Share

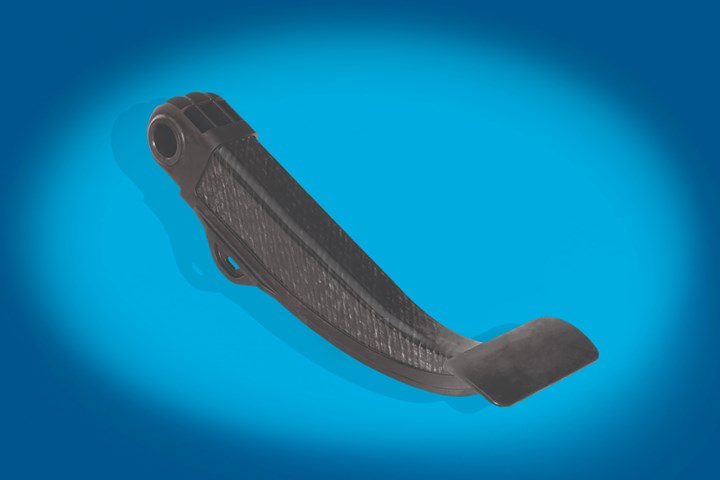

The first all-composite brake pedals developed by Boge Rubber & Plastics Group using a bespoke production process meet or exceed the challenging performance specs required of metals at nearly half the weight. Photo Credit: Boge Rubber & Plastics Group

Tier 1 Boge Rubber & Plastics Group (Damme, Germany) produces what it says are the lightest, least costly and strongest all-composite brake pedals in the world, and the first in commercial production. As detailed in the January FOD (see “Thermoplastic composite structure replaces metals on safety-critical brake pedals”) the supplier currently produces a quarter-million brake pedals per year for four vehicle platforms produced by German automakers and the system could produce up to 1 million pedals annually. This is significant because the pedals are structural, are required to meet the same rigorous performance requirements as incumbent steel and aluminum, and the designs feature three different types of glass-reinforced thermoplastic composites.

Three materials increase fiber efficiency

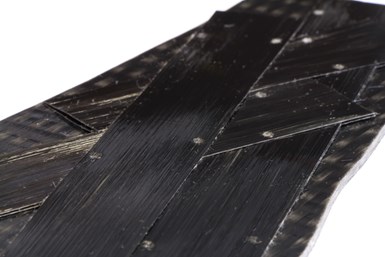

To keep pedals light, thin, cost-effective and capable of meeting challenging OEM specs, Boge uses continuous glass fiber organosheet as the shell structure to carry the part’s main loads, which can be as high as 3,000 newtons. Organosheet blanks are supplied precut to size, with two or three layers fully consolidated by supplier Lanxess Deutschland GmbH (Cologne, Germany). To reinforce the main load paths on the organosheet blank, Boge adds strips of unidirectional (UD) glass fiber tapes (supplied by Celanese Corp., Irving, Texas, U.S.) in orientations and layups based on finite-element simulation results. To do this, Boge uses software it has modified and material cards the company has developed with its suppliers based on stress/strain curves measured for each material under temperature and humidity conditions specified by OEM customers. To add functional geometry, Boge uses overmolded chopped glass fiber compounds (from multiple suppliers) to provide structural ribs and attachment features.

All materials feature matrices of precolored black polyamide 6 (PA6), a tough polymer widely used in the automotive industry. Should OEM specs require such, Boge also has the option to use a higher temperature, less hygroscopic PA6/6 matrix in the overmolding compound, since both polymers are similar enough to bond to each other. By using three different types of composites with glass reinforcement in three different forms, Boge is able to place fiber precisely where needed to meet performance requirements while avoiding over-engineering. The carry-on effect of this hybrid-composite approach is that it reduces material usage, nominal wall thickness, cycle time and overall part cost.

Part of Boge’s bespoke production process for producing all-composite brake pedals in three different materials. Photo Credit: Boge Rubber & Plastics Group

Process steps and equipment criteria

Partnering with automation/assembly line developer M.A.i. GmbH & Co. KG (Kronach, Germany), Boge has developed a three-step production process that is fast, efficient and produces quality-verified parts at affordable costs. In designing process and equipment, the team had a number of requirements. First, to keep part costs low, the companies needed to keep total effective cycle time at ~1 minute. Achieving this would require automation to ensure materials moved smoothly through the manufacturing cell.

