Bionic design: The future of lightweight structures

Biomimicry evolves into a systematic design process for optimizing efficient, lightweight structures.

NOTE: click on the links in the image sources and throughout this blog

to see more articles on bionic design and biomimicry.

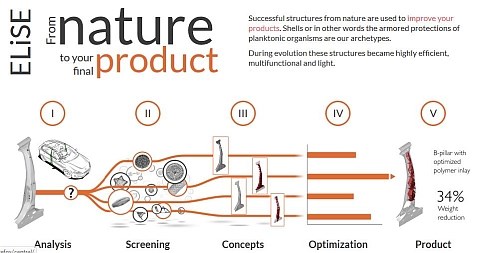

Evolutionary Light Structure Engineering (ELiSE) is a systemized approach to design optimization that uses lightweight, multifunctional structures from nature to achieve weight savings of 50% and shortened development times. Led by Dr. Christian Hamm at the Alfred-Wegener-Institute, Helmholtz Centre for Polar and Marine Research (AWI, Bremerhaven, Germany), ELiSE comprises a group of bionics experts and design engineers that have completed projects for a wide array of companies in the automotive, aerospace, marine and industrial markets.

|

|

|

|

||

ELiSE has optimized bionic designs for a wide range of applications including automotive seats and B pillars, washing machine tubs, mounting brackets, wind turbine foundations, yacht hulls and CFRP grid structures. SOURCE: ELiSE, (top right) Automotive Engineering Expo 2015 and

(bottom) ELiSE home page, scroll down to References.

Bionic Design and Biomimicry

Biomimicry looks at the solutions nature has found and adapts these biological models, systems and elements to solve engineering problems. Airbus has been a proponent of bionic design for over a decade, using it to explore shark-like grooved skins for improved aerodynamics and to develop water-shedding coatings for cabin interiors and shape-changing winglets. It’s 2050 concept aircraft features a fuselage inspired by bone.

Airbus’ concept of its aircraft in 2050 include a fuselage structure based on the lightweight skeletons of birds. The bionic partition project is a first-step demonstration. SOURCE: Smithsonian.com and ArchitectMagazine.com.

The Bionic Partition Project combined generative design and additive manufacturing to demonstrate a bionic design for the A320 passenger-to-galley partition with the potential to cut weight and production steps by 50% and to increase material usage (buy-to-fly ratio) to 95%. In the video below, Airbus says it will start to look for more cabin parts to adapt and demonstrate.

Not Just Topology Optimization

In my discussion with Dr. Hamm about ELiSE, he notes that the Airbus 2050 aircraft fuselage focuses more on topology optimization, “but there is more to bionic design than this.” His team is not just optimizing placement of material to more efficiently handle structural loads (topology optimization), but is also exploring the nanostructure of materials. “It’s not either geometry or material composition, but both,” he says.

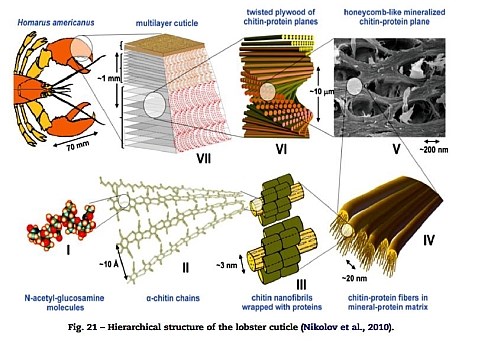

What Hamm is talking about is hierarchical structures, a common solution found in nature, where the multi-scale organization — from the nano to macro level, (see below) — of ordinary building blocks produces extraordinary properties. “Look at nacre, for example,” says Hamm, “which consists mainly of a very brittle material, calcium carbonate. But due to its hierarchical structure, it is tough. However, it is always used in nature in flat structures, not complex shapes. But what we are working on are very complex geometries as well as complex nanostructures.” He advises to look at the work of Markus J. Buehler at MIT.

