Composites Use in Marine Applications

Infused, fiberglass/polyester composite boat hulls have been built since the mid-1900s, expanding over time to include additional resins and foam cores. Composites continue to be a mainstay for various types of boats and luxury and racing yachts, and now include newer innovations such as carbon fiber precision hydrofoils and recycled carbon fiber or bio-based resins.

Latest Marine Articles

VIEW ALLMiniLab consortium produces first full-scale thermoplastic composite hydrofoils

Project advances toward first recyclable foils for ocean racing, part of “Infinite Foil” finalist for JEC Innovation Award 2025.

Read MoreComposites end markets: Boatbuilding and marine (2025)

As 2023-2024 consumer demand slows, boat and marine vessel manufacturers continue to focus on decarbonization and new technologies using composites.

Read MoreBreton companies launch recyclable hydrofoil design project

Development and testing of recyclable, thermoplastic composite hydrofoil structures in Foil Infinity are expected to equip offshore racing yachts by 2030 and potentially even aircraft in the future.

Read MoreDiab expands buoyancy services through SCS acquisition

Global composite subsea buoyancy services are strengthened and broadened with Subsea Composite Solutions’ expertise.

Read MoreLarge-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

WatchMerConcept, Extracthive integrate rCF components into racing yacht construction

Development and integration of recycled composite ballast dorade vents for an IMOCA class yacht and other ongoing projects demonstrate a push for greater circularity in the marine industry.

Read MoreKnowledge Centers

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Marine News And Updates

Base Materials subsea buoyancy foams earn DNV type approval

Low-density syntactic foams have been qualified for use in 11,500-meter ocean depths in addition to approval of manufacture.

Read MoreBio-based composite Skaw A foiling scow yacht is built with Greenpoxy resins

Sicomin has partnered with Skaw Sailing and Shoreteam to deliver a foiling yacht design for cruising that embodies durability and performance with a low environmental impact.

Read MoreSunreef Yachts completes 43-meter single-shot hull infusion project

Sunreef 43M Eco electric catamaran, with a composite surface of 1,700 square meters, is considered to have the world’s largest infused hull.

WatchMarineShift360 project launches new initiatives for marine industry sustainability

Life cycle assessment (LCA) tool and Industry Accelerator and University Outreach programs are designed to fast-track decarbonization as regulatory frameworks tighten and consumer demand for sustainability grows.

WatchORPC Ireland, Queen’s begin X-Flow project for hydrokinetic turbine testing

Deployment of CFRP turbine technology to Strangford Lough will provide insight into blade and rotor performance, predictive maintenance and grid-scale benefits of tidal energy using real tide conditions.

Read MoreNlcomp is selected as a World Sailing award finalist for rComposite

Third World Sailing award nomination highlights the company’s focus on marine innovation using sustainable composite materials.

Read MoreFeatured Posts

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreFinnish boatbuilder balances history, innovation in fiberglass composites design

CW Top Shops honoree Sargo Oy shares its successes in upgrading operations from hand layup to infusion, employing low-waste manufacturing practices, research in large-format 3D printing for mold production and more.

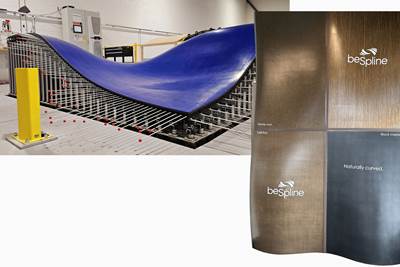

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreFAQ: Marine

How are composites used in boatbuilding?

Boats and yachts have featured fiberglass composite boat hulls, decks and other structures for many years. These are typically fabricated via infusion, hand layup and/or sprayup methods. Carbon fiber/epoxy can be used in applications requiring even lighter weight to increase speed or fuel efficiency, such as in sailing boats or racing boats.

More recently, new international regulations have allowed developments in composite decks, superstructures, rudders and other components for large ships as well.

Why use composites in boatbuilding and marine applications?

- Composites are attractive in marine applications due to corrosion resistance, as well as lightweighting that composites can provide compared to metals or wood can reduce fuel use, greenhouse gas emissions and vessel draft, helping to improve sustainability.

- Source: Removing barriers to lightweighting ships with composites