COMPOSITES 2012 Highlights

As ACMA’s annual conclave convened in North America’s gambling capital, show exhibitors and attendees placed their bets on better days.

After an East Coast appearance in Ft. Lauderdale, Fla., in 2011, the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual exhibition and convention returned to Las Vegas, Nev., this year, running Feb. 21-23 at the Mandalay Bay Convention Center. The COMPOSITES 2012 show theme, “It’s All About Tomorrow’s Business,” mirrored the mood of exhibitors and visitors alike. Looking forward to new opportunities trumped looking back at lost opportunities. Confidence, that key but hard-to-measure factor in recovery from a recession, was evident among those who displayed their wares in the aisles.

Conference comment

In line with the general spirit of optimism and industry growth at the event, presenters at ACMA’s technical conference shared some insights on current research and development efforts. Jeff Martin of Martin Pultrusion Group Inc. (Oakwood Village, Ohio) explained his company’s work in the area of pultruding with two-part polyurethane (PU) resin, in contrast to traditional thermosets. PU resins generally provide higher mechanical properties than the standard thermosetting resins typically used in pultrusion, including better shear, transverse tensile and impact values. When two-part PUs are used, pultruders can dispense with some of the more costly reinforcements, such as fabrics, that otherwise are necessary to ensure that the part achieves the desired strength. The part wall thickness also can be reduced, with a corresponding reduction of part cost. And PUs don’t require styrene (see “Styrene controversy update,” below). Although an injection die, rather than a resin bath, is a necessity and, therefore, hardware costs are higher, Martin contends that the payback is a part that performs better and opens up huge markets for pultruders, including shelving and ladder rails.

What’s more, polyurethane resin formulators are addressing PU processability to improve fiber impregnation and increase pultruder line speeds, says Michael Connolly, product manager at Huntsman Polyurethanes (The Woodlands, Texas). Connolly’s paper included news about an interesting software-based modeling tool for pultrusion die and line optimization. It won the Best Paper Award in the “Pultrusion” category.

Another compelling presentation was given by Dr. Brahim Benmokrane, a professor at the University of Sherbrooke in Quebec, Canada. He described a new project in which one level of a 40-year-old, two-way flat slab parking garage was rehabilitated using only glass fiber-reinforced polymer (GFRP) reinforcing bars — roughly 40,000m/24.5 miles of bar products — to achieve a construction industry first. Benmokrane says the new slab is performing as predicted, based on in-situ monitoring instrumentation, and he predicts that the slab life could extend to 100 years.

Styrene controversy update

ACMA offered several conference sessions designed to bring composites manufacturers up to speed on styrene’s recent listing in the 12th Report on Carcinogens (RoC), issued in June 2011 by the National Toxicology Program (NTP) under the U.S. Department of Health and Human Services (HHS). ACMA lobbied heavily to keep styrene, an important polyester crosslinking component, out of the RoC, arguing that the NTP’s chemical assessment process is flawed and employs bad scientific practices. ACMA now is working to get styrene removed from the RoC (see “Styrene: Issues and Implications,” under "Editor's Picks," at top right).

On hand was George Cruzan, president of Bridgeton, N.J.-based ToxWorks, who has worked with ACMA to fight the RoC listing. He reported the latest styrene toxicity data and offered his thoughts on the prospects of delisting the material. His detailed presentation reviewed, in particular, genetic components involved in styrene metabolism in mice, rats and humans. In short, he said that new human/animal data contradict the NTP conclusion regarding potential styrene toxicity, and the weight of evidence indicates styrene does not cause cancer in humans. NTP will consider delisting a material if data support the action, but Cruzan said emphatically that “NTP will never delist styrene, no matter what the data say,” suggesting that the NTP is determined to keep styrene on the RoC regardless of contrary information.

The U.S. National Academy of Sciences has agreed to review some of the styrene toxicity data. If the Academy agrees with ACMA that styrene is not a threat, that fact might force some change, via Congressional political pressure, within NTP that could lead either to styrene delisting or a change in how NTP assesses chemical toxicity.

