Gurit features core materials, adhesives, resins, molds for wind, aerospace

Gurit is featuring its offerings and expertise for wind energy, composite tooling and lightweighting applications such as aerospace, rail, healthcare and marine.

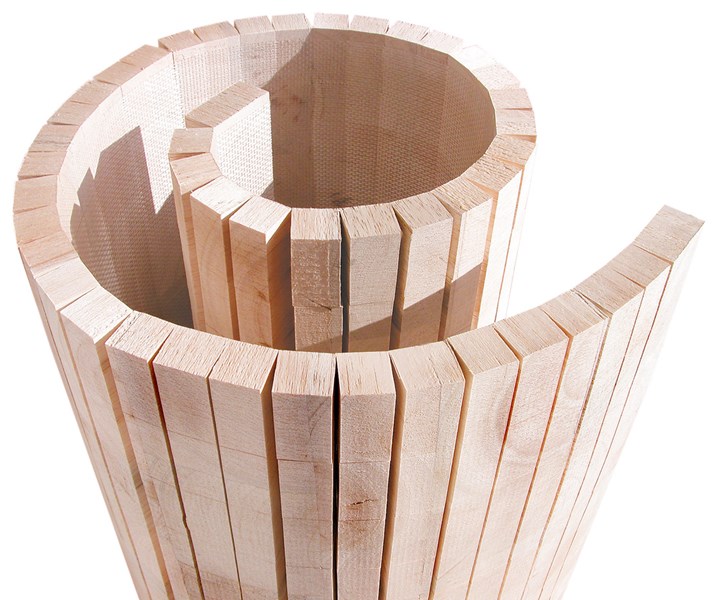

Gurit’s Balsaflex balsa core material. Source | Gurit

Editor’s note: CompositesWorld received several new product and technology announcements ahead of JEC World 2020, which had been scheduled for March 3-5. Although that exhibition was postponed to May, CW is now publishing the announcements we received. This is one of them.

Gurit (Zurich, Switzerland) is featuring its offerings and expertise for wind energy, composite tooling and lightweighting applications such as aerospace, rail, healthcare and marine.

Gurit’s sustainable core materials solutions for wind turbine blades are demonstrated with Gurit’s Kerdyn Green and Balsaflex core materials. Kerdyn Green is a highly adaptable, recyclable, thermoplastic core material with a good balance of mechanical properties, temperature resistance, density and cost for a wide range of applications and processes. The core is produced from up to 100% recycled PET materials and suitable for use in wind energy but also in marine, industrial and transportation applications. Gurit Balsaflex is a classic end-grain balsa wood core made from renewable resources, featuring very high strength-to-weight ratio.

Spabond 840 is a certified, high-performance, toughened adhesive designed for bonding large structures such as wind turbine blades. The chemistry is said to deliver a step change in curing profile, enabling both long working times and rapid curing. As a result of its low toxicity resin matrix, Spabond 840 is said to be beneficial from a health and safety point of view.

Gurit provides wind blade manufacturing automation solutions, including molds and different types of hinge arms suitable for various mold shapes and sizes to safely and precisely close the two halves of a mold.

The Renuvo system is a range of UV-curing lamination materials developed by Gurit for the repair of wind turbine blades and other industrial applications. For the worldwide distribution of Renuvo, Gurit has signed a new distribution agreement with AeroNordic ApS. Supported by its ability to handle small volumes at short notice, AeroNordic offers a complete package including improved ancillaries, training and validation processes for Renuvo customers.

Gurit’s complete composite solution reportedly enables lightweight boat designs. Typically, a range of different materials are combined in order to reach the best level of durability, quality and performance for the purpose of a specific boat. Gurit’s prepreg, formulated and core materials complemented by Gurit’s vast engineering knowledge and in-house expertise enable innovative and customized solutions.

For the aerospace industry, Gurit is showcasing two typical applications: an aircraft air-conditioning ducting solution and a winglet. Gurit’s qualified range of cyanate ester resin-based FST prepregs are said to demonstrate a unique combination of properties, combining excellent mechanical performance and the fulfillment of the highest international JAR/FAR fire protection regulations regarding fire, smoke, toxicity (FST) and heat release.

Gurit has started a collaboration with Bcomp (Fribourg, Switzerland) a high-tech start-up that specializes in sustainable lightweighting materials using natural fibres. Bcomp’s proprietary powerRibs technology and ampliTex range of technical fabrics are extremely light weight natural fiber reinforcements. Gurit is Bcomp’s official distributor for the marine industry and now sells ampliTexT and powerRibs, often in combination with Gurit’s accredited bio-based resin solutions.

Gurit is a finalist for the JEC Innovation Awards in partnership with Comaxel for the Norsepower Rotor Sail Solution. This innovation helps freight and passenger vessels to reduce fuel costs by 5-30%, enhancing the propulsion system of a vessel by using wind as an auxiliary propulsion measure.

Meet Gurit CTO Emiliano Frulloni at the JEC World Technical Conferences. In the "Eco-design, sustainability and recycling: where are composites?" session he will talk about sustainable core materials and how PET bottles are recycled into wind turbine blades. The presentation will take place on Tuesday, March 3 at 11:15 a.m.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More