Exhibitors have descended on Dallas for the more than 130 presentations and 360+ exhibitors showcasing their capabilities and the projects they’ve been working on, despite the pandemic. Day 1 and 2 were full of networking, demonstrations and unparalleled innovations. Photo Credit: CW

Seven hundred and forty four days after the iteration of CAMX 2019, composites exhibitors and attendees were finally able to come back together. It was agreed that the turnout for this year’s trade show was larger than expected, and the visual aspects of it — such as Composite One’s (Schaumburg, Ill., U.S.) demo booth at the center of the hall — were a big hit after such a long period of isolation.

Moreover, it was made abundantly clear that composites fabricators and engineers had been far from idle since the shutdown back in March 2020. As the CAMX media sponsor, CompositesWorld reported on several of these developments from CAMX Award and ACE Award winners, to several new or interesting technologies on display in the CAMX Show Dailies. Below is an aggregation of this work.

CAMX Awards recognize innovation in rail, materials

By Jeff Sloan, Editor-in-Chief, CompositesWorld

Ken Huck, director of product development at TrinityRail, received the Combined Strength Award (left). The Unsurpassed Innovation Award went to Mitsubishi Chemical Advanced Materials (right). Photo Credit: CW

CAMX 2021 was officially kicked off yesterday with the General Session, which included the announcement of the winners of the CAMX Awards. There are two CAMX Awards, one called the Combined Strength Award and the other called the Unsurpassed Innovation Award. Nominees this year were highly diverse and spanned a variety of end markets, applications, materials and processes.

TrinityRail entry. Photo Credit: CW

The winner of the Combined Strength Award went to TrinityRail (Dallas, Texas, U.S.) for a first-of-its-kind composite primary load floor the company developed for one of its refrigerated boxcars. Developed in cooperation with Composite Applications Group (CAG, McDonald, Tenn., U.S.), Wabash National (Lafayette, Ind., U.S.) and Structural Composites (Melbourne, Fla., U.S.), the composite floor replaces an all-steel legacy structure and enabled a 4,500-pound weight reduction in the boxcar. The design also allowed TrinityRail to innovate a secondary floor that allows easy transition for transport of frozen food or fresh produce.

Ken Huck, director of product development at TrinityRail, received the award and thanked TrinityRail’s composites industry partners for their help on the project. He also described the composite primary floor as marking a “new era for composites in the rail industry.” He also noted that TrinityRail is working on other composite structures in other rail applications. “We will have more exciting things to show you soon,” he said.

Mitsubishi Chemical Advanced Materials entry. Photo Credit: CW

The Unsurpassed Innovation Award went to Mitsubishi Chemical Advanced Materials (Mesa, Ariz., U.S.) for its entry titled “High-Volume Structural Carbon Fiber-Reinforced Injection Molded ETP Composite.” The focus of the entry is Mitsubishi’s new injection moldable KyronMAX carbon fiber/nylon material that offers a tensile strength of more than 50,000 psi/345 MPa. Mitsubishi describes KyronMAX as the strongest injection moldable material in the world and says the performance of KyronMAX is attributable to the sizing technology the company developed, which allows short fiber reinforcements to exhibit the mechanical properties of long fibers (>1 mm). The material was launched on the MY 2021 Jeep Wrangler and Jeep Gladiator, used to mold receiver brackets that attach the roof to the vehicle.

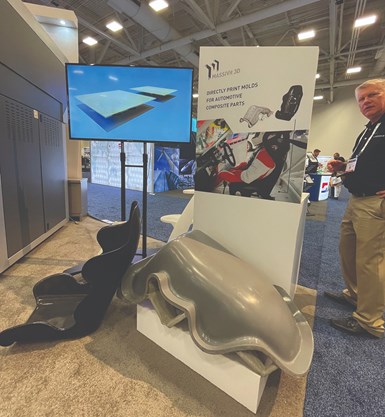

Massivit 3D displays fast, 3D-printed tooling for composite parts

By Hannah Mason, Associate Editor, CompositesWorld

Photo Credit: CW

On the show floor, Massivit 3D (Lod, Israel) is displaying its Massivit 3D printing system for producing fast, 3D-printed tooling for the production of composite parts.