Chitin as a building block is used at the Angstrom, nanometer and micrometer levels of a lobster shell, but organized uniquely at each, to produce a hard yet resilient structure. SOURCE: “Bio-mimetic mechanisms of natural hierarchical materials: A review”

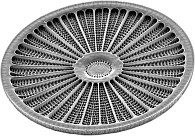

Narrowing Natural Models to Diatoms

“We basically focus on just one area, which is diatoms,” says Hamm. “The nice thing about these biological structures is that they are very clearly divided from other groups of organisms, yet they have a huge diversity, roughly 100,000 different forms. They also feature lightweight structures. For example, plankton must float in the ocean yet the material used as armor is much denser than the seawater, so it has to be a lightweight construction.” AWI also has one of the world’s largest diatom collections, which is very well curated, as well as a significant digital database attached. “So this is a very good basis for our work in lightweight bionic design, but we do consider other organisms, for example the more elongated sponge for the Stadco B pillar project.”

Diatoms comprise 100,000 forms, many of which are quite "out of the box"

thanks to their formation process. SOURCE: ELiSE.

Another key benefit to diatoms is their production process. Hamm says they can build whatever forms they want to, whereas a tree is much more limited in the forms lignin and cellulose can create. He explains, “The diatoms’ structures precipitate within vesicles which are bordered by flexible membranes, whose geometries are manipulated by the cytoskeleton, so crazy forms can be developed.”

How Does ELiSE Work?

ELiSE is a systemized bionic design process which usually begins, says Hamm, with customers presenting their high-potential candidate structural designs for projects like car interiors, offshore wind turbine foundations, etc. It is then important to understand how much freedom is allowed for design alternatives and project requirements.

Hamm explains, “If you have very little design freedom — [i.e. if the constraints prohibit much exploration of alternatives] — then that affects the scope of the approach.” It is also important to understand the design drivers. For example, is it more important to achieve lightweight or to use a cheaper material? “It is also crucial to detail all of the load cases,” Hamm adds. “You have to know what all of the technical challenges are. These are often not as well-known as they should be.”

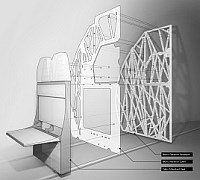

The process steps in the ELiSE process can be seen in this automotive B pillar case history.

SOURCE: ELiSE.

The team then makes a road map for the customer, outlining scope, budget and schedule options. Once the customer finalizes those details, the ELiSE team begins its screening process, looking at models in nature. “We create preliminary designs as starting points,” says Hamm, “and either optimize them in parallel or take one with the highest potential and provide a range of optimized variations. But we also validate along the way. We establish a benchmark of what the state of the art is so that we can evaluate our development.”

He notes that design optimization is a large topic in itself. “We create parametric models based on the natural geometry that can change easily and allow beta offspring. We pick the best and it creates offspring. So it’s a bit like evolution. But you need a starting point and this is what we do well.” The steps involved in the ELiSE process are illustrated in the B pillar example above.

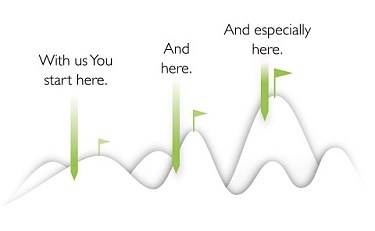

The starting point of lightweight structure optimization is critical.

By analyzing different optimization scenarios, ELiSE aims for a perfect balance between weight reduction, producibility and production costs.

“The idea is that optimization is not climbing one hill,” says Hamm, “but is instead like a mountain range with many peaks and you don’t really know where you are.” It makes sense to climb one peak to get a view. “You have so many parameters you can vary,” he adds. “It’s good to use very different approaches to the same problem in order to develop a landscape of the optimization options, and thus, be able to identify which offers the best overall solution. Hamm notes that ELiSE has been standardized in cooperation with the Association of German Engineers (VDI, Düsseldorf) as a biomimetic process to generate lightweight solutions.

