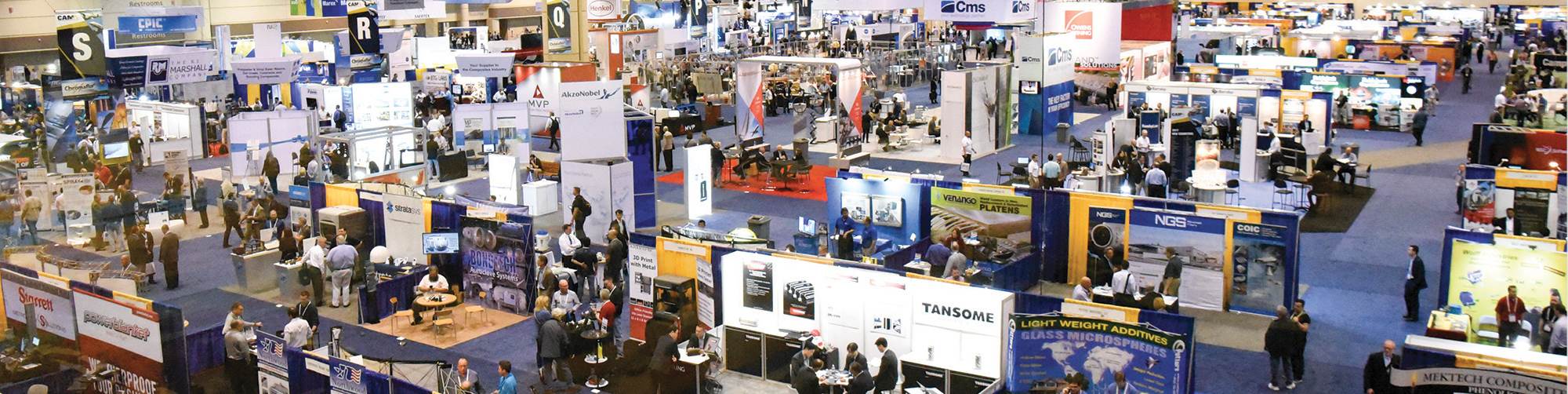

Composites professionals from North America and a significant number from the global composites community have already marked their datebooks for the upcoming CAMX 2018 event. The Composites and Advanced Materials Expo, which will be held Oct. 15-18, 2018 at the Kay Bailey Hutchison Convention Center in Dallas, TX, US, is co-produced by the American Composites Manufacturers Assn. (ACMA, Arlington, VA, US) and the Society for the Advancement of Material and Process Engineering (SAMPE, Diamond Bar, CA, US). The CAMX conference program is taking shape, and invaluable opportunities for networking and collaboration await.

This year, CAMX will co-locate with the Industrial Fabrics Association International’s (IFAI, Roseville, MN, US) IFAI Expo 2018. The pairing is a naturally good fit: CAMX is North America’s go-to composites event for products, solutions and networking and IFAI Expo is the premier expo for new and innovative products in the field of industrial fabrics, key components of many composites. Attendees and exhibitors will benefit from expanded networking and sharing among the impressive national and international audiences that CAMX and IFAI attract. Because new innovations presented by exhibitors will often be of interest to attendees at both events, the exhibit halls for the shows will be combined, but the conference programming and registration for the two events will remain separate.

“The goal of this co-location is to expand the relationship between the technical textiles and composites industries for our attendees and exhibitors,” says Andrew Aho, IFAI’s VP of new business development. “We want to capitalize on the current synergy between these industries and promote future collaboration.”

CAMX features pre-event, in-depth tutorials (Monday, Oct. 15 and Tuesday, Oct. 16), and three days of conference programming, featuring technical papers and presentations arranged in multiple topical tracks. Monday’s tutorials will include “Thermoplastics Composites: Technology, Applications and Developments in Aerospace,” presented by Arnt Offringa of GKN Fokker (Redditch, Worcestershire, UK and Papendrecht, Netherlands), and “Enabling Technologies for Bonding and Joining Composites,” presented by Lou Dorworth of Abaris Training Resources (Reno, NV, US).

On Tuesday, Avner Ben-Bassat of Plataine (Waltham, MA, US) will speak in depth about digital manufacturing in the tutorial “Entering the Digital Factory Era: Thinking AI, Implementing AI.”

The technical program will be arranged in the following tracks:

- Additive Manufacturing

- Advances in Materials

- Business, Regulatory & Workforce Development

- Design, Analysis & Simulation

- Green & Sustainability

- Manufacturing and Processing Technologies

- Market Applications

- Non-Destructive Evaluation and Testing

The opening General Session, CAMX Live!, takes place on Tuesday morning Oct. 16. It will feature an industry innovator to be announced soon. Following the General Session, the expansive exhibit hall opens at 10:00 a.m and extends through 1:00 p.m. on Thursday, Oct. 18. The CAMX closing luncheon will take place at 1:00 p.m. on Thursday.

Innovation Park, an Exhibit Hall enhancement introduced at CAMX 2017, delivers a new way to learn and engage. Consisting of specialized zones for learning, networking and inspiration, this feature provides a new way for CAMX attendees to interact. Cultivate a fresh experience centered upon solving your challenges, meeting like-minded professionals, and taking in presentations in a fresh new way. CAMX 2018 Innovation Park programs are under development. Ask the Experts, to be held at Consultant’s Corner, will give attendees an opportunity to meet one-on-one with industry veterans and get valuable insights based on their years of experience. Attendees are encouraged to bring their challenges, ideas, plans or samples to get a fresh perspective from consultants about how to move forward. Campfire Sessions, at either end of Innovation Park, foster learning from subject-matter experts and sharing of ideas about new trends, ideas and industry developments.

Curious how composite materials can solve your traditional material challenges? This free session track held in the Exhibit Hall gives manufacturers access to several presentations designed to help you understand more about composites. Sessions include Composites 101, a 45-minute introduction to composite materials; Composites Success Stories, during which companies will give 10-minute presentations on how they have used composites to solve a specific challenge; and Composites is the Solution, a roadmap/overview of how a manufacturer might take steps to integrate composites into its manufacturing processes.

As always, SAMPE’s Fellows Award will be presented to distinguished members who have served the organization as well as contributed to the fields of materials and processes. The 2017 Class of Fellows will be presented at the SAMPE Awards dinner, held Monday evening, Oct. 15. ACMA will likewise present its Membership Awards and Recognition Ceremony at a reception the same evening.

For updates, new announcements and logistical information as the show approaches, check the CAMX web site | thecamx.org

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More