The goal is fast tool production, says Jeff Freeman of Massivit 3D — reportedly a week or less for a finished mold compared to many weeks for traditional tooling. Using Massivit’s gel dispensing printing (GSP) technology, the system prints a hollow mold “shell” from a UV-curable, acrylic-based thermoset gel. This material is water-breakable — not water-soluble, so the material doesn’t contaminate the water. The shell mold is filled with a liquid epoxy and then the whole structure is oven-cured and then submerged in water so that the acrylic shell breaks away. The resultant mold is said to be an isotropic, durable, strong mold with properties capable of hand layup of composite parts. According to Massivit 3D, materials R&D on the resultant epoxy mold material is ongoing, including the addition of fibers or other reinforcements or fillers to reduce weight or add properties for various applications.

The Massivit system can also print water-breakable interior mandrels for use in producing hollow, complex-geometry tube-shaped composite components. The inner mandrel is printed, and then after layup of the composite component, it is broken up by submersion into water, leaving the final part.

The company has a beta machine on display at the show with a demonstrator seat component and hollow tube-shaped part. Massivit plans to start selling machines starting Q1 2022. The current system on display has a temperature capability of up to 120°C (250°F), and the goal is to release a system capable of temperatures up to 180°C.

Current target application areas include medical and automotive components, and Freeman notes that aerospace-grade components will likely be possible in the near future.

Re:Build Manufacturing advances onshoring initiatives for composites

Photo Credit: CW

Re:Build Manufacturing’s (Framingham, Mass., U.S.) primary focus centers around returning manufacturing to the U.S. It is composed of a collection of companies — including the recent purchases of Oribi Manufacturing (Commerce City, Colo., U.S.), Cutting Dynamics Inc. (CDI, Avon, Ohio, U.S.) and Composite Resources (Rock Hill, S.C., U.S.) — covering the entire supply chain, from design, to production and assembly, and brings a holistic approach to composites; Re:Build uses thermosets, thermoplastics, carbon, glass and natural fibers for a wide variety of applications. Further, the company says it has acquired multiple engineering service groups equipping them with more than 200 engineers to design the products and processes which will make reshoring of advanced manufacturing in the U.S. increasingly possible. Re:Build is specifically showcasing its advanced materials group at CAMX.

ACE winners represent variety of material, process innovations

By Jeff Sloan, Editor-in-Chief, CompositesWorld

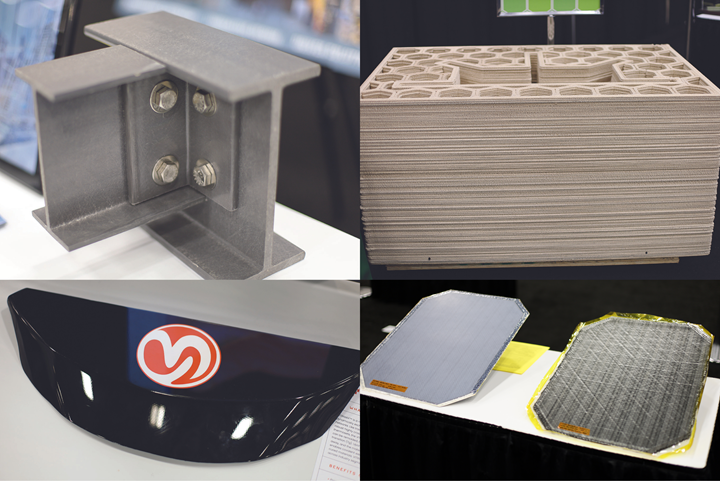

A few of the ACE Award winners for CAMX 2021. (Top left) Frost Engineering & Consulting, (top right) Oak Ridge National Laboratory, (bottom left) Mallinda Inc. and (bottom right) Victrex.

The American Composites Manufacturers Assn. (ACMA, Arlington, Va., U.S.) yesterday hosted the awards ceremony for its Awards in Composites Excellence (ACE) competition. ACE recognizes nominees and winners in six categories that include innovation in green design, application creativity, equipment and tooling innovation, material and process innovation, sustainability and potential for market growth.

- Innovation in Green Composites Design. The winner here is Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) and the University of Maine (Orono) for its entry titled “Additively Manufactured Foam Biocomposites for Lightweight Structural Applications.” ORNL develops additively manufactured (AM) biocomposites through in-situ foam extrusion using a biocomposite matrix (biopolymer (polyactate)) and biofiber reinforcement (wood and microcellulose fibers) for low embodied energy and a low carbon footprint. Use of biofibers improve rheology, printability, composite performance and foaming behavior, ORNL says, and enable the manufacture of custom parts for applications such as boats, drones and packing/transportation molds.

