Digital workflows optimize material yields, design and productivity

CAMX 2024: TruComposites and Evolv GMP digital manufacturing solutions by Magestic Technologies drive efficiencies and precision across composites manufacturing disciplines.

Share

Magestic Technologies (Pearl River, N.Y., U.S.) showcases the latest updates to to its digital manufacturing solutions, Evolv GMP and TruComposites, which elevate material yields through improved nesting processes and optimize entire manufacturing workflows like hand layup and AFP/ATL with advanced AI and genetic algorithm capabilities.

Evolv GMP is designed to transform operations across various industries, including aerospace, energy, transportation and automotive. According to the company, it ensures versatility and effectiveness in diverse industrial settings. In addition, TruComposites is a comprehensive software solution tailored specifically for composites materials manufacturing.

Magestic’s goals are to enhance efficiencies and precision across composites manufacturing disciplines. The company’s available technologies achieve this through:

- Customized manufacturing solutions: Magestic software solutions offer flexibility and reliability. With streamlined integration, they are designed to adapt to diverse production environments for complex manufacturing needs.

- Generative AI and genetic algorithms: These updates increase nesting yields, reduce material waste and improve production efficiency. The technologies are engineered for high-stress and high-performance applications, maximizing resource utilization and minimizing costs.

- All-in-one materials platform: Magestic Technologies’ TruComposites platform enables multi-discipline performance in processes like hand layup, AFP/ATL, kinematics simulation, composites design and more.

Attendees have the opportunity to test the latest builds of the company’s flagship software, Evolv GMP, exploring its various features, including Magestic’s AI-driven process optimization and genetic algorithm enhancements. Additionally, TruComposites is available for viewing firsthand.

Related Content

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

Winding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Related Content

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreWinding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreHigh-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreRead Next

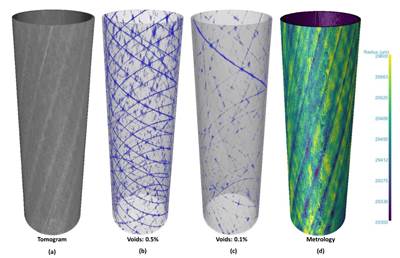

Multi-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreJetcam releases JOC 4 nesting software update

JOC 4 is the first of several major product releases this year that continue on the path of automation, integration and simplifying the performance of complex operations.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More