Modular AFP automation family supports adaptable production handling

CAMX 2024: Broetje-Automation’s Staxx family of AFP solutions create an ecosystem of functionality, versatility and scalable automation.

Share

Broetje-Automation (Rastede, Germany) announces solutions for smart automated fiber placement (AFP) automation — from prototype to large-scale production. The star of the show, the Staxx One, is a transportable AFP cell designed for simple, plug-and-play handling. Demonstrations take place twice a day, highlighting the system’s various functions, versatility and scalable automation.

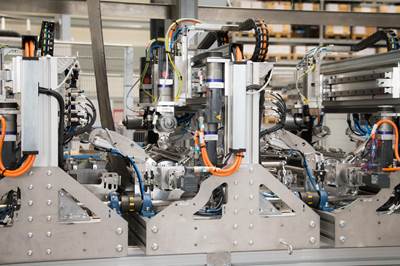

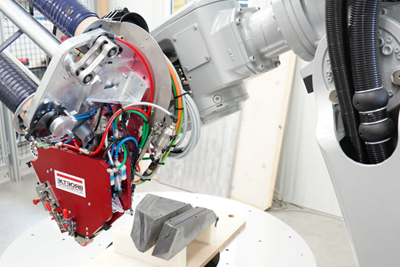

From the highly compact and cost-effective Staxx Box to the high-performance capabilities of the 16-tow robotic Staxx Flex system, each member of the Staxx family represents one specific building block to form an ecosystem of modular AFP automation.

The Staxx Box is designed for layup tests, material qualification and small parts, while the Staxx One single-tow robotic system can add additional flexibility — it can be mounted on an industrial robot while using the same AFP end effector as the Staxx Box. The large, 16-tow AFP system, Staxx Flex, is designed for layup of complex and large structures, while the Staxx Compact focuses on high-rate production capabilities.

The Staxx family shares many system components due to its modular design and an integrated software backbone. Therefore, a wide range of different fiber placement applications and materials are covered to serve the individual needs of each customer. Through the AFP systems’ Factory of the Future focus, Staxx targets AFP optimization through enhanced precision, efficiency and reliability for composites manufacturing.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Broetje-Automation, Spirit complete CCPS project for automating aircraft preform production

Continuous composite preforming system (CCPS) integrates all work steps, from the roll to the stringer, in a fully automated, smaller footprint process, taking the next step for future aircraft programs.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More