- Most Creative Application. Frost Engineering & Consulting (Mishiwaka, Ind., U.S.) and the University of Notre Dame (South Bend, Ind.) are the winners here with their entry “Large Pultruded FRP Multi-Story Frame in Region of High Seismicity.” Frost designed a two-story access platform and utility support structure in Santa Clara, Calif., U.S., with a footprint of more than 7,000 square feet for rapid deployment within highly constrained site conditions and a construction schedule that precluded use of structural steel.

- Equipment and Tooling Innovation. 3D printing specialist Massivit 3D (Lod, Israel) is the winner in this category for its entry “Massivit 10000 — Digitalizing Tool for Composites Manufacturing with Advanced Additive Manufacturing.” The Massivit 10000 system 3D prints a sacrificial shell and intermittently casts an industrial-grade, dual-component thermoset epoxy into that shell via a second head. The mold and shell are then immersed in water, causing the shell to fall off the epoxy mold.

- Material and Process Innovation. The winner here is thermoplastic composite materials manufacturer Victrex (Conshohocken, Pa., U.S.) for its entry titled “Achieving Thermoset AFP Speeds with Thermoplastics.” Working with Electroimpact (Mukilteo, Wash., U.S.), Victrex demonstrated use of laser-based automated fiber placement (AFP) technology to achieve laydown speeds of 100 meters/minute of in-situ consolidated carbon fiber/LMPAEK prepreg tape.

- Composites Sustainability. Mallinda Inc. (Denver, Colo., U.S.) is the winner in this category for its nomination of “Vitrimers: Reprocessable Thermosets Unlock the Circular Economy for Composites.” Mallinda is commercializing a material technology based on a vitrimer chemistry in which an epoxy resin is cured and crosslinked like a traditional thermoset, but can be reformed or recovered for other use via chemical unlinking of bonds.

- Infinite Possibility for Market Growth. The winner here is GEOTEK (Stewartville, Minn., U.S.) for its entry titled “PUPI Fiberglass Transmission Crossarms.” GEOTEK’s PUPI crossarms are, compared to wood, 170% stronger, 41% lighter and expected to have a service life of more than 60 years.

L&L Products displays two-component adhesive, CCS process

Photo Credit: CW

By Ginger Gardiner, Senior Editor, CompositesWorld

L&L Products (Romeo, Mich., U.S.) is displaying its PHASTER XP-607 two- component rigid foaming adhesive that offers structural bonding to composites, aluminum, steel, wood and cement without surface treatment. PHASTER does not crumble but offers high toughness via a 100% closed-cell foam that is tappable for mechanical fastening and also inherently fire resistant. PHASTER’s flexibility in formulation also allows its use in gasketing and sealing applications. All PHASTER formulations are VOC-free, with no isocyanurate and no air permit requirements.

L&L is also highlighting its Continuous Composite Systems (CCS) pultruded products, featured in the 2021 Jeep Grand Cherokee L composite tunnel reinforcement, which was recognized with a 2021 Altair Enlighten Award, along with partners BASF (Wyandotte, Mich., U.S.) and automaker Stellantis (Amsterdam, Netherlands). The part features a continuous hybrid glass and carbon fiber/PA6 pultruded CCS overmolded with unreinforced PA6.

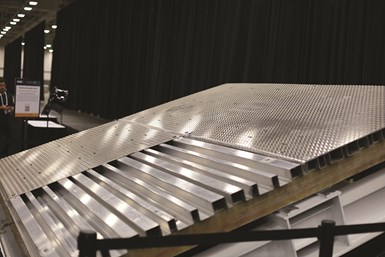

IDI Composites showcases CFRP wheels ready for low-cost, high-volume production

By Hannah Mason, Associate Editor, CompositesWorld

On display this week at IDI Composites International’s (Noblesville, Ind., U.S) CAMX booth, X27, is a Coyote Mustang sporting carbon fiber composite wheels made by Vision Composite Products (Decatur, Ala., U.S.) from a combination of IDI’s Ultrium U660 carbon fiber/epoxy sheet molding compound (SMC) and braided preforms from A&P Technology (Cincinnati, Ohio, U.S.).