ACMA also announced that it has developed a Risk Communications tool kit for composites manufacturers who want or need to communicate with employees and community members about the risks associated with the use of styrene. John Schweitzer, senior director for government affairs at ACMA, told audience members that manufacturers that use styrene would benefit from a proactive program that reaches out to the community and employees about the materials used in their facility and the risks they pose. Information about the Risk Communications tool kit is available on the ACMA Web site at www.acmanet.org/resources/riskcomm.cfm.

On the show floor

In the exhibit hall, the Awards for Composites Excellence (ACE) product display area was, once again, awash with interesting concepts and innovations. In the CT spotlight were the following exhibitors and notable technologies:

Ashland LLC (Dublin, Ohio), sponsor of the ACMA’s ACE awards in the Design and Market Growth categories, highlighted its new strategic alliance with Acell in North America to promote Acell’s sheet molding compound (SMC)-based sandwich panel processing technology. It also promoted its Hetron FR 650T-20 resin, developed in response to the need for a versatile, high-performance fire retardant polyester. The new high-strength resin is a low-viscosity, promoted, thixotropic polyester with exceptional fire retardant properties. According to the company, properly fabricated laminates made with Hetron FR 650T-20 resin can achieve Class I flame spread rating in ASTM E-84 testing without the use of antimony synergists. The resin is suitable for hand lay-up, spray-up and filament winding applications. It exhibits excellent wet out properties and low drainage when applied to vertical surfaces. Its flame retardant properties make it especially attractive for use in mass transit, architectural, electrical and ducting applications.

Akzo Nobel Polymer Chemistry (Chicago, Ill.) used the ACMA conference to highlight its recent research. The company’s technical development manager Anthony Bennett presented a paper about novel alternatives to cobalt metal accelerators in polyester resin systems. Because cobalt is considered a potential hazard, particularly in Europe, the company has examined the use of chemical alternatives including vanadium, manganese, iron and others to cause decomposition of organic peroxides to ensure good cure of thermosets.

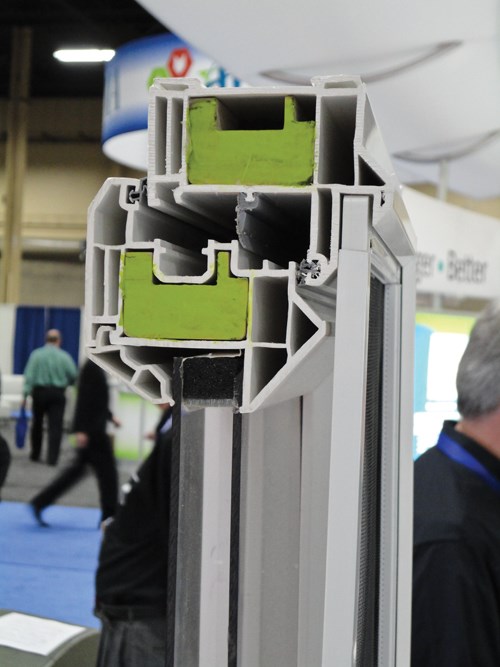

Bayer MaterialScience LLC (Pittsburgh, Pa.) emphasized its polyurethanes, focusing on the process flexibility of this material. Dominating the booth was a large (121 ft2/11.2m2) combine roof module (bottom photo), molded by Romeo RIM (Romeo, Mich.) using its new long-fiber injection press from Krauss-Maffei Corporation (Florence, Ky.). Also on display was a composite wind turbine root ring, two prototype airfoils and a high-pressure hydrogen storage tank, molded via resin transfer molding (RTM) and resin infusion. Bayer also featured two pultruded polyurethane window products — a Graham Architectural Products (York, Pa.) GThurm window frame and Deceuninck (Hooglede-Gits, Belgium) INNERGY window stiffener (top photo).

BYK USA (Wallingford, Conn.) exhibited at its booth the composite pallet, manufactured by Plastics Research Corp. (Redlands, Calif.), which was an ACMA ACE Award finalist in the Market Growth Category. BYK supplied the additives, including wetting and dispersing additives and coupling agents, that improve the performance of the finished pallet part, which is made with sheet molding compound (SMC) in a compression molding process. The pallet, weighing 54 lbs or about 25 percent less than a standard wooden version, has a maximum rated rack load of 2,800 lbs/1,272 kg.

