500,000 parts per year? No problem!

BENTELER-SGL develops fully automated HP-RTM production of the weight- and space-saving composite leaf spring for Volvo’s multi-model SPA global platform.

Founded in 2008 as a joint venture between automotive Tier 1 supplier BENTELER Automobiltechnik (Paderborn, Germany) and fiber-based solutions provider SGL Group (Wiesbaden, Germany), BENTELER-SGL (Ried im Innkreis, Austria) manufactures a variety of fiber-reinforced automotive composites, including side blades and pillars, doors, spoilers and seats. But its most noteworthy achievement, thus far, is its expertise in mass production of composite leaf springs. Since it acquired the automotive business unit of Fischer Composite Technology, also located in Ried im Innkreis, and built a second composite parts plant in nearby Ort im Innkreis in 2012, the company has innovated its way to unprecedented autocomposites production capability.

By 2013, BENTELER-SGL had replaced the then typical epoxy matrix and demonstrated a glass fiber/polyurethane front-axle leaf spring for Daimler’s (Stuttgart, Germany) Mercedes-Benz Sprinter van, which slashed weight 65% vs. steel (6 kg, down from 15 kg).

Working with Henkel's (Düsseldorf, Germany) fast-curing LOCTITE MAX 2 polyurethane (PU) resin and the high-pressure resin transfer molding (HP-RTM) process, BENTELER-SGL was able to achieve production volumes of 100,000- 150,000 parts/yr (see Composite leaf springs: Saving weight in production suspension systems).

The company is preparing to raise the bar again as it ramps production of a glass fiber/PU rear axle leaf spring for Volvo’s (Gothenberg, Sweden) new XC90 crossover SUV, the first vehicle produced on the automaker’s new global platform, called Scalable Product Architecture (SPA). As an integral part of SPA, the spring also will be used on the S60, S90, V60, V90 and XC60 and any larger model that might be developed.

“This is the highest volume composite parts project in the automotive industry, reaching 500,000 parts/year in 2018,” claims BENTELER- SGL managing director Dr. Robert Ernst-Siebert. “In addition to the comprehensive expertise of our partners BENTELER and SGL, a strong partnership with the customer as well as with our resin supplier has been key, as we adapted our existing HP-RTM and preforming process into a fully automated production line with no manual steps. We have developed a process that was not existent in the marketplace.”

Multi-model design

As BENTELER-SGL worked with Volvo on the SPA leaf spring design, it drew from a wide range of experience. “We had capability from the Sprinter van leaf springs but also with other suspension system components via the BENTELER Automotive group,” explains Ernst-Siebert. “All of this was incorporated into the Volvo leaf spring program.”

The design of each leaf spring is determined by its function and requirements, explains Frank Fetscher, business development director of FRP chassis applications for BENTELER Automotive. In turn, this design determines the leaf spring performance and cost. The leaf spring design for Volvo uses up to 60 plies of glass fiber unidirectional fabric, which according to Fetscher, meets performance, durability and cost requirements, as well as very tight package constraints. Although the composite spring is roughly the same size as the previous metal version, it enables elimination of coil springs and suspension struts so that the axle protrudes less into the trunk area, freeing up cargo space.

“Based on the material properties, there were limits to the design,” he explains. That said, the performance and package needs of all models, from the luxury XC90 down to the compact X60, had to be met in one leaf spring design, of one length and one width — 1,200 mm by 60 mm. However, the weight of the SUV vs. the smaller sedan models can vary significantly. Thus, three variations in curvature were designed to enable the appropriate spring per vehicle weight. The main targets of lift force and stiffness for different vehicle variants can be adapted by moving the upper and inner bushings outward on the one hand and by using different spacers at the end of the spring on the other, offering additional ability to tune the spring performance for each model’s needs while keeping the production process as simple as possible. Thus, BENTELER-SGL was able to manage a significant amount of applications complexity. “Volvo developed with us this ability to adapt the spring rate across the different models,” says Fetscher.

Validation of the design and of the final production process was achieved per the Volvo-supplied specification. “We supported them with ideas on how to verify and validate,” says Fetscher, adding that those involved both computer-aided engineering (CAE) and physical testing. “We also transferred their specifications into our CAE fatigue programs and physical fatigue testing.” He notes this includes dynamic fatigue load cases derived from road load data cases, as well as static load tests, all of which are performed under different environmental conditions. Fetscher adds that comparable testing is completed for all BENTELER Automotive and BENTELER-SGL chassis components, such as anti-roll bars or lower control arms, and provides a good prediction of the part’s service life.