Darell Jern, senior project development specialist at IDI Composites, says the wheels are the result of a five-year collaboration between the companies and are the first components to use IDI’s U660 1-inch chopped fiber SMC. The compression molded wheels, produced at Vision Composite Products’ facility, are said to exhibit a 40% weight reduction compared to aluminum wheels, as well as low density and high strength to meet all SAE wheel regulations.

The carbon fiber forged wheel, displayed on the CAMX show floor. Photo Credit: CW

“It was a great collaboration with Vision all the way through,” Jern says. “We worked with them through multiple iterations and material development to get the results we wanted.” The epoxy-based SMC was developed to meet the high strength requirements, and were put to the test in a 48-hour durability test.

Jern adds that these are cost-effective, U.S.-made products are capable of producing wheels at high volumes for lightweighting racecars, utility terrain vehicles (UTV), electric vehicles (EV) and more. He notes that Ultrium U660 is suitable for many other types of automotive applications as well, in the vehicle interior and exterior, with more projects underway.

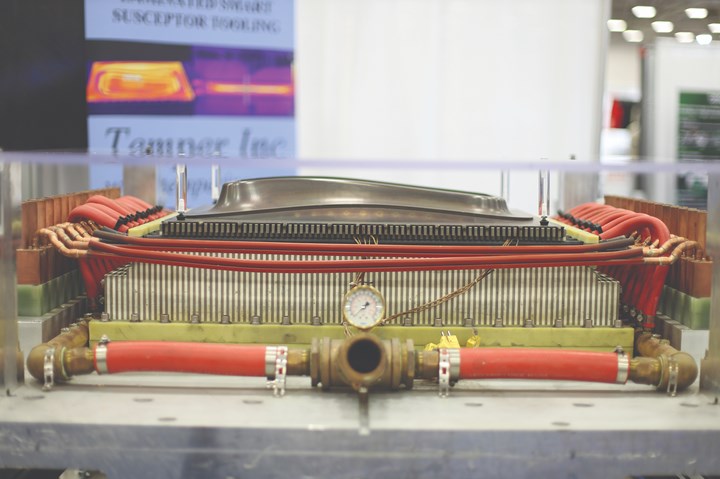

Metyx Composites represents Adapa reconfigurable molds, emphasizes manufacturing capabilities

By Grace Nehls, Assistant Editor, CompositesWorld

Photo Credit: CW

As a U.S. representative of Adapa A/S (Aalborg, Denmark), Metyx Composites (Istanbul, Turkey and Gastonia, N.C., U.S.) exhibits the company’s adaptive mold technology at booth S20 as a solution for composite parts with dimensional and geometric complexity, including applications in aerospace, marine and construction, to name a few. The intelligent, reconfigurable mold, offered in sizes up to 10 x 10 m (approximately 33 x 33 ft), uses a 3D file or model, which is then panelized into smaller pieces to fit the mold. Once this is complete, the file information is fed into the mold’s control unit, and each individual panel can then be modified to the desired shape.

Photo Credit: CW

The adaptive mold is comprised of linear actuators, powered by CAM-controlled electrical step motors, which bring it into the desired 3D position, while the flexible rod system enables high accuracy and low tolerances. On top sits the 18-mm thick silicon ferromagnetic composite membrane, which stays in place by magnets attached to the rod systems; according to Adapa’s John Sohn, this silicon membrane does not need to be replaced. Resin infusion and thermoforming are some processes that are possible when using this tool. Sohn mentioned that Adapa’s more industrial partners also use it for hand layup and automation.

Metyx Composites is a manufacturer of high-performance technical textiles, which include multiaxial reinforcements, carbon fiber reinforcements, RTM reinforcements, woven reinforcements and vacuum bagging products. Its two composites-related businesses include METYX Composites Tooling Center and METYX Composites Kitting.

