Composite spoilers brake Airbus for landing

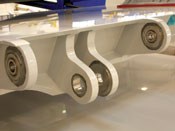

New RTM'd carbon composite center hinge fitting withstands 20-ton air load in commercial jet spoiler assembly.

Aerospace composites manufacturer Fischer Advanced Composite Components AG (FACC) is building innovative new spoiler assemblies for aircraft manufacturer Airbus Industrie's A330-300 and A340-500/600 commercial aircraft (see the sidebar "Function and operation of aircraft spoilers," at the end of this article or under "Editor's Picks," at right). Until recently, Ried, Austria-based FACC built the spoilers from composites but used a die-forged, heat-treated aluminum center hinge fitting for attachment of the spoiler to the wing. While the aluminum fitting meets the design specification, it is procured from a metal supplier at considerable expense and with an unacceptably long lead-time, says Elisabeth Ladstaetter, head of R&D and process engineering for FACC.

Two years ago, FACC began to look for an alternative to the aluminum fitting and entered into a highly successful technology partnership with Cytec Engineered Materials (Tempe, Ariz.), where engineers customized a previously developed technology for use with FACC's spoiler/center hinge fitting assemblies. The fitting was made possible by a unique preform concept that reduced cost, weight and manufacturing time, met all design allowables and ultimately led to flight certification and acceptance by Airbus. The result is a composite center hinge fitting made by resin transfer molding (RTM), which then can be integrally cocured with the spoiler in an autoclave.

Founded in 1989 to develop and produce composite aircraft components, FACC is a subsidiary of Fischer Ski-Tennis GmbH. The company has established a reputation as a specialist in the design and fabrication of aerospace systems and annually delivers $200 million (USD) of composite products to a customer base that includes Airbus, The Boeing Co., Bombardier, Rolls-Royce, Spirit, Alenia, Goodrich and other high-profile aerospace companies. Even so, designing a carbon composite spoiler assembly that would incorporate a composite center hinge fitting, reduce weight and still meet mechanical design allowables posed significant challenges.

Making the impossible possible

Ladstaetter defines the main challenges faced by the team: first, designing a preform for the complex configuration of the fitting that could meet performance specs and be manufactured successfully; second, integrating and bonding the hinge fitting into the spoiler assembly.

To maintain the strength necessary to firmly hold the spoiler in position under severe air loads, the highly loaded hinge fitting would have to retain its mechanical properties, including compression strength, even if accidentally hit by tools or other hard objects prior to installation. High damage tolerance in terms of compression strength after impact (CSAI) was a major challenge, says Carmelo Lo Faro, Cytec's product development manager for Europe. A part with the strength and complex configuration of the center hinge fitting isn't easily made by standard methods, he points out.

Typically, pre-impregnated carbon fabric is not drapable enough to form readily into the T- and L-joints and the double curvature surface of the hinge fitting design. A liquid molding process using a dry textile would address this issue, due to the high drapability of dry fabric. However, high-viscosity toughened epoxies can't be used in injection or infusion processes with dry reinforcements; the toughened system must be replaced with a less viscous, untoughened resin in order to adequately flow and wet out the complex preform. In this scenario, however, Lo Faro cautions, "The untoughened resin would not only fail to meet the CSAI requirements but, due to its brittleness, the resin buildup along the highly stressed joints and other part curvatures would cause severe microcracking in the areas subject to internal stress."

Putting the toughener in the preform

Fortuitously, Cytec had already developed a patented preform technology trademarked PRIFORM, which proved to be the enabling alternative to the metal center hinge fitting. A key feature of this dry preforming method is incorporation of the toughener into the preform rather than the resin. The thermoplastic toughening agent currently used in Cytec's Cycom 977-2 prepreg resin system is spun into fibers, which are then combined with carbon or other reinforcing fibers into either a woven or a noncrimp multiaxial fabric. Lo Faro emphasizes that "the spinning process does not cause any chemical changes to the polymer." The thermoplastic fiber brings not only its toughening properties to the part, it serves as the binder as well, so no other binder system is needed to stabilize the dry preform.

The drapable dry fabric then can easily be formed into a complex preform configuration and processed by RTM, using an untoughened, reduced-viscosity version of Cycom 977-2 called Cycom 977-20. When heat is applied during the RTM process, the thermoplastic fibers melt and flow, mixing with the resin. The result is a lightweight, thin-walled, carbon fiber/ toughened epoxy composite part.

Lo Faro delineates the weight-to-strength advantage for PRIFORM: "In most cases, and particularly for thin structures, the main design allowable — the one that will really drive your thickness up and negate weight savings — is CSAI. Toughened PRIFORM material can save a lot of weight by satisfying the CSAI requirements."

Composite performance

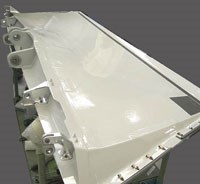

The composite spoiler assembly is built in three phases: 1) RTM manufacture of the center hinge fitting; 2) prepreg construction of the spoiler itself; and 3) autoclave cocure of the spoiler and the center hinge fitting.