Cerex Advanced Fabrics Inc. (Cantonment, Fla.) exhibited its line of N-Fusion continous filament nylon surfacing veils, designed for pultrusion. According ot the company, the N-Fusion veils provide a better product surface and gloss retention, better UV and corrosion protection compared to polyester materials, a high melting point above 260°C/505°F for processes that require high temperature, and improved impact resistance compared to other veil products.

Chomarat North America (Anderson, S.C.) featured its new, trademarked C-PLY bi-angle reinforcements, developed in cooperation with Dr. Steven Tsai of Stanford University and his consulting group Think Composites (Palo Alto, Calif.). Chomarat says it is committed to turning Prof. Tsai’s theory of using unbalanced laminates as building blocks for composite structures subjected to bending and twisting into industrial reality. C-PLY, in 0-25° configuration, is available in several fabric forms and a variety of fiber types, and can also be purchased as a prepreg. The 2-angle fabric offers benefits not possible with traditional balanced and symmetrical laminate architecture, such as increased strength and rigidity, less scrap during manufacturing and fewer microcracks.

Continental Diamond Tool Corp. (New Haven, Ind.) was an ACE Award finalist in the Manufacturing category, for its diamond-plated saw blades for cutting composites. Known for natural diamond as well as cubic boron nitride (CBN) tools made in an electroplating process, the company stressed the long manufacturing life of its tools, ability to maintain shape and dimensions longer than carbide tools, and faster task completion with less heat generation. The tools are up to the task of cutting fiberglass, carbon fiber or other composite materials.

Cutting Edge Composites (Summerville, S.C.) displayed its expertise in design, prototyping and production of composite products, in a broad range of applications. The company revealed that it is now the fabricator of the Proterra composite bus, previously manufactured in Golden, Colo. The company’s extensive experience in mold and plug building, as well as expertise in all types of fabrication from hand layup to resin transfer molding (RTM) has made it the fabricator of choice for many marine, aerospace, ballistics and industrial projects.

Specialty chemical company Dixie Chemical (Pasadena, Texas) attracted interest at the show for its technical paper presentations regarding the company’s “green” products: maleinated acrylated epoxidized soybean oil (MAESO), maleinated acrylated epoxidized linseed oil (MAELO), and methacrylated fatty acid (MFA) made from renewables such as palm, kernel or coconut oils, as a diluent or styrene replacement. The company, which has worked extensively with researchers at the University of Delaware, Drexel University and others, says that when compared to standard petroleum resins, MAESO and MAELO perform comparably to iso-unsaturated polyester, and that resin performance can be customized by varying the type and amount of oil-based resin and the diluent used, that is, traditional diluents are compatible with the resins. Dixie’s products have been shown to be suitable for sheet molding compound (SMC), bulk molding compound (BMC) and infusion processing, for customers wanting to reduce their product’s carbon footprint.

Dustcontrol Inc. (Wilmington, N.C.) exhibited the DC 2800 EX mobile dust extractor suitable for use in explostive atmospheres. Intended to capture dusts from handheld power tools and small table saws, the 2800 unit is equipped with a 115-volt motor and slightly longer cyclone compared to the 1800 model, which increases suction power. The 0.5 micron HEPA-certified filter is easily washable, says the company, and collected material can be recycled if appropriate.

Entropy Resins (Gardena, Calif.) displayed its pine-based epoxy resin, Super Sap, reportedly the industry’s first USDA BioPreferred-certified plant-based epoxy system. Super Sap 100/1000 has 37 percent of its resin backbone made up of naturally-occurring industrial pine oil, as documented by the USDA, and reportedly has good adhesion with reinforcements and better elongation properties than traditional petroleum-based epoxies. The company is currently targeting sporting goods applications, including Niche Snowboards (Salt Lake City, Utah). Entropy was a co-recipient of an ACMA ACE award, in the Design Category, for “Most Creative Application;” its resin was used by Nomad Mobili to create ultralight, “super green” composite furniture for life.