Second, while the organosheet blanks are supplied prestacked, fully consolidated and precut to size (contoured), the requirements of various pedal designs meant the team needed flexibility to cut, orient and place tape strips of different lengths in different locations and directions to reinforce the main load paths of the organosheet shell. Again, to keep costs down, a bespoke tape-laying process was designed to offer a high level of flexibility and control, as well as speed.

Precut and prechecked unidirectional tapes are precisely positioned at strategic locations on the organosheet to reinforce load paths on the part’s shell structure. To keep tapes from shifting during subsequent steps, they are tacked (via laser spot welding) to the surface below. Photo Credit: Boge Rubber & Plastics Group

At the start of the process, the manufacturing cell holds two stacks of precut organosheet blanks in cassettes and four creels of UD tapes at one time. First, a robot picks up a contoured blank of organosheet and moves it to the work surface. At the same time, UD tape is fed out and cut to the required length. Strips are then placed on a vacuum belt that holds them in place as the conveyor advances. Next, a robot with a revolving pick-and-place unit (end effector) plucks one strip at a time from the vacuum belt and a camera checks each strip for quality, dimension and position. When all four pieces have been picked up, the robot moves to the workspace and begins placing one strip at a time on the organosheet blank in the location and position determined by image-based position correction. As each strip is positioned, it is prevented from shifting by multiple spot welds created by a laser. Meanwhile, more tape strips are being cut and placed on the vacuum belt and the process repeats until all tapes required for a given brake pedal design are stacked and tacked in the correct position on the organosheet.

The system that produces this tailored-fiber blank is 100% numerically controlled, with every aspect of the operation fully programmable for maximum flexibility. At each step, cameras or other sensors, which are connected to the system’s online quality control (QC) system, detect all edges and positions of tape strips and the organosheet shell and compare geometrical data for these materials against known parameters to assure each material is positioned where it needs to be.

To keep production speeds high, the tailored-fiber blank next moves to an infrared oven to heat both materials just prior to draping/preforming/consolidating tapes onto the organosheet. A special antioxidant package in tape and organosheet resin systems prevents thermal damage. Next, the hot blank is quickly moved into the draping/preforming cavity where high pressure is used to form the blank into a U-channel shape while assuring a high-quality surface. The QC system again monitors consolidation and preforming quality via time, temperature and pressure.

Boge’s process produces parts with multiple thicknesses, but roughly constant fiber-volume fraction in the shell structure. Shown above, UD tapes (orange circles) can be seen consolidated into the organosheet shell after preheating/consolidation/preforming but before overmolding. Photo Credit: Boge Rubber & Plastics Group

Finally, the still warm and draped perform is shuttled into an injection mold where it is overmolded with a short-glass/PA compound to create additional geometry such as a complex rib structure on the underside. After demolding, a quick, automated trim and visual inspection are done. No paint or other surface finishing is needed. Final pedal size is approximately 350 x 90 x 60 millimeters. Before leaving the manufacturing cell, a unique QR code is affixed to each pedal to link it back to the manufacturing and materials data for that pedal in the quality system. After assembly, a functional test of the pedal within its bracket and a final robotic inspection are performed. Assuming the unit passes, another QR code is affixed to the completed brake pedal assembly to provide complete traceability of each pedal and additional components prior to shipment to the OEM.

Because brake pedals are safety-critical parts and must meet demanding OEM performance as well as quality requirements, Boge and its partners have built multiple failsafe mechanisms into the Industry 4.0-compliant QC system to quickly and accurately verify that specifications were met at each step in the process. QC data are stored and each pedal receives a unique identification number in the form of a QR code to assure 100% traceability of material, shifts, and process conditions involved in producing that part.

The all-composite brake pedals Boge is producing are roughly half the weight of pedals in metal. They also improve driving haptics for consumers, are 100% recyclable at end of life and meet or exceed the strength requirement for incumbent steel.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)