Resin formulations, prepreg development modifiable to customer specifications

CAMX 2024: TCR Composites is a global prepreg supplier, offering continuous tow/roving, woven and stitched fabrics, braided sleeves and UD tapes.

Share

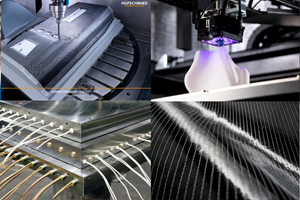

TCR Composites Inc. (Ogden, Utah, U.S.) highlights its various TCR prepreg offerings. Formulated with distinctive thermoset epoxy resin systems, they feature a range of shelf lives — from 1 month to 1 year — storable at room temperature (~24°C/75°F) and without the need for refrigerated shipping. These resins are currently used to manufacture prepreg in the following forms: Tow/roving, unidirectional (UD) tape and woven fabrics. They can be customized to meet design and processing requirements for many different industries.

TCR prepreg tow (towpreg) is the material of choice for clean filament winding, from high-performance rocket motor cases to quality commercial pressure cylinders. TCR towpregs are designed for high throughput (up to 900'/275 m per min) to simplify and provide additional process efficiencies.

Tow/roving use 3-60K standard modulus to high-modulus fibers, as well as glass, basalt and aramid with equivalent cross-sections. TCR resins and fiber are matched to provide optimal performance. According to the company, each fiber has distinctive properties and therefore may require a specific resin system to achieve maximum performance.

TCR prepreg fabrics are available in many styles, weights and widths (up to 1,270 mm/50"). Common fabrics are often stocked on-site, while specialty fabrics are obtained from suppliers and manufacturers worldwide. Fabrics, also referred to as “broad goods,” are used in a wide variety of markets including medical, industrial, infrastructure, aerospace, automotive and recreation. Available fabric forms include carbon fiber, glass, aramid and quartz.

The company also specializes in the manufacture of UD prepreg tapes, made in a range of weights (180-600 gsm) and thicknesses to meet customer requirements. TCR UD tapes are ideal for fabricating composite products that require long layup times and thick laminate construction.

TCR Composites also highlights prepreg braid offerings, such as tubular sleevings. These braids may be used for aerospace, medical, recreational and industrial applications. TCR prepreg braids have low “tack” to facilitate the opening of a tubular sleeve, to apply to a molding or tool. They are available in carbon, glass and aramid fibers.

Related Content

-

CAMX 2023 Show Daily: Thursday, Nov. 2

CW is reporting live on the CAMX show floor in Atlanta, Georgia. Download today’s Show Daily covering interesting exhibitors and technologies, the committee members and volunteers that make the show possible, “Good Day, CAMX” results and a look back at show floor activities.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Related Content

CAMX 2023 Show Daily: Thursday, Nov. 2

CW is reporting live on the CAMX show floor in Atlanta, Georgia. Download today’s Show Daily covering interesting exhibitors and technologies, the committee members and volunteers that make the show possible, “Good Day, CAMX” results and a look back at show floor activities.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreCAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRead Next

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreNet-shape machining services available for structural foam core

CAMX 2024: In addition to its distribution of various product materials for the composites industry, Technology Marketing Inc. now assists in machined net-shaped Rohacell structural foam core to customer requirements.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More