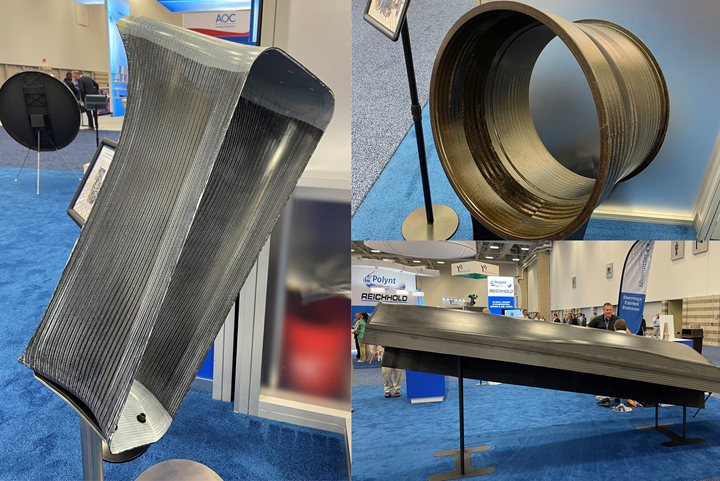

On display: DowAksa’s CFRP automotive capabilities, recycled wind blade spar cap solutions

By Hannah Mason, Associate Editor, CompositesWorld

DowAksa sub-frame. Photo Credit: CW

At its CAMX booth L50, DowAksa (Farmington Hills, Mich., U.S.) is displaying its capabilities for cost-competitive carbon fiber solutions in various end markets. Since forming in 2012 as a joint venture between Dow and Aksa, the company’s primary business has been its 70% carbon fiber/polyurethane pultruded profiles, used mainly for wind blade spar caps, according to Ramki Subramanian, managing director of DowAksa USA. “All wind blades over 70 meters today use our spar caps,” he says.

The company, he says, is expanding its carbon fiber capacity at its facilities in Turkey, leading to additional business in wind but also into other markets such as automotive, marine and other mobility markets.

On display at the show are several R&D automotive components DowAksa has built with its new line of XForge thermoset- and thermoplastic-based carbon fiber materials. For example, at the booth is a hybrid aluminum and carbon fiber-reinforced polymer (CFRP) assembly concept for a Ford Transit front sub-frame. Part of the Composite Hybrid Automotive Suspension System Innovative Structures (CHASSIS) project, the component incorporated DowAksa’s XForge VZ (for the rear beam) and XForge VF (for upper and lower panels), and is said to have achieved a 41% overall weight savings over the original steel assembly.

Also on display is a floor plan concept part, which also incorporates XForge VZ and XForge VF products. Part of Aston Martin’s Continuous And Discontinuous Fiber Engineered Composites (CADFEC) project, two separate composite materials were co-molded in a fully automated process and achieved a weight savings of 31% compared to the original aluminum assembly.

According to Subramanian, within its wind business, DowAksa is also looking into ways to reuse carbon fiber composite pultruded parts at a wind blade’s end of life (EOL). One development on display at the show is the use of recycled wind blade pultrusions to reinforce wooden beams used in construction, which Subramanian says increases stiffness and ultimately the capability for increased beam length.

Alpine Advanced Materials targets conversion opportunities

By Jeff Sloan, Editor-in-Chief, CompositesWorld

At left are two identical parts, one machined aluminum with metallic coating, the other molded HX5 with the same coating. At right are two identical HX5 parts, one painted and coated. Photo Credit: CW

The thermoplastic resin systems typically used in composites fabrication include PEEK, PEKK, PAEK, PEI, PES and nylon. Joining that list is HX5, an engineered thermoplastic formulation developed by Lockheed Martin Skunk Works and now offered by Alpine Advanced Materials (Dallas, Texas, U.S.), booth U47.

HX5 is offered in pelletized format for injection molding or extrusion. Its chemistry is proprietary and includes a carbon fiber reinforcement and a nanofiber to enhance mechanical performance. The material’s mechanical properties are substantial and Alpine has positioned it as an alternative to aluminum. It has RT tensile strength of 38.2 Ksi, RT tensile modulus of 4,000 Ksi, RT compression strength of 43 Ksi and RT compression modulus of 1,240 Ksi.

Alpine, however, is doing more than supplying HX5 into the marketplace. The company is also providing part design engineering, mold design and manufacturing services. Roger Raley, president, says moldmaking and injection molding is provided by third party manufacturers. Alpine also offers HX5 in billet format that can be CNC machined.

Raley says HX5 offers very low viscosity and flows easily into deep-draw and complex molds. Further, he notes that Alpine’s manufacturing strategy allows it to source injection molding with flexibility and scalability, depending on the needs of the customer. HX5 is also highly receptive to coatings and plating, whether for decorative or functional purposes, including EMI shielding.

Related Content

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More