Eurovac Inc. (Concord, Ontario, Canada) featured its new Eurovac II Grinding Portable, outfitted with a new motor design for more power, producing more cubic feet per minute than any 110volt motor on the market. It’s on/off feature means it turns on automatically when pneumatic grinders are activated, reducing energy costs. And, the dust filtration system includes a built-in cyclone, so that particulates are forced to move to the cyclone where 85 percent of the matter is removed before the air hits the secondary cartridge filter, for much greater efficiency and less filter cleaning time.

Fiberlay Inc. (Seattle, Wash.), a distributor of fiberglass suppliers, has improved its DraGun meter/mix head, introduced last year, that can be driven by an electric hand drill or a few select ½-inch portable battery drills. Intended as a low-cost solution for small shops, the cost-effective DraGun now has a variable mix ratio, from 1:1 to 1:100, is gear-driven, pumps up to half a gallon per minute, and can pump thicker materials with an optional pressure tank, says the company. It can spray everything from polyurethane foam to casting materials.

Gruber Systems Inc. (Valencia, Calif.) highligted its “integrated process control capabilities” for composite part production, from mold design and production, to workplace soutions such as filler handling and metering equipment. Gruber produces molds for cast polymer parts, closed mold for light RTM and vacuum forming equipment. The company can design solutions for handling virtually any raw material; makes equipment for producing the parts, such as its automated remote casting mache with full recipe control system; and offers programmable logic controller (PLC) based control systems to ensure part quality control and consistency.

Gurit UK (Bristol, R.I.) featured core materials for the marine and wind markets at its booth. Trademarked Corecell, PVCell, G-Foam, G-PET and Balsaflex, all with a distinct range of properties and attributes, are available in sheet form or as tailored pieces in kit format, which the company terms “B3 SmartPac.” B3 SmartPac is a construction solution developed by Gurit that contains all of the reinforcement and core materials required for a job, precut to exact shape and size to fit the mold, and clearly labeled for alignment and location, to ensure reduced waste and better quality for the boatbuilder.

HK Research Corp. (Hickory, N.C.) introduced a new polymer called Revolution, a gel coat-like material that offers 6 percent elongation and excellent water and UV resistance. To demonstrate the polymer’s flexibility, HK Research mounted two laminates in its booth, one using the Revolution polymer and one using traditional gel coat. Both were mounted under bending stress; traditional gel coat showed cracking under load (top photo), while Revolution showed no cracking under the same load (inset). Company tests reportedly showed that Revolution, when it does crack, self-limits crack propagation and minimizes damage.

Hennecke Inc. (Lawrence, Pa.), a supplier of production equipment for polyurethane core technologies, announced the establishment of a new customer test center at its German headquarters for high-volume, high-pressure resin transfer molding (HP-RTM). With a focus on reducing part cure time, HP-RTM combines fast injection of polyurethane components into the mold, accelerated reaction and extremely short curing times, says the company. The process’s high pressure metering equipment assures reproducible results and homogeneous injection pressure, regardless of raw material and filler content, says the company.

Huber Engineered Materials (Atlanta, Ga.) has developed Micral AM550 alumina trihydrate (ATH), a finely ground flame retardant and smoke suppressant with a median particle size of about 5.5 microns. Features of the ATH include viscosity stability, controlled thickening, fast dispersion, good mechanical properties and good process flow in glass fiber composites.

Interplastic Corp. (St. Paul, Minn.) displayed, among many other products, its trademarked Integrity high-performance gel coat, one of the company’s CoREZYN thermosets. The product, which is MACT-compliant, exhibits good resistance to sagging during application, outstanding weathering characteristics and good color stability, ease of spray-up, blister and crack resistance and low porosity. A wide range of colors are available, or custom colors can be created.

SprayCore (Clearwater, Fla.) exhibited a new product, SC 4600 HTT, a sprayable, high-temperature mold-building resin. Designed for the tub/shower industry where metal molds are common, the vinyl ester-based material can be sprayed onto a pattern to quickly form a tool without surface distortion that, says the company, increases mold strength by up to 20 percent while reducing cost and time. ITW SprayCore says the product makes a cost-effective alternative even with multiple part pulls.

