Composites Curing

Curing in composites refers to the process where the composite materials, typically comprised of a resin matrix and reinforcing fibers, undergo a chemical reaction or heat treatment to solidify and form the final desired shape and properties. This stage is critical as it transforms the raw materials into a durable and structurally sound composite. Curing methods vary based on the type of matrix—whether it's a thermosetting resin like epoxy or a thermoplastic resin. Heat, pressure, or a combination of both are often applied during curing to activate the chemical reactions that cross-link the molecules within the matrix, creating a robust bond between the fibers and the matrix.

Latest Curing Articles

VIEW ALLUavos upgrades composite curing ovens with controller software

A standard operating mode and a program operating mode with 19 pre-programmed options are now available to advance precise temperature control.

Read MoreWisconsin Oven ships curing oven for filament-wound composites

Gas-fired batch oven is designed to process up to 5,000 pounds of filament-wound parts at a time, while delivering on optimal temperature uniformity and efficient use of floor space.

Read MoreTPI, University of Texas participate in wind blade cure optimization project

Physics-informed machine learning algorithms will be applied to simulate and optimize composite wind blade curing in an effort to advance smart composites manufacturing in industry.

Read MoreHigh-quality heat treatment, lab equipment for simplified operation

CAMX 2024: Across International is showcasing an array of heat and laboratory materials, including drying ovens, high-temperature furnaces and a bladeless mixing solution.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

WatchUV curing systems save composites curing time, energy

CAMX 2024: IST America presents a comprehensive selection of UV, IR and hot air technologies, designed to deliver results in less than a minute.

Read MoreKnowledge Centers

CompositesWorld’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Curing News And Updates

Formable, reusable tooling achieves complex composite parts

CAMX 2024: Hawthorn Composites is displaying an inner and outer tail boom and a multi-chamber composite trailing edge control surface, enabled via its Smart Tooling solution.

Read MoreVOC-free UV curing prepregs, putties and primer provide effective repair, bonding

CAMX 2024: Sunrez Corp. presents its product line for UV curing, all crafted without VOCs or HAPs for reduced emissions.

Read MoreHardener accelerator line designed for epoxy resin optimization

CAMX 2024: Alzchem highlights the Dyhard series of latent curing agents, providing the balance of mechanical and thermal properties formulators need for thermoset epoxy resin systems.

Read MoreCuring ovens ensure coverage of composite heating needs

CAMX 2024: Composite curing ovens by Wisconsin Oven provide a variety of features for comprehensive support, including temperature uniformity, energy efficiency, advanced controls and IoT, all backed by a dedicated team.

Read MoreUavos delivers curing oven to aerocomposites manufacturer

Composite curing oven meets customer needs with ability to cure complex synthetic and composite parts.

Read MoreAbaris selects Premier ESR to optimize composite cure cycles

Encapsulated sample rheometer (ESR) by Alpha Technologies will be incorporated into Abaris’ service and consultation business to characterize a variety of composite material specimens.

Read MoreFeatured Posts

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

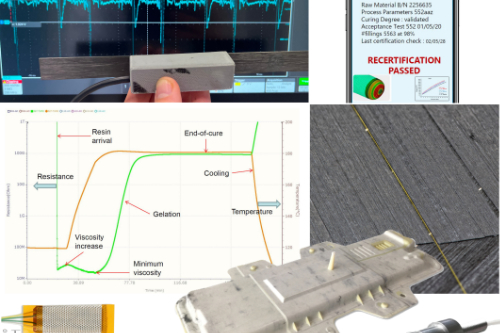

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

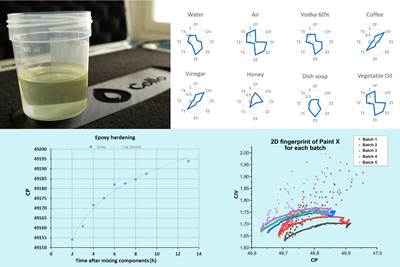

Read MoreFingerprinting liquids for composites

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

WatchPlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read More