Precision preforming

Produced in the Ort im Innkreis facility via HP-RTM, the Volvo leaf springs use the LOCTITE MAX 2 polyurethane resin. But the higher annual production volume target necessitated a new level of automation. “The raw materials come in, and all of the process steps are automated, without manual intervention,” Ernst-Siebert reiterates. “This line was developed in-house and is key to our success in achieving high quality in the final component.” As such, it is understandable that BENTELER-SGL is not ready to reveal many details.

The first part of the line comprises automated cutting and preforming of the unidirectional reinforcements. It is also an area that demonstrates the production control system. “We have full control of the line, including automated inspection,” Ernst-Siebert explains. “There are different quality assurance steps throughout the line — not only visual inspection but also automated mechanical testing. Every leaf spring is tested.” Fetscher adds that this testing checks spring stiffness and 100% function of the part, a standard practice for this type of application.

Crucial to a stable, robust process and reproducible parts, insists Ernst-Siebert, is what he calls inline parameter control of all materials. Fetscher gives an example: “In the case of a preform where one ply is out of place, the system detects this mismatch between inspected and programmed parameters, so that we know immediately the location of the problem. We then remove the non-conforming part and make modifications to ensure that part of the line is corrected.” He says that in the future, BENTELER-SGL will move toward a self-controlling line, “This is our first step in that direction, toward an integrated Industry 4.0 system.”

Preforming is done in the automated line’s next section. The plies of UD fabric are first stabilized, using industry state-of-the-art epoxy- or polyurethane-based powder binder. Heat and pressure are applied to melt the binder so that the preform is stabilized as it cools. Multiple preforms, one per spring, are then transferred simultaneously by robot into the multi-cavity lower tool in the HP-RTM press. “We have developed special grippers for all such transfer steps as part of our proprietary internal development,” notes Fetscher.

“Thanks to SGL, we have performed a great deal of R&D to define the best material concept for this specific leaf spring application, including textiles and binders,” Ernst-Siebert points out. “It’s not as simple as it looks. Only certain textiles perfectly fit. The material combination for the leaf springs developed by SGL, for example, was specifically designed not only to maximize the part’s ability to meet functional requirements but also to provide a stable preform.”

Refining resin injection

When the preforms are placed, the tool is closed and resin injection begins. However, achieving the final robust automation of HP-RTM required significant development. “The key is optimization of the process,” Ernst-Siebert asserts. “You must have deep understanding of the resin, which we have through Henkel, and also the textile, which we have through SGL. So we know how to adjust the parameters to meet the cycle time and achieve production.”

“There were two key challenges,” says Frank Kerstan, global program manager in the Adhesive Technologies business unit at Henkel, “mechanical performance and process. This leaf spring must be very tough and have the durability to withstand hundreds of thousands of dynamic loads under varying conditions. However, the large production volume requires very fast injection and cure.” He sees polyurethane as ideal for this application. “It has a very rigid and dense network, similar to epoxy, which provides high strength,” Kerstan explains, “but it also has a secondary network structure, which gives high elongation and toughness. Both were key for this application.”

“There are numerous resin suppliers out there, offering epoxy, vinyl ester and polyurethane,” notes Fetscher. “However, for our specific project, Henkel was able to best meet the cycle time and cost structure at this high rate of industrialization.”

Kerstan explains that because the glass fiber content in the final part is relatively high, at 55%, “the trick is to inject very fast, but also in a way that does not cause fiber displacement and yet is reliable, part after part.” The viscosity of the LOCTITE MAX 2 resin at room temperature is 200-300 mPa or cps (millipascal-second and centipoise units are equivalent), but at 90°C it drops to 10 cps. “This allows reliable, fast impregnation of the fibers without moving them,” says Kerstan.

