Composite Rebar Speeds Tunneling Operations

Pultruded replacement for steel reinforcement in concrete clears path for more efficient use of boring machinery.

As mass transit needs grow worldwide, busy, crowded cities are building or expanding subsurface rail systems — called "subways" in the U.S. and "the Underground" or simply "the Metro" in much of Europe. While underground train stations must be built in excavated pits, construction crews minimize excavation and resulting disruption of motorized and pedestrian traffic between stations by cutting train tunnels with huge tunnel boring machines (TBMs).

Because pit floors often fall far below the water table in unstable soils, deep trenches are cut around the station perimeter, and thick, reinforced concrete diaphragm walls are poured to prevent groundwater infiltration and cave-ins. Only then can a dry pit be excavated. TBMs, however, cannot cut the steel rebar used to reinforce the concrete. Until recently, therefore, the portions of station walls where tunnels begin and end had to be removed in a primarily manual operation, before boring could begin. Moreover, to prevent water ingress and/or soil collapse due to water pressure while concrete and rebar were hand cut, crews often first injected and compacted stable soil or even poured a second, unreinforced concrete wall outside the diaphragm wall. These procedures were extremely labor intensive and delayed tunnel-boring operations.

To prevent such delays when construction began in 2002 on a new 9.8 km/6-mile line for its Metro system in Amsterdam, The Netherlands, the Amsterdam Public Transport Authority contracted with reinforced concrete specialist Schöck Bauteile GmbH (Baden-Baden, Germany), the developer of a glass fiber-reinforced polymer (GFRP) rebar product bearing the trademark ComBAR. Used in place of steel rebar, ComBAR cuts easily, permitting the boring machine to penetrate a station wall, cut a tunnel and bore through the wall in the next station down the line in a continuous process, eliminating much of the delay. In addition, this continuous process yields a cost savings even though the cost of the ComBAR is higher than conventional steel rebar.

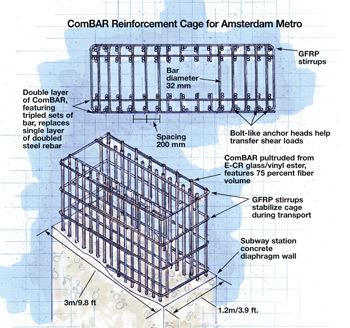

Scheduled to enter service in 2011, the north-south route will run on the surface through the two stations on the north end, then descend underground for 6 km/3.7 miles, connecting with five subsurface stations (Centraal Station, Rokin, Vijzelgracht, Ceintuurbaan and RAI/Europaplein) before leaving the tunnel and entering the line's southern terminus at the Zuid Station. In all, 12 holes needed to be bored through six diaphragm walls to connect the two rail lines that will enter and leave Rokin, Vijzelgracht and Ceintuurbaan. Walls for the underground stations are 1.2m/3.9 ft thick, and are poured in individual sections 3m/9.8 ft wide by pit depth. Each section requires a prefabricated rebar "cage" approximately 0.2m/0.66 ft narrower in both dimensions. Schöck planned to fabricate 24 cage sections made of ComBAR (two per bore) and insert them into the steel rebar scheme where tunnel openings were to be located. Overall, more than 176,370 lb (80 metric tonnes) of ComBAR will be used.

BUILDING THE BASIC BAR

ComBAR rebar is pultruded by Fiberline Composites A/S (Kolding, Denmark), using unidirectional E-CR glass fibers in a specially formulated vinyl ester hybrid resin matrix that protects the glass fiber from corrosion in the aggressively alkaline concrete environment. Fiber wetout is controlled using high-pressure injection impregnation, and the design results in a very high fiber content of 75 percent by volume. The fiber's axial orientation optimizes the axial tensile load-bearing capability of the rebar, a critical performance parameter. Andre Weber, Schöck's director for research and development for FRP, explains that while concrete alone shows sufficient compressive strength — in the range of 3,000 psi to 8,000 psi (20.6 MPa to 55.1 MPa) — it exhibits a tensile strength in the range of 5 to 10 percent of its compressive strength. Steel rebar, with strength up to 72,500 psi (500 MPa) compensates for this weakness, enabling reinforced concrete to better withstand not only compressive loads, but also bending, shear, and tensile loads. Lab tests on ComBAR resulted in failure in tensile with a mean value of 174,000 psi (1,200 MPa), more than twice that of steel rebar.

Weber points out that the key to any concrete structure reinforced with rebar is the bond between the rebar and the concrete. If cracking develops, then the potential for surface damage to GFRP rebar can result in the rebar being compromised, thus increasing the likelihood of failure. Testing has shown that the failure mechanism for ComBAR reinforced structures is shear failure of the concrete, the same as with steel rebar, with ultimate loads depending on the strength of the concrete. When tested, the slip — the amount the rebar moves in relation to the concrete — is measured up to the point of bond failure. This slip and the applied load are then used to calculate the crack width and the crack distance. "The ductility of the bond failure is a critical issue regarding safety considerations," explains Weber. "The stress-slip relationship has to show enough bond energy to ensure a bond sufficient to prevent progressive pullout failure when the maximum load is applied."