JRL Ventures Inc./Marine Concepts/Design Concepts (Cape Coral, Fla.) reported that it continues to invest in reverse engineering laser tracker equipment and CNC machining capability, to support customer needs for project design, plug and mold building and parts fabrication. The company is a partner in the Closed Mold Alliance and exhibited a marine hatch cover at its booth made using Light RTM closed mold methods.

Jushi Group Ltd. (Irwindale, Calif.), part of Jushi Group, reportedly the largest fiberglass reinforcement manufacturer in the world, highlighted three new products at the show. Single-end fiberglass roving 312T is designed for high performance pultruded profiles. Its combination of sizing chemistry and single-end manufacture makes it compatible with several resin systems and enables high mechanical properties. Also new were 568FR, fiberglass chopped strands for flame retardant engineering plastics, and 362K, which is fiberglass roving intended for long-fiber reinforced thermoplastics.

Fabricator Litek Composites Corp. (Chino, Calif.) showed its array of filament-wound and hand-layed fiberglass pipe, fittings and accessories for corrosion-resistant apps. With its main factory in Xiamen, China, the company distributes parts through its Chino warehouse facility. Made in accordance with applicable ASTM standards, Litek’s filament-wound pipe, for example, incorporates a resin-rich veil for corrosion resistance and 55-degree helical winding architecture for maximum working strength in high-pressure applications.

Materials Innovation Technologies (MIT, Lake City, S.C.) introduced MIT-RCF, a wet-laid, nonwoven blanket of randomly oriented, intermediate-grade carbon fibers, with areal basis weights of 50 g/m2 to 500 g/m2, which is made from unused prepreg scrap reclaimed from 787 Dreamliner production and currently resold in roll-goods form. MIT is working on providing this material in several varieties, including one that commingles thermoplastic/carbon fibers, stitch-bonded forms from Vectorply Corporation (Phenix City, Ala.) and a prepreg. The carbon fiber prepreg in original form sells for about $35/lb. MIT’s roll-goods product goes for $20/lb. When it is molded with epoxy, it offers a tensile strength of 369 MPa, tensile modulus of 37.6 GPa, flex strength of 556 MPa and flex modulus of 36.4 GPa.

McLube (Aston, Pa.) showed its extensive range of mold release products, including cleaners and mold sealers for composites. MAC-1038 is a relatively new, easy to apply, fast air-curing semi-permanent mold sealer and release that is designed to provide enhanced surface finish and excellent release characteristics for multiple parts. MAC-1038 is compatible with epoxies, phenolics, polyesters and even thermoplastic resins.

National Research Council Canada (Ottawa, Ontario, Canada) was on hand to explain its research and technology mission to develop solutions for automotive and construction sectors using biomaterials derived from Canadian agricultural and forestry biomass. The group showed a range of interesting parts made with low-cost flax and lignin fiber; polymers made with lignin, industrial vegetable oils and bioplastics; expertise in compression, injection and resin transfer molding processes; and the ability to test and collaborate on market strategies for customers.

Nederman LLC (Westland, Mich.), founded in Sweden, is a specialist in plant air pollution control. From dust collection and control for individual pieces of equipment to building-wide centralized air handling systems, as well as recycling and reuse of waste materials, Nederman can ensure that the workplace complies with safety and housekeeping regulations. At the booth: the Nederman 216AE dry vacuum for fine dusts, a portable system that can be set up as either electrically or air-powered. Ideal for the dry dust generated by composites grinding operations, the 216AE can be equipped with a HEPA filter.

Plasticolors Inc. (Ashtabula, Ohio) showed a new pigmented and solvent-free urethane-based gel coat at its booth, developed in a joint venture with PPG Industries Inc. (Cheswick, Pa.), and intended as a tough in-mold coating for wind blades, nacelles and spinners. Thanks to Plasticolors’ additives, the “AGC-10000 Durablade” gel coat exhibits good UV stability and a customizable balance of flex strength and surface hardness.

