Big museum, big structures

Massive aramid/carbon composite sandwich panels make Amsterdam’s Stedelijk Museum the largest composite-clad building in the world.

Modern expressions of art have been on display since 1895 in Amsterdam’s Stedelijk Museum of Modern Art. Now the storied museum boasts a stunning and futuristic-looking new entrance and exhibition space that stands as a piece of modern art in its own right. “The Bathtub,” as locals call the addition, stands, or rather floats, in stark contrast to the straight lines and decorative neo-Renaissance style of the original 19th century building to which it is linked.

Designed by architect Mels Crouwel of Amsterdam-based architectural firm Benthem-Crouwel (BCA), the 3000m2 (32,292-ft2) structure boasts a completed façade with a shining white surface that is smooth and seamless — much like the common bathroom fixture that inspired its nickname. But this structure, the world’s largest composite-clad building, is anything but ordinary. “Crouwel knew that if he designed a new entrance that looked like the old building, no matter what he did, visitors would always be able to tell that one side was old and one was new,” says Danny Wilms Floet, sales and technical manager for composites at Teijin Armaid BV (Arnhem, The Netherlands), a subsidiary of Teijin (Tokyo, Japan). Because Teijin Aramid’s headquarters is in The Netherlands, Teijin became a primary sponsor of the museum’s renovation project. Rather than fight the old/new dichotomy, the architect embraced it, juxtaposing the old brickwork of the original building with the extension’s new high-gloss, seamless façade.

Critical to the architect’s vision was the seamless effect on the building’s exterior. However, creating a seamless wall that measures 100m/328-ft long is no small feat. “The architect had the idea, but, in the early phase, it was unclear how that vision could be turned into reality,” says Wilms Floet.

For the past six years, an array of companies, including Teijin Aramid and Toho Tenax (Wuppertal, Germany), which donated aramid and carbon fiber, respectively; Holland Composites (Lelystad, The Netherlands), the manufacturer of the façade; and engineering firm Solico BV (Oosterhout, The Netherlands) worked in concert to design, engineer, produce and install the panels that make up the new extension’s composite cladding.

Challenge 1: Thermal expansion

The first step in realizing the architect’s vision was to determine what, if any, material could provide the desired super-flat, super-smooth, seamless finish. Most troublesome was the seamless 100m/328-ft wide expanse required on the structure’s largest side. Panels made from conventional construction materials need dilation seams to allow for expansion and contraction caused by changing temperatures. Depending on the material, these seams can be as wide as 20 mm/0.79-inch. And the façade is not only exposed to changing external temperatures (expected to range from -25°C to 35°C/-4°F to 95°F) but it also must withstand large differences between internal and external temperatures.

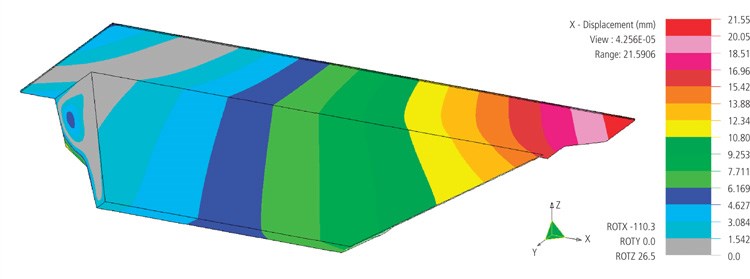

A feasibility study conducted by Solico focused on finding a materials solution that would provide minimal thermal expansion and contraction yet yield enough rigidity to bear high wind loads and other environmental hazards without buckling or warping. Any distortion would be easily visible on such a large, flat, high-gloss surface.

Solico analyzed 3-D digital models supplied by BCA, adding dimensions and properties of the different elements and materials and including static sections to indicate where the façade would be fixed to its supporting steel structure. Simulations were conducted to see how particular composite materials would withstand the stresses and strains of high winds, summer heat and winter frost. In addition, wind tunnel testing was conducted on a physical model of one section of the façade.