To optimize the concrete/ComBAR bond, a helical pattern (similar to that in steel rebar) is machined into the cured bars to increase the bonding surface area and create a mechanical lock with the cured concrete. This secondary threading operation uses a specially shaped grinding blade to cut away material as the bar is rotated. A thin coat of resin is applied and cured to cover the fibers exposed during machining. Rebar that must be bent is pultruded with a slightly higher resin content and exits the pultrusion die before it's fully cured. The helical pattern is machined and the bar is bent to the desired shape, and then fully cured.

Due to the depth of the Amsterdam Metro line, shear forces up to 2000 kN/m had to be transmitted. With steel rebar, the need for a high level of shear reinforcement results in a very complicated cage structure, which makes it difficult to pour the concrete. To help transfer shear loads, Schöck designed a version of ComBAR that uses a bolt-like anchor head at each end of the rebar. Anchor heads are an injection molded, high-temperature, alkali-resistant, glass-reinforced thermoplastic and are molded directly onto the ends of a straight section of ComBAR. The heads reduce slip and increase the total stiffness of the shear reinforcement compared to stirrups. (Stirrups are an approximately 90° bend at the end of a piece of steel rebar to prevent slipping between the rebar and concrete when loaded.) The heads are designed using a strain limit to ensure the same failure mode and factor of safety as steel rebar. This innovation enabled ComBAR to match the shear properties of the steel while reducing cage complexity, thus simplifying the concrete pour.

CAGE CONSTRUCTION

For the Amsterdam Metro project, both steel and ComBAR cages are assembled offsite and then trucked to the construction site. While steel rebar cages are welded, the ComBAR bars are combined into cages using conventional tying wire and horizontal, wraparound "stirrups" made of the higher-resin-content bent sections of ComBAR (see drawing on p. 44). (It must be noted that these stirrups do not have the same function as steel rebar stirrups. Rather, the ComBAR stirrups simply help to stabilize the cage as it is being transported to the construction site. Once the concrete is poured, the ComBAR stirrups no longer have any structural function.)

To conform to standard cage design practice, Schöck had to account for several differences between steel and ComBAR in terms of performance. While long-term deflection and creep in ComBAR-reinforced wall sections are comparable to that occurring in steel-reinforced wall sections, ComBAR's lower modulus of elasticity requires special attention to control deflection and crack width. Because tunnels are as much as 28m/92 ft below the ground water level, loads are very high on the tunnel side and generally nil on the station side, so inward bending of the walls had to be considered. Recommended design parameters include a maximum allowable tensile stress of 250 MPa (3,620 psi) and a maximum allowable strain of 0.42 percent, which allow for a reasonable factor of safety. Weber notes that while steel rebar has a modulus of 200 GPa (29,000 ksi), the first generation of glass rebars, developed in the 1990s, showed a modulus of around 40 GPa (5,800 ksi) and ComBAR shows a modulus of 60 GPa (8,700 ksi). If GFRP rebar replaces steel, piece for piece, the resulting greater wall deflection will result in greater crack width and depth, causing, in turn, higher residual loads in the uncracked concrete. This increases the compressive load on the concrete, which is a limiting factor in most design cases, according to Weber. To compensate for the shortfall, the density of GFRP rebar per unit area must be greater. In the most highly loaded sections of the Amsterdam diaphragm walls, where a single layer of doubled 50-mm/2-inch diameter pieces of steel rebar would be placed at intervals behind each wall face, Schöck substitutes in the bore area two layers of tripled 32-mm/1.25-inch ComBAR at the same spacing.

CAGE LOCATION

At the job site, steel and ComBAR cages are connected using standard fish plates (steel plates affixed to each cage) commonly used when joining separate sections of steel rebar cage prior to casting. When wall trenches are excavated, the first steel cage is lowered part way into the trench and suspended to allow attachment of the middle ComBAR cage, at the point in the wall where the tunnel will be bored. The sections are threaded together until their fish plates align. The plates are secured with conventional steel bolts. The two sections are then lowered into the trench and suspended to permit similar attachment of the top steel cage. When the reinforcement cages are completely connected, the concrete diaphragm is cast.

Because the TBM can cut directly through the ComBAR-reinforced wall, soil stabilization and secondary concrete walls are no longer necessary, and relatively simple waterproofing strategies can be employed inside the pit to keep it dry during the boring process, according to Schöck.

MORE THAN BORING

While its cuttability was its most desirable feature in Amsterdam, Weber points out that ComBAR is a better option than steel for concrete reinforcement in many highly corrosive environments. In bridges and parking structures, for instance, exposure to chloride ion sources, such as road de-icing salts, can rapidly corrode steel rebar, rendering the concrete vulnerable to tension and bending loads. Additionally, ComBAR is finding application in surface railways in the cities of Delft and Magdeburg, where its electromagnetic transparency eliminates rebar interference with track switching signals and other electrical functions in concrete track beds.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More