Aerospace-grade compression molding

Continuous Compression Molding process produces structures 30 percent lighter than aluminum at costs that have both Airbus and Boeing sold.

In the drive to lightweight commercial aircraft, a recently opened frontier is the production of interior aircraft brackets, many in the form of lengthy formed profiles. These critical but often unseen aircraft assembly components — C-channels, H-beams, U-sections, L- and T-stringers and hollow trapezoidal/hat stringers — have long been produced in aluminum. Compression molding, a process more commonly associated with automotive and industrial composites, is changing that. Continuous Compression Molding (CCM), an automated, semicontinuous manufacturing process, has the capacity to take reinforced thermoformable input (for input types, click on the sidebar link at the end of this article) and produce highly shaped profiles or flat panels of effectively unlimited length. Operable by one person, the computer-controlled process yields product at speeds approaching those quoted for pultrusion — as high as 40m/hr (131 ft/hr) for shaped profiles and up to 91m/hr (300 ft/hr) for flat panels.

Unlike thermoplastic pultrusion, in which thermoplastic resin is injected into dry fibers at the die, CCM uses input materials akin to aerospace-grade epoxy prepregs — highly aligned, continuous fiber reinforcements preimpregnated with high-end thermoplastics, including polyetheretherketone (PEEK), polyetherketoneketone (PEKK), polyetherimide (PEI) and polyphenylene sulfide (PPS). For nonaerospace applications, polypropylene (PP) and other engineered plastics are the common matrices. The resulting thermoplastic structures exhibit aerospace-quality consolidation. The void content is routinely less than 1 percent (verified by laminate micrographs), compared to the typical requirement of less than 2 percent for autoclaved composites. Commercial products, to date, have used carbon or glass fiber (although they can be made with aramid or other fibers) and include highly loaded structural elements, such as the carbon fiber/polyetherimide (C/PEI) fixation rail assembly used to attach Airbus A330/A340 interior sidewall panels. According to CCM manufacturer Xperion Aerospace GmbH (Herford, Germany), more than 30,000 such rails have been produced, replacing aluminum with an almost 50 percent weight reduction and lowering production cost by 21 percent, after two years, with a part rejection rate of less than 0.1 percent.

A history of knowledge and experience

CCM isn’t new. Ulrich Spelz, a thermoplastic composite (TPC) pioneer in the early 1990s at aircraft manufacturer Dornier (Wessling, Germany), developed and patented CCM. In 1999, he founded Advanced Composites and Machines GmbH (ACM, Markdorf, Germany) to advance the process, test new TPCs, prototype tooling for customers and bring parts to serial production. An early success was the spring for Bico AG’s (Schänis, Switzerland) innovative slatted bed design, nominated for a JEC award in 2002 (see third photo down, at right). ACM worked with Dyne Design Engineering (Niederlenz, Switzerland) and manufacturer Nägeli Swiss AG (Güttingen, Switzerland) to adapt the spring design for Spelz’s process. The resulting CCM machinery took in five plies of Gurit (Isle of Wight, U.K.) Plytron 60-percent glass-reinforced PP unidirectional (UD) prepreg tape and then heated and compressed the material. The resulting consolidated sheet was automatically cut into 650-mm by 200-mm (25.6-inch by 7.9-inch) plates. These were fed into a two-sided hydraulic stamp-forming press, which heated them to the forming temperature and, every 50 seconds, stamped 25 springs, each 25 mm wide, roughly 70 mm in length and 1.4 mm thick (0.98 inch by 2.75 mm by 0.06 mm). The process produced 1.4 million parts per year, through 2007.

In 2004, ACM was approached by Boeing Phantom Works (St. Louis, Mo.) to assist in developing thermoplastic composite parts for future aircraft, such as the 787 Dreamliner. Plans included a CCM machine capable of producing both panels and shaped profiles for use as a research platform in its St. Louis facility. This prompted ACM to seek an alliance with a larger manufacturer that could shoulder the significant investment. Spelz had crossed paths with Xperion previously, when the company was founded in 2000 after purchasing parts of Dornier. Xperion acquired ACM on Jan. 1, 2007, and Spelz remains Xperion’s chief technology manager.

Xperion delivered the machine in 2005 and, led by Spelz, continued its work with Boeing, prototyping a variety of thermoplastic composite aircraft parts using CCM. “Boeing wanted more and larger components,” Spelz recalls, “so Xperion began to consider the benefit of having a corporate presence in the U.S.” This led to a 50/50 joint venture with Cutting Dynamics Inc. (CDI, Avon, Ohio), a longtime supplier of machined metal components for Sikorsky (Stratford, Conn.) and a qualified supplier for Boeing and Bell Helicopter (Ft. Worth, Texas). CDI had significant thermoplastic composites experience, having purchased a Fiberforge (Glenwood Springs, Colo.) Relay Station automated tape laying cell, which it used along with a traditional stamp-forming press to produce TPC parts for aircraft seating. The new entity, Xperion/CDI, is headquartered in CDI’s Avon facility and could begin production of thermoplastic composite ceiling parts for the Boeing 787 this year. Parts for Airbus will continue to be sourced from the Xperion Aerospace facility in Germany.

