Composites at AIA 2017

The ACMA Architectural Division exhibited its 4th annual Composites Pavilion and 2nd annual COMPOSITES CHALLENGE for architectural students.

Composites continue to make inroads in architecture and construction. At the 2017 American Institute of Architects (AIA, Washington, DC, US) exhibition and conference (Apr 27-29, Orlando, FL, US), the American Composites Manufacturers Association (ACMA) Architectural Division exhibited its fourth annual Composites Pavilion, which included Composites Central, a schedule of educational sessions presented by Arch. Div. members, and the second annual COMPOSITES CHALLENGE.

|

|

|

The Composites in Architecture Design Challenge included 1st place winner "MANIFOLD" from Clemson University and 2nd place tie winner "INCUBATOR" from University of Southern California.

COMPOSITES CHALLENGE

A design competition where teams of architectural students develop novel architectural/building components and/or assemblies using composite materials, COMPOSITES CHALLENGE provides an opportunity for tomorrow’s architects to gain not only an education about composites but also hands-on experience in working with them and the potential solutions they can offer.

Coordinated by David Riebe, vice president of Windsor Fiberglass (Burgaw, NC, US), the second annual COMPOSITES CHALLENGE began with a series of student workshops comprising both seminars and hands-on activities in material selection, mechanical properties, production techniques and safety. The first workshop was held Jan. 21 at Clemson University (Clemson, SC, US), attended by around 40 students. Additional workshops were conducted at Kent State University (Kent, OH, US) and the University of Southern California (Los Angeles, CA, US). Roughly 75 students participated overall and showed a strong desire to learn more about designing with composites.

The final 2017 COMPOSITES CHALLENGE included Clemson University, University of Southern California, the University of North Carolina Charlotte (UNCC) and Kent State University. Winners were as follows:

1st Place: Clemson University – “MANIFOLD”

This design deviated from traditional mold-making methods by applying folding techniques that exploit the flexible textile qualities of fiberglass composites to create a complex and structural full-scale column.

2nd Place: TIE – University of Southern California – “INCUBATOR” and University of Southern California – “Plug N Play”

“INCUBATOR” is a proposed construction project, an extension for the university’s Marshall School of Business. The Incubator is a modular structure with composite panels designed to allow daylighting throughout the building to create an open environment for students.

“USC’s second team, “Plug ‘N’ Play,” is also a proposed design for the Marshall School of Business, but in this case for a satellite campus. As the team explains, the site faces challenges of constrained accessibility for construction, poor daylighting, a narrow floorplate and strict building regulations. Composites help overcome these challenges and serve as a viable replacement for steel.

3rd Place: Clemson University – “Double Curvature”

Like Clemson University’s first-place team, the third-place team created a unique column without the use of traditional mold techniques. However, instead of folding, this team used a rotisserie-like jig to weave fibers, creating columns with a “double curvature.”

|

|

|

|

|

Composites Pavilion

A wide variety of products were exhibited in the 2017 Composites Pavilion, showing the breadth of solutions composites can provide for construction and architecture challenges.

Mektech and NexGen Composites displays at AIA. SOURCE: CW

Mektech Composites (Hillsdale, NJ, US) distributes phenolic resins for Georgia-Pacific Chemicals (Atlanta, GA, US). Its display of phenolic composite structures included fiber-reinforced piping used in building sprinkler systems and in the large-diameter piping that feeds the 600,000-gallon memorial waterfall at the World Trade Center site in New York City. Also on display were a variety of composite panels used for blast protection, helicopter pads, interior cladding and myriad other applications, including NexGen Composites panels.

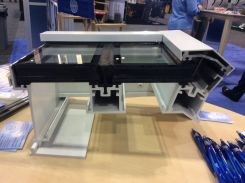

NexGen Composites (Franklin, OH, US) displayed its composite structural insulation panel (SIP) made using fiber-reinforced phenolic skins and various cores, such as the industry standard expanded polystyrene (EPS) foam. This Composite SIP can be used to support structural loads in walls, roofs and floors, offering 50% less joints than traditional wood or metal panels thanks to its 20-ft plus lengths. It is also more corrosion-resistant and energy-efficient than traditional SIPs.

SOURCE: FABS and Windsor Fiberglass

Fresh Air Building Systems (FABS) is a modular and scalable system that reduces airborne toxins/pathogens and generates fresh air in buildings using plants grown in a non-mold producing hydro-/aeroponic system. Composites provide lightweight, corrosion-resistant structural housing modules offering easy assembly and maintenance.

Windsor Fiberglass (Burgaw, NC, US) provides composites design, prototyping, manufacturing and installation for infrastructure components, exterior cladding, interior finishes and building integrated systems.

SOURCE: ReforceTech and Röchling Glastic Composites.

ReforceTech (Luftveien, Norway) in partnership with Owens Corning (Toledo, OH, US) showed concrete reinforced with MiniBars, a patented composite macro fiber mixed directly to enable “pre-reinforced” concrete. It can eliminate the need for steel reinforcement, decreases structure weight and thickness and increases durability and service life.

