus Defense and Space for the European Space Agency (ESA).

In Dec. 2014, the Orion first flight test vehicle, EFT-1, was successfully launched on a Delta IV heavy rocket, reached an altitude of 5,793 km above earth, achieved speeds of 20,000 mph, and withstood temperatures over 2,200°C during reentry. However, the heat demands of this mission were much lower than what Orion will see when it goes further out, for example, to Mars.

Need for Better Compression Pads

Many lessons were learned during that test, including the need for improved ablative materials for the compression pads which enable attachment of Orion’s CM and SM. These pads — six total used on the EFT-1 spacecraft, redesigned now to total four for future Orion models — measure roughly 280 mm in diameter and 76 mm thick, and must resist launch & ascent loads and pyro-shock (explosive bolts) during CM/SM separation, as well as meet reentry demands for high-temperature resistance and ablation.

Orion’s compression pads enable attachment of the Crew and Service Modules (left) and must resist structural loads during launch and ascent, as well as pyro-shock during CM/SM separation. Explosive bolt and CF/phenolic compression pad (center). Six compression pads were evenly spaced around the Orion CM’s blunt body heat shield for EFT-1 (right).

SOURCE: Jay Feldman, NASA Ames.

Ablative materials are solid substances which undergo a series of physicochemical transformations to control heat transfer. In other words, they keep underlying structures cool by managing energy as the materials are consumed through melting, vaporization, oxidation, sublimation and spallation. Ablative materials are a key part of a spacecraft’s thermal protection system (TPS), and are commonly made from fiber-reinforced composites. The compression pads discussed here are an important part of the overall TPS design for Orion. (NASA describes Orion’s composite ablative heat shield here.)

|

SOURCE: NASA.

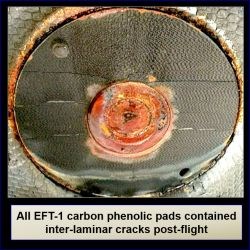

The carbon fiber/phenolic compression pads on the EFT-1, however, were expected to fail due to poor interlaminar strength unless a steel insert was added to handle some of the structural loads. The insert, which surrounds the explosive bolt, has significantly higher thermal conductivity than the composite, creating a thermal “short” in the TPS.

3D Solution

As a leader in NASA’s heat shield materials research and development, Jay Feldman had already been pursuing an internal R&D program exploring 3D woven fabrics for TPS solutions for subcontractor Analytical Mechanics Associates, Inc. (AMA, Hampton, VA, US) at NASA Ames Research Center (Mountain View, CA, US). Feldman led the project “3D Multifunctional Ablative TPS (3D-MAT) for Orion Compression Pad” which began in 2012. The goal was to overcome the traditional interlaminar weakness of 2D laminates and also eliminate the need for metal inserts to receive the bolts.

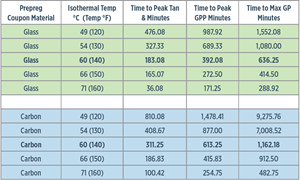

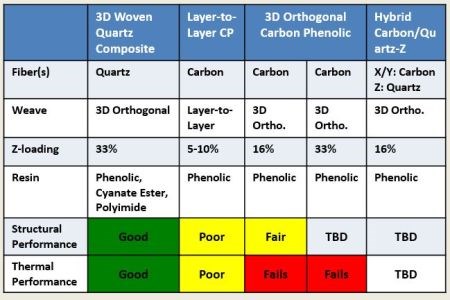

NASA Ames’ 3D-MAT program trialed different fiber and resin combinations before selecting 3D woven quartz and cyanate ester. SOURCE: Jay Feldman and NASA Ames.

A variety of fiber and resin combinations were trialed, with the compression pads’ structural and thermal requirements driving final selection:

- 3D orthogonal weave enabled high fiber volume (57%) for structural robustness;

- Fused quartz fiber provided high temperature capability with low thermal conductivity;

- Low viscosity cyanate ester resin system allowed hybrid resin infusion/resin transfer molding (RTM) processing to achieve full densification of large 3D woven preforms.

