Composites for builders: Establishing structural foundations

Doors open to composites in residential and light commercial construction, above and below ground.

Since the 2009 update to the International Code Council’s (ICC) International Building Code (IBC), which explicitly permits the use of fiber-reinforced polymer (FRP) in the construction of interior and exterior building structures, architects have taken notice. The building and construction landscape has begun to change, if slowly, in some big ways (see Architectural composites: Rising to new challenges). A similar phenomenon has taken hold in the residential construction realm. Composites have been a fixture in a variety of residential construction amenities: bath fixtures — shower surrounds, bathtubs, hot tubs for decades — and fencing, decking and handrail products are just two of the ubiquitous applications. But until recently, residential structure —the concrete foundation, and the “two-by” wood frame and gypsum board exterior and interior walls — were unassailable. That is no longer the case.

Different, yet not so different

Composite Panel Solutions' (CPS, Eagle River, WI, US) ground-breaking composite foundation wall system, trademarked EPITOME, for residential houses was first written about in this magazine in July 2014, after it was unveiled at the American Institute of Architects Expo in Chicago. There, it won the show’s top innovation award. Much has happened since then. CPS has worked steadily to refine and fully commercialize its patented wall system. The results can be measured today in real-world installations — more than 50 and counting — making CPS perhaps the first fully private enterprise in North America to successfully design and sell a 100% composite solution for a structural application in the residential construction industry.

A key to its success, thus far, is that EPITOME is engineered to present features very familiar to construction personnel accustomed to conventional foundation materials and methods of construction. Its 3 3/8-inch thick by 24-ft long by 9-ft tall wall comprises a foam-cored fiberglass composite panel, including an interior system of reinforcing glass webbing and integral (and US construction-industry standard) 3 5/8-inch wide studs, spaced 16 inches on center along the wall’s length (see photos above). Including the studs, the total wall system thickness is 7 inches.

Glenn Schiffmann, CPS president and EPITOME’s inventor, was aware of the inherent benefits of composites through his father’s work as an airplane designer. As a house component manufacturer, Shiffmann leveraged his background in construction to conceive a foundation wall design that not only incorporated the advantages of composites, but also fit within the conventional, residential house design and building process, making it easy for contractors to understand and install. Compared to a concrete wall, the composite wall will not crack and provides home buyers with an as-installed vapor barrier and an R16.5 insulation value, vs. an R1.5 rating for a concrete wall.

Mike Wallenhorst, director of product management for Ashland Performance Materials (Columbus, OH, US), the supplier of the grade of Modar, the modified acrylic resin used to infuse the wall’s glass laminate, says Shiffmann’s builder experience and its in influence on the design of the EPITOME foundation system is one of the keys to the product’s early success and long-term promise. “Over the years, structural composite housing systems in one form or another have been made and marketed probably a dozen or more times, and they have all mostly failed because they’ve been designed by a composites expert, not a building expert,” Wallenhorst recalls. Although previous composite systems might have provided hosts of benefits, he notes, they fell short in mitigating contractor concerns related to installation, personnel training and selling the systems.

Schiffmann reports that designing a structural insulated panel (SIP) system from composites that would meet building code requirements and be practical to manufacture entailed a lengthy trial-and-error process. The foundation wall’s key structural performance parameter is its ability to meet deflection criteria when back filled with 9 ft/2.74m of the heaviest soil allowed per the building code.

The problem boiled down to designing a cored laminate that could carry those allowable transverse and axial loads and achieve fire, smoke and toxicity (FST) ratings, yet ensure that during infusion, total wet-out of the entire glass schedule was feasible. The final SIP design consists of a 3/16-inch thick outer wall barrier or skin and a 3/16-1/4 inch thick inner barrier made of woven roving supplied by ValuTex Reinforcements Inc. (Washington Court House, OH), a sister company to the manufacturer of the wall, Fiber-Tech Industries Inc., located in the same city.

Owens Corning (Toledo, OH) supplies the glass, an Advantex single-end, SE 1200 Type 30 roving. Sandwiched between the interior and exterior barrier are 4-inch thick by 6-inch long blocks of closed-cell polyurethane foam. Each section of foam is separated by a 1/8-inch gap to accommodate glass webbing that connects the inner and outer walls. The 3 5/8-inch wide studs integrated into the interior wall face on 16-inch centers are foam-cored and nominally 1 5/8 inches thick, like the conventional wood studs they mimic (see photos, above).