Precision Quincy (Woodstock, Ill.), manufacturer of a wide range of composite curing ovens, revealed that its new, trademarked PQ2A Commander SCADA software package is nearing release and will be available for order during the second quarter of 2012. This proprietary software suite provides secure, permission-based operator control and monitoring capabilities for an unlimited number of ovens, all networked to one workstation. A user-friendly operator interface displays clear views indicating temperature and vacuum operating conditions. Utilizing a SQL database, the software is positioned to help companies control, research, audit and streamline their oven processes and save those profiles as “recipes” within the program for future use and reference. Technical details on the package will be released soon, says the company.

Technical Fibre Products Inc. (Schenectady, N.Y.), now consolidated in its new location in Schenectady, showed its huge range of technical, wet-laid non-woven mats and veils for composites. Trademarked Tecnofire provides passive intumescent fire protection through the use of exfoliating graphite combined with high-temperature resistant mineral fiber and a binder. When subjected to high heat, a char byproduct is produced that acts as an insulating layer to the underlying materials. Both flexible and rigid product forms are available, including sheets, rolls, narrow coils or cut shapes. Some grades includde aluminum hydroxide (ATH) to further improve fire performance. Also on display were electrically conductive mats and veils for static dissipation, EMI shielding and lightning strike protection.

Thermwood Corp. (Dale, Ind.), manufacturer of both 3- and 5-axis CNC routers used for composites as well as many other industries, described a new line 5-axis machines under development that will be equipped with “high wall enclosures.” The enclosures bring greater dust and particulate control, for a cleaner shop and a higher level or worker safety, and follows an industry trend of increasing use of enclosures as CNC machining becomes more widespread.

TruStone Products (Bluffdale, Utah) displayed its capabilities in cultured marble manufactured by digitally embedding large-format high-resolution images of natural stone into the cast polymer surface, a process the company calls “Photofuzion.” A process involving dye sublimation printing, photofuzion imparts the look of real granite or marble to the product, at a price the company says is comparable to traditional chip and veining techniques employed by other manufacturers.

Wisconsin Oven Corp. (East Troy, Wis.) featured at its booth a complete composite curing oven for prospective customers. With 70 standard oven sizes as well as custom sizes available, in gas-fired, indirect gas-fired or electrical configurations, the company offers temperature certification before shipment, high pressure recirculation blowers, combination airflow arrangements and range of options including chart recorders, digital controllers, pressure transducers and more.

Wm. T. Burnett & Co. (Statesville, N.C.), founded in 1898 as a mattress and cotton batting manufacturer but new to the composites industry, exhibited its products including PolyWeb C — a commingled nonwoven combining chopped fiberglass roving and polypropylene or PET resin fibers that are blended, carded into a batt and needled to form a dense felt in widths up to 130 inches/xxm and glass content up to 50 percent. The material, which can be thermoformed or compression molded and is recyclable, is targeted to automotive, transportation, marine, wind and construction applications. Also on exhibit was PolyWeb, a polypropylene-infused, needle-punched woven fiberglass fabric, suitable for thermoforming panel products.

Syrgis Performance Initiators Inc. (Helena, Ark.) used the show as an opportunity to present its 2012 Syrging Ahead Award for the best customer use of chemistry to advance innovation in boat manufacturing. The award was presented to Tom Broy, president of Independent Boat Builders, Inc. (IBBI) in a ceremony at Syrgis’ booth. The Syrging Ahead Award recognizes Syrgis customers that are capitalizing on chemistry and its offerings to make significant strides in the areas of safety, environmental, quality, process advancement or novel applications. “We’re now in the third year of the Syrging Ahead program, and with each award we’ve seen more and more innovative application of our products and services,” said Andy Harris, Syrgis CEO. Broy says that Syrgis initiators are helping his company build better boats.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Styrene: Issues and implications

The facts (such as they are) behind the furor surrounding this vital crosslinking chemical’s listing in the 12th RoC.

Read MoreSMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreImproving laminates through anisotropy and homogenization

Dr. Stephen Tsai, professor research emeritus in the Department of Aeronautics & Astronautics at Stanford University, discusses the merits of unbalanced (anisotropic) layers in composite laminates.

Read More