Composites Resins

Resins play a pivotal role as the matrix material in composite structures, bonding and encapsulating reinforcements like fibers within the composite. These materials, commonly in liquid form before curing, undergo a transformation into a solid, durable substance. Resins vary widely in type, such as epoxy, polyester, vinyl ester, and more, each offering distinct properties like adhesion, flexibility, and temperature resistance. The selection of resin significantly influences the composite's final characteristics, including strength, durability, and chemical resistance.

Latest Resins News And Updates

Bio-based composite Skaw A foiling scow yacht is built with Greenpoxy resins

Sicomin has partnered with Skaw Sailing and Shoreteam to deliver a foiling yacht design for cruising that embodies durability and performance with a low environmental impact.

Read MoreBelzona highlights composite wrap system designed for aqueous environments

Belzona 1984, a surface-tolerant epoxy resin, enables repair and restoration of holed, weakened and corroded pipe and tank walls that are damp, wet or underwater.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

Read MoreToray Advanced Composites expands continuous fiber TPC capacity, capabilities

Assets, technology and IP acquisition of Colorado-based Gordon Plastics will enhance Toray’s product portfolio, growing its ability to support emerging markets in thermoplastic composites.

Read MoreKraussMaffei expands composites, plastics capabilities at Brighton, Michigan facility

The site recently installed a powerPrint large-format AM system, thermoforming machine and more to serve customers in North America.

Read MoreRoboze supports F1 composite brake cooling duct manufacture

Carbon fiber-reinforced PEEK composites, 3D printing services improve production time and costs of complex motorsport parts for Visa Cash App RB F1 team.

Read MoreFeatured Posts

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

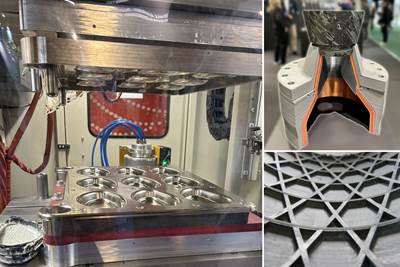

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

WatchCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Watch“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreFAQ: Resins

What is a resin?

A solid or pseudo-solid organic material, generally of a high molecular weight. In fiber reinforced plastics, it is the resin that binds the fibers.

Source: Essentials of Advanced Composite Fabrication & Repair - Second Edition

What are the major groups of resins?

Thermoplastic and Thermoset resins.

What is a thermoplastic resin?

Polymers or copolymers that essentiall have no cross-links and can be melted or reshaped when heated to melt point or above the Tg.

Source: Essentials of Advanced Composite Fabrication & Repair - Second Edition

What is a thermoset resin?

A plastic that cures by the application of heat or by chemical reaction resulting in a cross-linked insoluble molecule; considered an irreversible process.

Source: Essentials of Advanced Composite Fabrication & Repair - Second Edition

.jpg;maxWidth=300;quality=90)