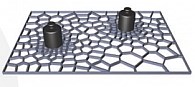

Ideas Like Load-adapted Honeycomb

The outer shells of diatoms are made of glass-like material, with some having unusual honeycomb structures. Unlike classic honeycomb structures of bees, the diatoms structures are adaptive which enables load-optimized design. Where the geometry needs to carry less loads, less material is applied. This creates opportunity for dramatic weight savings and structural efficiency.

By putting more material where a structure must handle more load, honeycomb with varying cell diameters and heights can achieve significant weight savings while increasing stiffness. SOURCE: ELiSE and ELiSE AuST project (right).

Hamm says ELiSE can be used to design a load-adapted honeycomb structure with optimal diameter sizes and wall thicknesses, improving stiffness and cutting weight by 20-50% compared to classical structures. The irregularity of the cells also affects the structure’s vibration properties.

Another project, “ELiSE AuST — Automation and standardization of the bionic ELiSE process”, was part of the research project BIO-OPT, which looked at automation, validation, benchmarking and standardization of bionic optimization processes. Funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), ELiSE AuST led to exciting results with regard to development of bionic stiffening structures. One of the main objectives was to develop generic algorithms for the automated, load-dependent and adaptive dimensioning of surface stiffening structures in lightweight designs. This helps automate the design process, making it less time-consuming.

As part of this work, a design case was explored where a surface uniformly stiffened with a constant-height honeycomb was compared to a bionic design where the honeycomb varied in height and diameter, according to mechanical loading. The bionic design reduced weight from 621 g to 497 g without violating displacement and maximum thickness constraints.

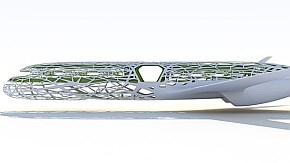

Cocoon_FS project used FRP “petals” to create a lightweight yet strong aesthetic building. SOURCE: Inhabitat.com.

Composite Applications

The lightweight fiber reinforced plastic (FRP) pavilion Cocoon_FS was designed within the AWI-based Virtual Helmholtz Institute PlanktonTech and completed with Berlin-based firm Pohl Architects. “It evolved out of the German bionics network called BioKoN,” says Hamm, “which includes a range of different working groups and partners, but in PlanktonTech we had also research partners from the US (e.g. Andrew Knoll from Harvard). We suggested the idea of the fractal structures, and the architects developed the hands-on methods for the FRP construction.” The project demonstrated bionic design’s ability to create an eye-catching prefabricated structures featuring a translucent shell, low material usage, a high strength-to-weight ratio and easy transport. “We wrote a book on the whole Virtual Helmholtz Institute PlanktonTech," Hamm notes, "which includes the pavilion and other composite solutions.”

In the bionic automotive side bumper project, the biological archetypes chosen for concept development featured sophisticated crash behaviors. The five most efficient concepts were determined by comparing their energy absorption capacity from explicit crash simulations. The best performing concept for the internal structure of the side bumper was determined and used to develop a composite material for the structure.

A thermoplastic matrix reinforced with carbon fibers was used to create adaptive, load optimized honeycombs. Due to the high energy absorption of the bionic concept, the occupant protection performance remains unchanged, even with a very low weight construction.

ELiSE is also seen as an enabler for new structural paradigms geared toward additive manufacturing, including the bionic bike design it has developed — reportedly the lightest aluminum folding bike in the world.

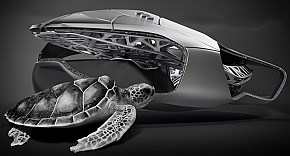

ELiSE's bionic bike (left) and EDAG's GENESIS passenger safety cell (right)

highlight bionic design's ability to exploit the new freedoms offered by additive manfuacturing. GENESIS is based on a protective turtle shell, where the finely structured bone interior produces strength and stiffness. SOURCE: ELiSE and EDAG.

Related Content

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More