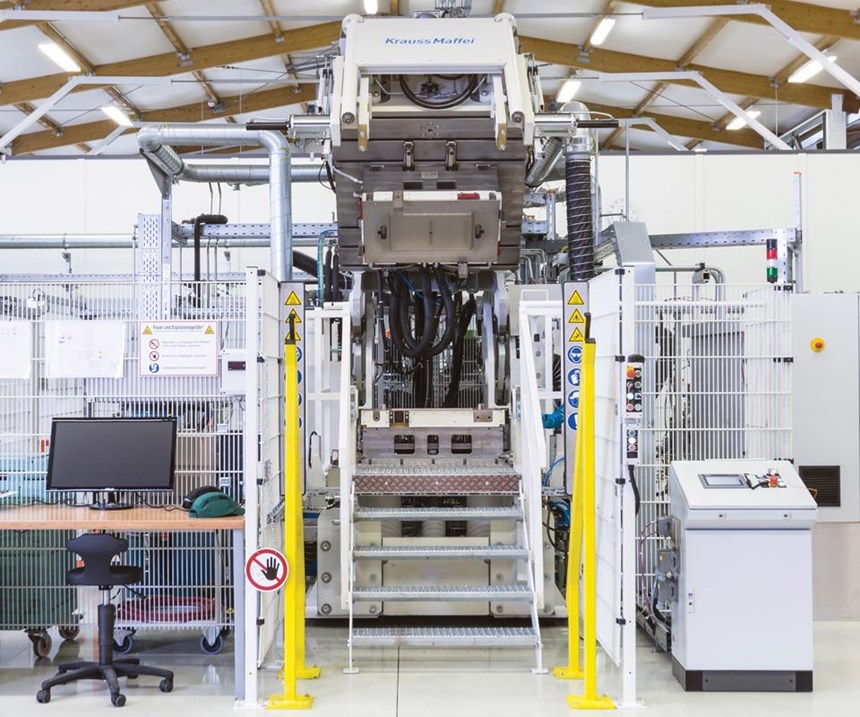

BENTELER-SGL uses a variety of equipment in its Ort im Innkreis facility, including a Streamline machine from Hennecke Inc. (Sankt Augustin, Germany) equipped with a custom mixhead, a KraussMaffei Technologies GmbH (Munich, Germany) mixing and metering unit, a Dieffenbacher (Eppingen, Germany) press for HP-RTM, and a Cannon Afros custom-designed dosing unit for HP-RTM with two specialized FPL14 mixing heads.

For the Volvo leaf spring, the main components of the PU resin are degassed to avoid formation of air bubbles in parts, recirculated in heated enclosures and maintained at temperature through heated piping before they are metered into the two mixing/injection heads. The pressure in the mixing heads is 120-140 bar, and each can inject 11 kg of resin in 22 seconds.

Typical of most high-end meter/mix/dispense machines (see Meter/mix/dispense machines: Doubling down on control), each component’s output is continuously monitored by mass flowmeters, with data fed into the control system. Should a deviation from specified values be detected, the system immediately manages the parameters of the relevant dosing pump to restore the desired output in real time. A 90m2 area was designed to house the various resin component storage, conditioning and pumping devices.

Limiting mold cycle time

Just as heating the resin is necessary to optimize flow and impregnation of the preform, a heated tool is key to curing the composite. So is a multi-cavity tool configuration. Although previous reports have cited 8-10 or even 12 cavities, the actual number used, says Ernst-Siebert, depends on the volume rate of the program. “This can change, depending upon what the customer needs and the part design,” he says, adding, “To meet the customer’s required cycle times, we use a multi-cavity tool, with molding completed in 10 minutes.” Although this does not include preform insertion or part extraction, both operations are automated and designed to meet part volume requirements.

In order to accommodate the three variations in spring curvature, three different upper molds were developed. Three lower molds were developed for each upper mold, enabling varying spring thickness. Thus, nine different bottom molds may be used in production as dictated, eventually, by the mix of incoming model orders. There also are additive options. Kerstan explains that with the LOCTITE MAX polyurethane systems, catalyst can be added to further reduce curing time, depending on part size. He also notes that external or internal mold release can be used. “Whether or not you use external or internal mold release depends on the cycle time and downtime in your parts program and process,” he explains. However, he cautions that because the leaf spring is a dynamically loaded part, and internal release agents can affect part properties, “it is very important that auxiliary products, such as binders, catalyst and internal release agents, match the resin chemistry.” Kerstan also notes that the shape of the tool is a critical factor in defining the best mold release approach: “If it has undercuts and difficult release angles, then external mold release may be required.”

Two new presses are used in the fully automated production lines for the Volvo leaf springs. “We’ve set up a second automated line to reach the peak volume,” reports Ernst-Siebert. Because of the high degree of automation, he points out that only a few technicians are required to operate the lines. “We currently run two shifts, and can run three if needed,” Ernst-Siebert relates. “We are very flexible in order to meet our customers’ demands. We can run these lines 24/7, if necessary.”