The optimum materials solution, according to Solico, needed to meet tight tolerances: To be acceptable, a finished panel would exhibit a deformation level of no greater than 0.3 percent of a panel’s total dimensions and a thermal expansion of no more than 0.1 percent of its total length.

“Every millimeter counts when you need 100m [328 ft] of seamless-looking structure,” says Wilms Floet. “An extension made of glass fiber or aluminum, for example, could result in an expansion of about 17.5 cm [6.89 inches] with a temperature rise from -20°C to 50°C [-4°F to 122°F].”

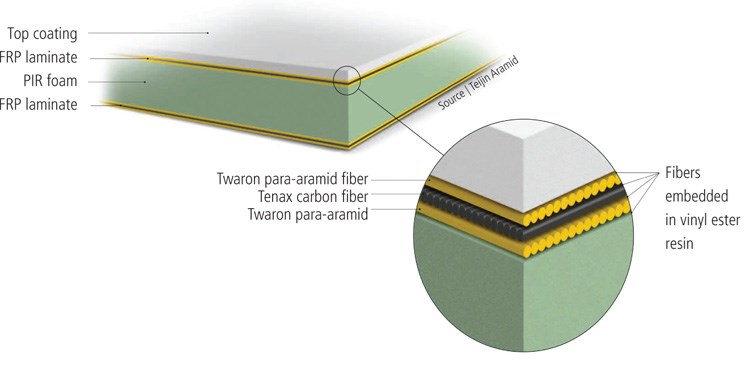

According to Solico’s analysis, a potential materials solution was a composite sandwich construction that incorporated Teijin’ Aramid’s Twaron aramid and Toho’s Tenax carbon fibers wet out with a vinyl ester resin over a polyisocyanurate foam core.

“Using Twaron and Tenax, there is an expansion of 1 mm [0.39 inch] per degree Celsius temperature rise,” says Wilms Floet. The aramid and carbon fibers have a negative longitudinal thermal expansion coefficient, meaning they contract as temperatures rise, while under the same conditions the vinyl ester resin expands. “The fiber, more or less, counteracts the expansion of the resin, resulting in a material with a very low thermal expansion,” he explains.

Teijin produced and donated Twaron aramid fiber and Tenax carbon fiber for the structure, enabling what would otherwise be a cost-prohibitive solution. “Without the Twaron and Tenax fiber, we would never have been able to realize the structure as it is now,” says Wilms Floet. Teijin Aramid’s fiber research laboratory verified Solico’s analysis on actual samples of the proposed sandwich structure. And Holland Composites, tapped to manufacture and install the panels, constructed a prototype consisting of six panels bonded together, sanded and coated, which was used by Holland Composties and Solico to confirm the composite’s ability to provide a flat, smooth surface.

Challenge 2: Large and flat panels

Although the panels were large — the biggest measured 15m high by 3.5m wide (49 ft by 12 ft) — the greatest manufacturing challenge was to achieve the complete flatness required for each panel, says Sven Erik Janssen, co-owner and production manager at Holland Composites. The slightest variation in the flat, high-gloss 100m expanse of the structure would be easily visible.

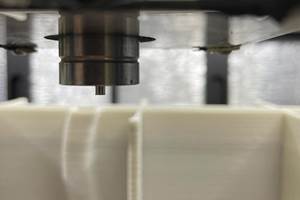

As a solution, Holland Composites constructed a large flat mold using float glass panels. (Float glass is made by, literally, floating molten glass on a bed of molten metal. The result, when cooled, is a plate with uniform thickness and a truly flat surface.) “We’ve used float glass before in the manufacture of flat panels,” explains Janssen. “For this project, however, we applied a self-leveling compound to the glass to ensure a surface that was as flat as it could be.”

The tool measures 17m by 4m (56 ft by 13 ft). In all, Holland Composites produced 275 components to make 185 panels required for the Bathtub’s façade. Each panel was unique. “Panels varied in size,” says Janssen. “Some also required holes to allow for lights and cameras to be mounted into the façade.”