CCM process step by step

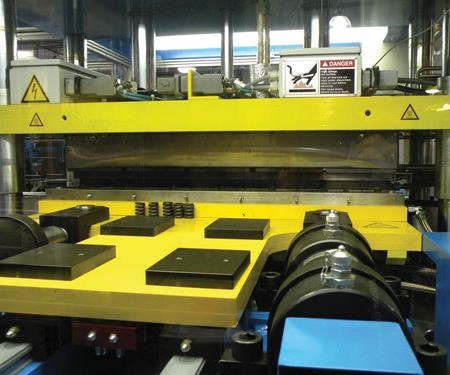

Both the Xperion Aerospace and the Xperion/CDI facilities have flat panel and shaped profile CCM machines. Xperion/CDI has one of each. The flat panel machine is capable of a 1600 kN (~360,000 lbf) compression force across a width of 26 inches (660 mm) and a thickness up to 0.4 inches (10 mm) at a maximum feed rate of 300 ft/hr (90m/hr) and a maximum press temperature of 770°F (410°C). The shaped profile machine can apply a 400 kN (~90,000 lbf) force over a 4-inch by 4-inch (100-mm by 100-mm) area at a maximum rate of 150 ft/hr (30m/hr), with the same thickness and temperature capability as the panel line.

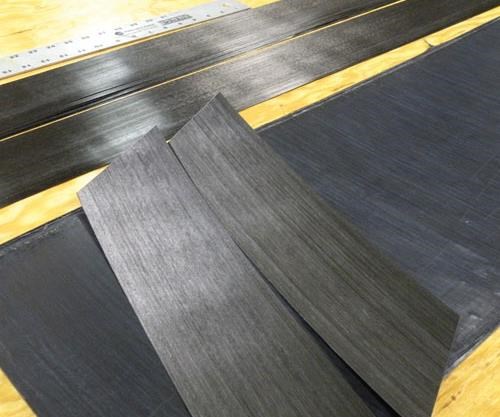

The CCM process on the panel line begins with the feed creel, which is loaded with as many rolls of semifinished TPC input material as are required to form the specified laminate schedule. If the laminate requires angled plies that are not readily spooled, then strips of woven or UD input material may be cut and butt-welded edge-to-edge or tacked together to form a multilayer panel of a specified stacking sequence. This welded laminate is then loaded onto the feed creel. According to Xperion/CDI, tack- or butt-welding is a simple process that also may be automated. But typically, the input material for the shaped-profile line is UD tapes, with no additional preparation required other than loading the spools onto the creel.

On both lines, a hydraulic feed mechanism pulls the input material into the heating area. It is compressed between two stainless steel belts on the panel line. On the profile line, UD input is shaped by stainless steel “preformers” prior to entry into the shaped die (for the latter, see Shaped Profile Line Step 2, at right). On each line, the material is brought up to flow temperature and then pulled into a compression molding press, which features either two flat steel plates, for panels, or steel dies for shaped profiles. The continuous consolidated sheet or shaped profile exits the press area and is automatically cut and stacked or wound onto a spool.

Fully computerized, each line may include automated inline quality assessment. Xperion/CDI’s flat panel line already uses a system of four linear encoders to continuously measure panel position and compute panel thickness and laminate consolidation as it exits the press. All data is recorded and can be monitored and analyzed to ensure conformity to specifications. The data record is sufficient to support FAA-required paper trails. The same system can be installed on the shaped profile machine as well. Some CCM systems also incorporate inline C-scan equipment.

Inherent process flexibility

CCM was developed using C/PEEK materials, specifically APC-2 products from Cytec Engineered Materials (Tempe, Ariz.). Work with less challenging PP, PEI, PPS and other thermoplastics followed. “We assumed that if we could process high-temperature thermoplastics, then we could solve most of the problems with low-temperature thermoplastics,” says Spelz. All of these input materials work well with CCM, so that material selection is based on specific customer needs. But some materials reduce the processing speed. UD prepregs, such as C/PEEK or C/PEKK from Cytec or C/PPS from TenCate (Nijverdal, The Netherlands and Morgan Hill, Calif.) and fabric prepregs, such as TenCate’s C/PEI, process simply, he maintains, but “film-stacked or powder-coated materials need longer impregnation of the fibers after reaching flow temperature during consolidation, and therefore, the machine speed must be lower than when using well-impregnated materials.”