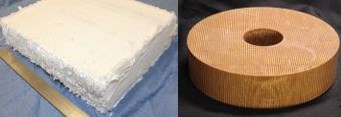

3D-MAT’s new approach uses a straight orthogonal 3D woven quartz material from Bally Ribbon Mills (Bally, PA, US), woven continuously at 76 mm thick and 305 mm wide using a jacquard loom (click here to learn more about 3D weaving). “This is the first application of a 3D woven material in a TPS application for NASA,” says Feldman, ceding that the Dept. of Defense has used 3D carbon/carbon composites in missiles systems. He notes that the 3D architecture places one-third of the fiber in each direction: x, y and, notably, z (through-the-thickness). “One of the challenges was scaling up the weaving process to increase the cross-sectional area by a factor of four in a continuous process,” says Feldman. The next challenge was how to infuse the fabric with cyanate ester resin from TenCate Advanced Composites (Morgan Hill, CA, US) and fully densify it to meet ablation requirements.

Bally Ribbon Mills was able to scale up the 3D preform cross-section by 400% in a continuous process using NASA-funded hardware. San Diego Composites then developed a modified RTM process to infuse the preform with resin. SOURCE: Jay Feldman, NASA.

Hybrid RTM Infusion

To overcome this challenge, Feldman and team worked with San Diego Composites (SDC, San Diego, CA, US), a well-known manufacturer that is making a number of parts for Orion, including the ogive and launch abort system (LAS) fillet. As described in the video below by SDC chief technology officer Ken Mercer, the very dense 3D preform was placed into tooling that evacuated air first, and then injected the resin under pressure.

(click here to play video from beginning)

Feldman says the process started with a vacuum soak, followed by resin infusion, cure and post-cure. So, as Mercer says in the video, the process is more like infusion than traditional RTM, although pressure is used to achieve the final low void content. “Less than 2% voids was the limit,” notes Feldman, “but we were able to achieve 0.5%, thanks to SDC’s process development.” SDC then machined and supplied the final circular compression pads.

EM-1 and New Applications

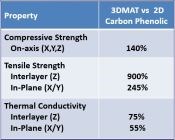

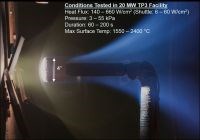

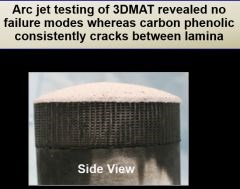

Before SDC proceeded with compression pad production, a full suite of thermal and structural model development was completed, as was tension, compression, thermal conductivity and creep testing, arc jet testing to simulate reentry conditions and testing to simulate pyroshock during CM/SM separation. The 3D-MAT quartz/CE compression pads showed significant material property improvements vs. the CF/phenolic material used in EFT-1 and also resisted the interlaminar cracking that plagued that material.

The 3D-MAT solution achieved significantly improved properties vs. the CF/phenolic material used in EFT-1, resisted interlaminar cracking and achieved TRL5 within three years.

SOURCE: Jay Feldman, NASA.

SDC has now delivered 31 compression pads to NASA for use on Exploration Mission-1 (EM-1) and also in further TPS solutions development. EM-1, which is the second flight test and first time all Orion systems will be operational, is currently scheduled for 2018, but must undergo significant testing first. A crewed Orion atop the SLS will launch from a newly refurbished Kennedy Space Center in 2023, making it the first fully integrated mission of NASA’s deep space program.

Feldman considers 3D-MAT an innovative success, reaching TRL5 in just three years: “We went from concept to built flight hardware in that short timeframe.” He adds that the Orion team is so happy with the material’s performance that it is extending use of the 3D quartz/CE composite to various parts of the vehicle back-shell. Meanwhile, Feldman and his team are continuing to look at how 3D composites can be used to provide other TPS solutions. One example is the Heat Shield for Extreme Entry Environment Technology (HEEET) for Planetary Entry Probes project, which tailors the preform to achieve a higher-density surface layer and lower-density insulating layer made with blended carbon/phenolic yarns.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreCSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More