“We have a product traceability system, so all panels have [their] own construction checklist[s] and measurement documentation,” he adds. “Every panel had to be measured onto the flat mold before production could begin and then again during production,” he adds.

Solico provided the calculation for ply layup of the sandwich structure and staging of the fiber. After mold release was applied, the buildup began with E-glass fabric. “Aramid fiber is good at what it does, but the fibers themselves do not completely impregnate with the resin,” says Janssen. “So, the first layers on the outside of the panel are glass fibers, which provides a more resin-rich exterior to support sanding and coating preparation.”

Next, two layers of Twaron para-aramid unidrectional (UD) fabric were applied with a layer of Tenax carbon fiber UD fabric in between, placed perpendicular to the aramid. In total, 4,850 kg/10,692 lb of Twaron high-modulus fiber, with a linear density of 8,050 dtex, and 4,050 kg/8,928 lb of Tenax STS-40 24K fiber were used in the project. The fire-retardant polyisocyanurate foam for the core came from the Recticel Group (Brussels, Belgium).

Lastly, aramid and carbon plies were repeated, and then the panel layup was vacuum bagged for vacuum injection of a fire-retardant vinyl ester resin from DSM Composite Resins AG (Schaffhausen, Switzerland).

“The complete manufacturing of the panels took nearly six months,” says Janssen. “There was a lot of handwork in building the laminate and finishing work after the panels were produced,” he adds. “Some of the finished panels were built by combining multiple panels to create the round corners of the Bathtub, and some panels have round edges mounted on one side for water drainage.” All of the corner elements were bonded at Holland Compositess manufacturing facility prior to shipping the panels to the work site.

Challenge 3: Precise installation

The job didn’t end with the fabrication of the façade panels. The company was also tapped to install the panels and apply the topcoat.

The 23-week installation required several innovative solutions. “Because of the size of the panels, typically 15.0m by 3.5m [49 ft by 12 ft], and other work being done on the site, we had to do most of the installation work on the façade on the weekends or at night,” explains Janssen. Panels were delivered to the site, which sits in a busy area in the center of Amsterdam, during controlled time windows in the early morning. In all, it took six weeks to deliver all of the panels.

Because the final panel assembly was done on site, the massive coating operation was also done on site. Holland Composites constructed scaffolding around the steel structure and sealed the work area to create a dust-free, temperature-controlled environment.

Yet, before any of this could begin, Holland Composites needed to ensure that the panels could be mounted on the steel structure with enough precision to maintain the super-flat façade. If one of the 185 panels was set a millimeter too far in either direction, the shape of the entire 100m by 25m (328-ft by 82-ft) façade would be distorted. In all, 1,800 anchor points had to be positioned on the backsides of the panels with submillimeter accuracy. Anchors were attached in postproduction at the manufacturing facility.

“Accuracy is the key when working on such a large façade,” stresses Janssen. “We always use 3-D techniques for our measuring, both for our molds and products in-house, as well as on the job site,” he explains. “Initially, we were able to produce an accuracy of ±3 mm [±0.19 inch] for each anchor position.” To ensure accuracy, 3-D laser measurements were used on the job site to map the exact position of each of the mounting points on the steel structure and identify which anchors needed to be adjusted, and by how much, to achieve zero tolerance.

To make the required adjustments, a set of six plastic caps were developed that fit over the mounting points already welded to the steel structure. The caps could shift the position of the anchor point by 1, 2 or 3 mm, (0.039, 0.079, or 0.118 inch), either forward or backward. Using a map of the mounting block locations, workers were able to place all the necessary caps prior to panel installation.

To position the panels against the anchor points without marring the panel’s outer surface, Holland Composites had to develop another custom solution. “We completely engineered and commissioned the building of a vacuum mounting tool for this project,” explains Janssen. The tool is designed as an attachment for a forklift and employs vacuum clamps to grip the composite skin, similar to how panes of glass are handled. Holland’s Composites’ production personnel received special training to operate this machine, which can twist and tilt the panel with exacting accuracy.