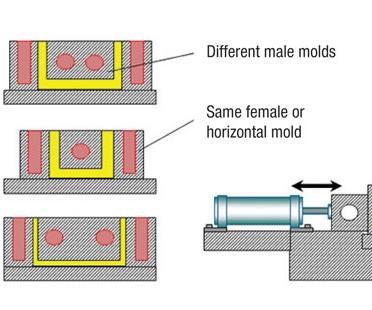

CCM tooling has benefited from extensive development. “A lot of suppliers working on thermoplastic composites came from the injection molding industry or from a background of deep-draw-forming automotive components, where tooling is quite complex and expensive,” Spelz notes. “At Xperion, we developed a new tooling system, based on quick-change modules.” All CCM tooling is adapted for a standard pattern of mounting holes on the machine and are designed to be modular. Several types of shapes can be created with one tooling set, and all the different male and female tools can be combined and are easy to change out and modify. For example, an L-shaped female tool can be used with different male tools to achieve different thicknesses or outer radii (as long as the dimension of the component legs are the same) without designing new sealing pieces or heating devices. Spelz says modular tooling has saved money and time, especially during prototyping.

CCM’s flexibility is enhanced by the fact that the part layup can be altered by adding layers and/or changing the stacking sequence without stopping the machine, simply by adding, removing and/or replacing spools onto the feed creel and introducing them into the feed at the appropriate location in the stack. Spelz illustrates this benefit: “For long rails, thickness can be increased in high-load areas.” The CCM process may be modified for constant high-speed production of smaller and thinner parts.

“Because CCM allows you to change each of the variables independently,” notes Xperion/CDI managing director Bill Carson, “the process is very amenable to prototyping and reaching a solution quickly.” Carson also notes that the shaped profile machine’s ability to apply both vertical and horizontal force to produce shaped profiles (see illustration on p. 38) results in very high-quality composites with no wrinkling, even on complicated geometries. “This is not easily achieved with traditional vacuum bagging,” he notes. Carson also sees flexibility in the recyclability of TPCs.

Present limits, future promise

Xperion/CDI’s first products will be ceiling components for the 787, including C-shapes and L-shapes, approximately 2-inches/51-mm wide, that will carry all loads for the overhead bins. Although the sidewall rails for Airbus were made with TenCate C/PEI fabric prepreg, the 787 parts will, most likely use C/PEEK or C/PEKK unidirectional tapes.

“We have prototyped interior sidewall panels using CCM panels,” says Spelz, “but the materials are too expensive for such a large part vs. the current phenolic materials, which are very cheap.” Additionally, the very large machines necessary for sidewalls are less conducive to CCM processing. “Behind the interior sidewall panels are many smaller parts well-suited for thermoplastic composites and CCM.”

“We take the view that you have to be honest about what material and process will function best to produce a given part,” says Spelz. He readily admits that not every part is best produced using thermoplastic composites and that hollow parts and sandwich constructions are better suited to thermoset processing.

At the Institut für Verbundwerkstoffe GmbH (IVW, Kaiserslautern, Germany), however, there have been recent breakthroughs into sandwich construction and hollow shapes. In 2009, the nonprofit research body demonstrated the continuous manufacture of hollow profiles via CCM by employing a modified design that incorporates a floating core in the center of the tooling. Continuous-length parts were made with a variety of layups, showing good consolidation and fiber volumes between 55 and 60 percent. The work also explored processing with polybutylene terephthalate (PBT), formed during processing from the reactive monomer cyclic butylene terephthalate (CBT), supplied by Cyclics Corp. (Schenectady, N.Y.). Cyclics’ formulation process breaks PBT down into a cyclic oligomer form that, when heated to a specified temperature, drops to a water-like viscosity, facilitating fiber wetout. Catalyzed and then cooled, the oligomer returns to more conventional viscosity and forms the long-chain, high-molecular-weight PBT thermoplastic. According to Cyclics, the material offers the properties of a thermoplastic but can be processed like a thermoset. To visualize the benefit, says Steve Winckler, a key patent author for CBT, one must “think melt viscosity of cream for CBT vs. silly putty for PBT, properties much closer to epoxy than polypropylene, at a neat resin cost of $6/lb to $8/lb — only slightly higher than PEI ($5/lb to $6/lb) and a fraction of PEEK and PEKK ($30/lb).” Winckler also explains that, as a matrix, CBT inherently “wants” to impregnate composite reinforcements, resulting in much better resin-to-fiber distribution, which also helps to achieve mechanical properties closer to those of epoxy prepreg vs. traditional thermoplastics. IVW reports that use of CBT increased processing speed by a factor of 10 — dramatically reducing production costs — with no loss of mechanical properties.

Spelz and Carson agree that the next step is to combine the high mechanical properties (traditionally achievable only with thermoset composites) with the high speed, high quality and low cost of CCM to produce, first, stringers and stiffeners for aircraft ceilings and structural components, and, eventually, skin-stringer assemblies, well-aimed at applications such as flooring. CCM profiles and CCM flat sheets can be fusion-bonded to produce very long assemblies, quickly and cost-effectively. Here, Carson sees a whole new world open to Xperion/CDI. “Based on CDI’s long history as a supplier, we know the material and labor costs of aerospace parts,” he notes. “We now have a process which is easily adapted to take advantage of the opportunities we see, We can replace aluminum and other metal structures with composites that are at least 30 percent lighter but at a cost previously unattainable, and we can readily recycle.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More