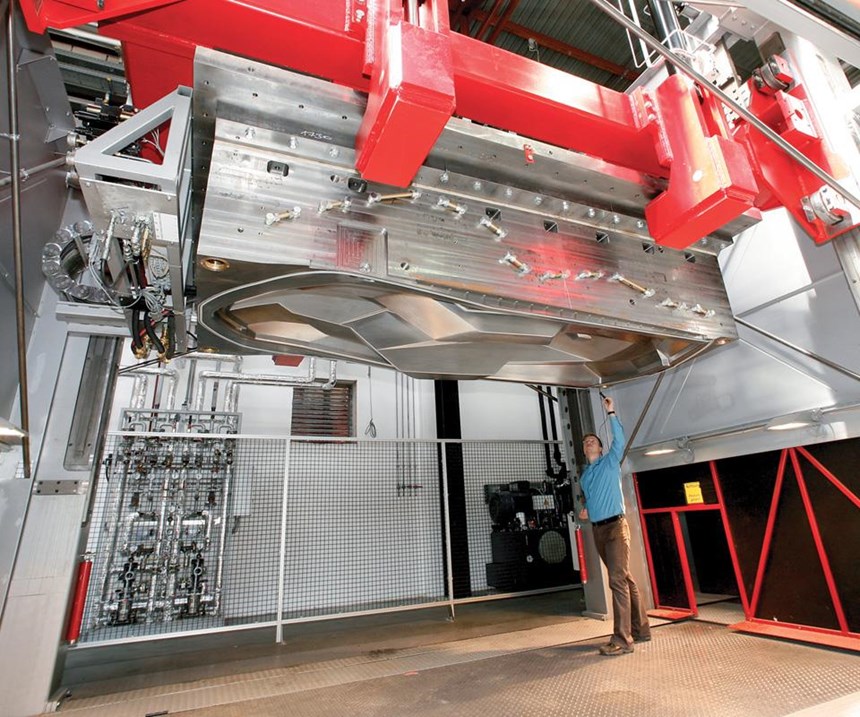

The production presses are comparable to the twin-shuttle 1,600-ton press used in BENTELER-SGL’s R&D center in Ried im Innkreis. Ernst-Siebert stresses the importance of the relationship between this “tech center” and the Ort im Innkreis production floor, “We have an automated pilot line in the tech center that is small-scale yet can simulate the full process. As we set this up in the prototyping phase, we tried to get very close to how we would actually make the parts in production.” He adds that the team also receives simulations of machinery concepts from BENTELER, and material analyses and simulations via SGL’s experts. “This is how we further enhance our processes to move quickly through the HP-RTM development.”

“We also apply this to the dosing unit and injection of the resin,” says Fetscher. “Early involvement of resin partners like Henkel is key in order to identify issues and make improvements early in the process development.”

Ernst-Siebert agrees. “This is important because the process is too complex to adjust just one thing to achieve each necessary improvement — you have to adjust several parameters at a time.”

After the parts have completely cured, they are robotically transferred from the HP-RTM presses to automated milling cells, where they are trimmed and holes are drilled in the ends of each spring. Fetscher considers this automation as standard in the industry, but notes that BENTELER-SGL’s fixture is special and its trim process has no manual steps.

Future developments

With the Volvo rear leaf spring program on schedule to meet peak volume in 2018, BENTELER-SGL is already setting its sights on more. “We have identified other rear leaf spring opportunities and are working to develop further applications with OEMs,” says Fetscher. “The motivation and market drivers remain the same and future alternative vehicle architectures might offer further potential for this kind of application.”

Kerstan agrees, “Other vehicle makers have indicated their intention to adopt this same, lightweight composite leaf spring concept. I am also convinced that the compactness of this leaf spring axle design is a good fit for electric vehicle body/chassis concepts.”

Further, BENTELER-SGL has transferred its transverse leaf spring design and production know-how into applications for longitudinal glass fiber-reinforced springs.

“The replacement of steel leaf springs with composites to maintain the same or even slightly improved function offers a great potential for weight reduction at a reasonable cost per saved kilogram of mass,” Ernst-Siebert explains.

For its part, Henkel is targeting numerous other automotive applications, including structural bodycomponents and exterior paintable parts, such as roofs using Surface RTM (see HP-RTM on the rise). It has also developed a suitable high-temperature (Tg>200°C) epoxy resin system for high-volume production of carbon fiber-reinforced wheels.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More