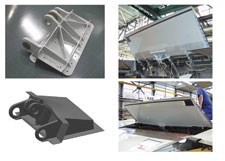

Cytec manufactures the hinge preform, spinning the thermoplastic toughening polymer into filaments and then weaving them with 6K carbon fibers from Toho Tenax Japan (Mishima, Japan) to form a 370 g/m² areal weight 5-harness satin fabric. The fabric is woven at Cytec's Greenville, Texas facility and then shipped to the company's plant in Wrexham, U.K., where it is hot-formed into the three-dimensional near-net preform at a low temperature that softens the soluble fibers but does not permit them to flow into the fabric. The process is similar to plastic thermoforming; the heated PRIFORM preform is shaped over metal tooling designed and manufactured by Cytec, which closely approximates the contours and thickness of the finished part.

Cytec ships the finished preform to Kuvag GesmbH Engineered Products Group (Neumarkt, Austria), an FACC subcontractor, for RTM processing. Kuvag loads the preform into a matched steel mold primed with Chemlease 4190 (Chem-Trend, Howell, Mich.) and injects low-viscosity Cycom 977-20 resin at an initial temperature too low to dissolve the toughening fibers (between 140°F/60°C and 194°F/90°C). This ensures that the material won't be carried away with the flow front before the resin exit port is closed. As heat increases to 284°F/140°C, the fibers dissolve quickly, and the toughener diffuses into the epoxy before the part cures at about 355°F/180°C.

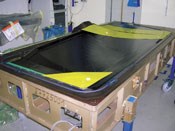

Finished hinge fittings are shipped to FACC, where they are incorporated into the spoiler's carbon composites sandwich construction. The spoiler assembly is layed up in a concave tool primed with Frekote water-based mold release from Henkel Corp. (Madison Hts., Mich.). The spoiler's prepreg skins are made from the standard toughened version of Cytec's Cycom 977-2 combined with Toho's HTA carbon fibers woven in a 2x2 twill (2x2 twill consists of two warp yarns woven over and under two fill yarns, making a more pliable fabric than plain-weave fabrics, where each warp yarn is woven over each fill yarn). The upper and lower skins enclose a Nomex honeycomb core between them. Produced by Hexcel (Dublin, Calif.), Nomex is supplied to FACC by Euro-Composites (Echternach, Luxembourg and Elkwood, Va.).

The sandwich encapsulates the RTM'd center hinge fitting. Outer skin prepreg plies are layed up first. Then the RTM fitting is cobonded with prepreg plies to form a front spar assembly, which is built into a composite top assembly. The fitting, honeycomb core and inner skin plies are added in that order. The assembly is then cocured in the autoclave at 350°F/177°C.

After demolding, the part is precision machined to remove flash and detail its contour and then drilled for attachment of edge fittings. (Since they see only minimal loads and are less expensive than RTM'd parts, the edge fittings are standard aluminum sheet metal lugs.)

Steel bushings and bearings are installed in the center hinge fitting lugs and, as the final step, the entire assembly is sealed with a polyurethane coating produced by PRC-DeSoto International (Glendale, Calif.) before the spoiler is shipped to Airbus for aircraft assembly.

Airbus installs the spoiler forward of the flap by sliding a bolt through the bearings on the lugs and connecting the spoiler to the actuator, which raises and lowers the movement of the spoiler body.

Current flight plans and future visions

The lightweight, carbon composite center hinge fitting was designed by FACC to withstand a 20-ton air load on the spoiler assembly. The new spoiler system has been installed for flight testing on one A340-600 aircraft, and 20 spoiler sets are now in production. Each wing carries six spoilers. The new assemblies save Airbus 25 percent in weight per set and saves FACC months of lead-time, waiting for metal fittings, plus the hours of assembly time once devoted to attaching them to the spoiler. "We now can produce the center hinge fitting on our own, and we are not dependent on the metal supplier that supplied our aluminum part," Ladstaetter explains, adding that FACC is contemplating "development of spoilers for future aerospace applications that will incorporate improvements into the current technology to further reduce weight and increase performance."

Cytec envisions PRIFORM as an enabling technology for RTM of other high-CSAI, toughened parts for thin-skinned primary structures, ~1-mm to 6-mm (~0.04-inch to 0.24-inch) thick, notably aircraft fuselage skins, fuselage frames, rear pressure bulkheads, wing leading edges, wing flaps and landing gear doors. Lo Faro points out that the PRIFORM thermoplastic, an aromatic polymer, is intrinsically fire retardant. Therefore, the preform material could meet fire, smoke and toxicity requirements for aircraft interiors.

The success of this cooperative project makes it clear that significant M&P technology advances can be developed and implemented when materials suppliers work closely with part manufacturers. "Working with FACC on this project has made a change in the way we approach our business," says Cytec's Lo Faro. "It was important for us to learn more about how our customers work and design parts. Thanks to this experience, we now have a team of application engineers that work closely with our customers in understanding their design requirements and helping them in making parts using our materials."

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More