Röchling Glastic Composites (Cleveland, OH, US) displayed Durostone custom profiles, Durolight thermal break insulation, DuroProtect ballistic panels.

Bestbath in the AIA Composite Pavilion. SOURCE: CW

Bestbath (Caldwell, ID, US) exhibited their composite bath systems that offer the latest in design, safety and accessibility. Composite surrounds are becoming the design of choice in hotels and multi-residence buildings due to their dramatic reduction in maintenance and long lifetime.

Kalwall (Manchester, NH, US) displayed its transparent building systems which are used in building facades, skylights, skyroofs, canopies and walkways. Kreysler & Associates (American Canyon, CA, US) highlighted its recent projects. Also exhibiting, Composites One (Arlington Heights, IL, US) has been a long-time supporter of composites in building and construction, conducting workshops at architecture schools in partnership with Kreysler & Associates and Polynt Composites (Carpentersville, IL, US – previously CCP).

Composites elsewhere on the AIA Expo Floor

Owens Corning is a major presence in the AIA exhibit hall, supplying glass fiber not only into composites but also into batting for insulation and grids used in multi-layer building envelope systems. In fact, there is an issue in establishing what a “composite” is in the architecture/building/construction industry, because that term is used often according to its most fundamental definition — made up of disparate yet discrete parts or elements.

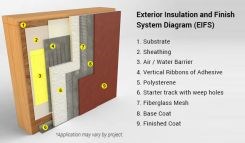

For example, composite metal wall panels may have metal facings and foam core for insulation or honeycomb core for insulation, while exterior insulation and finish systems (EIFS) is a class on non-load bearing building cladding that provides an insulated, water-resistant, finished surface in an “integrated composite system”. The difference between EIFS and the fiber-reinforced composite cladding produced by companies like Kreysler & Associates and Windsor Fiberglass is the ability to impart load-bearing capability, which reduces the need for secondary steel framing to support the panels and the fact that with fiber-reinforced composites, the multi-element, multi-subcontractor system can be reduced to a single element and contractor with potentially dramatic weight, time and project cost savings.

Aluminum composite window (fenestration) systems and EIFS are examples of composites common in construction, named for their multiple elements, which may or may not include fiber-reinforced composites. SOURCE: CW and TriscoServices.com

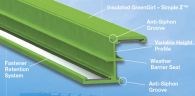

There were also companies on the AIA Expo floor that do use fiber-reinforced composites and are promoting that fact as they grow thanks to the benefits delivered. SMARTci (Allegan, MI, US) supplies a continuous insulation (ci) system that can dramatically reduce the cost to heat and cool a building, plus it meets ASHRAE 90.1-2013 and ASHRAE 160-2009 code, which aluminum systems cannot do without added installation time and cost. Its fiber-reinforced composite pultruded Z-girts do not conduct heat and cold or lead to condensation and mold in the building envelope like metal systems. They’ve also been cleverly designed to save time using standard installation practices.

KONE Corporation (Helsinki, Finland) is a supplier of “smart construction” solutions to the building industry. Its KONE UltraRope for elevator cables uses a pultruded carbon fiber composite core to cut weight vs. traditional steel cables (read more in Jeff Sloan’s blog). “KONE UltraRope allows us to break the rules with respect to travel distance,” says Ken Flannigan, global building information modeling (BIM) solution owner for KONE in Allen, Texas. “We can go up to 1,000 m, which steel ropes cannot do without one or more transfer levels. So we can eliminate this additional shaft and save space.” Flannigan also points out that KONE UltraRope offers greater durability than steel cables.

So what about using more fiber-reinforced composites in the future? “Reducing weight in elevators is about performance,” Flannigan replies. He says he could see extending composites into the elevator car, perhaps, but a lot of simulation and proving out is required to convince justifiably conservative customers. “We see a trend toward urbanization and more vertical development. At the same time, we are a building life cycle partner, so it’s not just about faster, easier installation and taller, more efficient buildings; it’s also about sustainability and maintenance over the long-term.” That, he thinks, is also where fiber-reinforced composites may offer new solutions.

KONE UltraRope uses carbon fiber reinforced plastic (CFRP) to cut weight vs. steel elevator cables and enable higher vertical travel plus reduced energy, installation and maintenance costs.

SOURCE: KONE and constructionglobal.com

Trends Favoring FRP Composites

Living/green/plant walls and systems that bring in more light are part of a strong overall trend to increase wellness in buildings that favors composites. Lightweight is also gaining value as the energy and cost to transport and install materials and systems is being recognized as an area for increased savings and sustainability.

Green walls using plants and systems bringing light and “nature” inside are part of the big “building wellness” trend and favor composites, while metal composite supplier larson is promoting use of aluminum honeycomb-cored panels for lightweight. SOURCE: CW.

Companies interested in supporting the Composite Pavilion at AIA or learning more about the ACMA Architectural Division should contact John Busel at jbusel@acmanet.org.

Related Content

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRaw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More