“It allows the operator to remotely control the panel while standing on the scaffolding or high worker [lift bucket]. So, they can actually see the anchor points on the steel structure in relation to the corresponding anchor points on the backside of the panel,” he explains. “This allowed them to precisely move the panels into position.”

Challenge 4: Sealing the seams

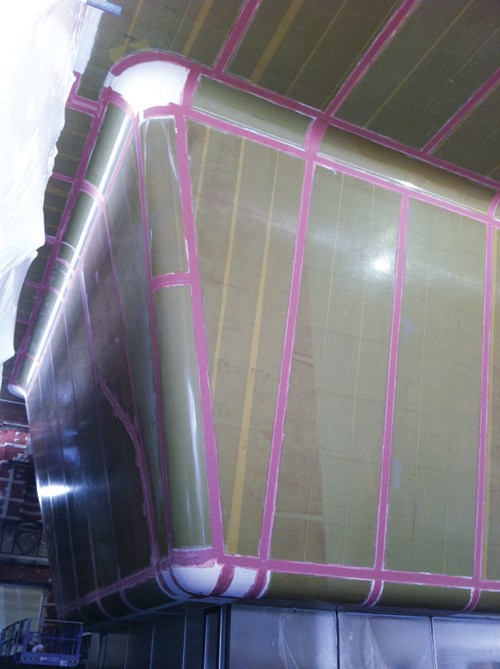

After the panels were mounted, a wet laminating process was used to create the seamless surface. The panels were manufactured with left and right sides designed to interlock after the panels were in place, explains Janssen.

“On the left side of the panels, holes were drilled completely through the sandwich structure, while on the right side a backing plate was attached that would sit behind the holes,” he explains. “We injected vinyl ester resin through the holes to bond the panel to the backing plate of the panel next to it. This was necessary because we didn’t have access to the backside of the panels.”

Next, the small gaps (less than 51 mm/2 inches) in between the panels were filled with polyisocyanurate foam and covered with prepared strips of aramid/carbon/glass laminate. “Each of the large panels had a slight recess on the side of the outer edge to allow for the laminate strip to be placed without disrupting the surface,” explains Janssen. After they were bonded with vinyl ester resin, the laminate strips created a strengthening connection between the panels, ensuring that the façade panels would acts as one large composite structure.

Temperature control within the work space was critical for both resin mixing and the spray coating operation needed to apply the topcoat. Winter in Amsterdam typically brings frigid temperatures, and workers needed the temperature inside the workspace to range from 15°C to 18°C (59°F to 64°F). “We had to maintain this temperature not just at ground level, but all the way to the top of the structure,” adds Janssen. “You can’t have a temperature variation from top to bottom because the coating will react differently, which can create a variation in the shine of the coating,” he explains.

To avoid any visible striping in the topcoat, the entire structure had to be coated in one pass, adds Janssen. “When you’re spray coating such a large structure, you can’t have one side getting hard while you’re spraying another part,” he says. “We worked in teams of painters, sometimes as many as 15 painters at a time. Everyone had very specific jobs, and once the process began, it couldn’t be stopped.” The coating process was completed in four phases, with the entire structure coated during each phase.

In the end, the architect’s vision of a seamless façade was achieved. Stedelijk’s Bathtub stands not only as a modernist visual icon of the museum’s artistic mission, but also as an artful expression of what can be accomplished with composites in the artful hands of architects and engineers who understand the unique behavior of these most modern of materials.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePlant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

Read MoreFyous launches infinitely reusable manufacturing mold tech

PolyMorphic Moulding technology uses 28,000 digitally controlled pins to create a shape from a 3D CAD shape in less than 20 minutes, achieving zero waste and enabling parts production 14 times faster than 3D printing.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More