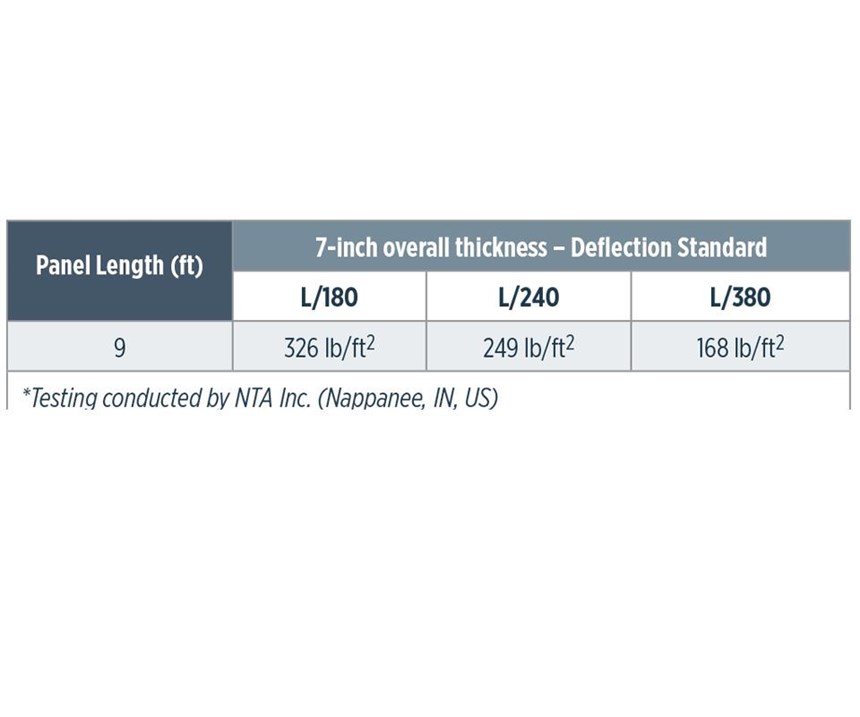

Dan Wojtusik, director of product development at CPS, says the studs serve a two-fold purpose. First, in concert with the internal glass webbing or “mini I-beams” that connect the interior and exterior walls, they are the critical structural features that impart the extreme stiffness and rigidity necessary to withstand the loading of soil on the exterior foundation wall (see Table 1, above). To calculate the allowable deflection for a panel, for example, under the International Building Code’s L/240 deflection standard, one divides the wall length (L = 9 ft X 12 inches = 108 inches) by 240, thus 108 inches/240 = 0.45 inch allowable deflection under 249 lb/ ft2 of load or force.

Wojtusik reports that the 9-ft EPITOME panels’ actual deflection is about 0.187 inch, under full back ll height, or less than half the allowable deflection limit. Wojtusik notes that side-by-side tests of 4-ft wide by 9-ft tall specimens show EPITOME can withstand more than two times the lateral force before failure that can be withstood by an 8-inch thick, 9-ft tall concrete wall reinforced prescriptively with #5 rebar at 40 inches on center, vertically, and 3 ft, 5 ft and 8 ft horizontally.

Second, the studs provide a built-in means to accommodate the piping and electrical conduit, extra insulation and dry wall or other wall finishing material necessary to provide a finished living space. “The stud is the key to our panel system and what makes it work for a builder,” Wojtusik says. “Having the stud integrated into the wall 16 inches on center, the foam insulation, vapor barrier and top plate and seal, all in one, streamlines the installation process.” By contrast, he notes, a builder installing a concrete foundation typically has many additional steps to execute to get to the installation starting point inherent in the EPITOME wall system.

Such construction site utility demanded that the EPITOME SIP wall be both a large and a complex part. Infusing it, then, presented some unique problems that were solved by the SIP’s manufacturer, Fiber-Tech Industries. Wojtusik calls the method now used to manufacture it a “hybrid process” that employs compression and vacuum-assist.

Because of the part’s thickness, and the intricacy of the laminate schedule, Ashland supplies a low-viscosity grade of Modar to wet-out all the glass in the skin and webbing. Additionally, the 1200 SE sizing on the Owens Corning glass roving is formulated to facilitate fast, uniform wet out. Fiber-Tech uses in-house equipment to blend a re-retardant additives package into the resin.

Terry Keegan, Fiber-Tech’s president/COO, reports the company has been in business for 25 years and specializes in making large parts, primarily for the truck transportation market. He says his company manufactures the composite SIP to CPS specifications, noting that despite the part complexity, the process is relatively straightforward. “All the materials are pre-cut and pre-assembled before we start the lay-up process,” Keegan notes.

Builder-friendly system is key

Although CPS’s composite foundation wall system is a radical departure from the conventional concrete wall, in the bigger picture, the product is part of a trend toward panelized construction that has been growing for many years. The trend has been driven, in part, by a construction labor shortage in the US brought on by the 2008 housing crash, which forced many companies out of business. Currently, house component manufacturers build floor, roof and even concrete foundation walls off site, which are then transported to the build site for installation.

One of the most frequent questions contractors ask about EPITOME is how is the wall attached to the foundation footer?

Wojtusik says the answer is in the fact that although the wall is different, the footer is identical to the one used for concrete foundations. First, the wall is placed on the footer and pinned into place along its bottom flange with Simpson L-brackets. The wall is then mechanically attached to the concrete via nails impelled into the concrete by a RAM nail gun. The wall is permanently locked into place when the basement’s concrete floor is poured in a slurry that covers 3-4 inches of the wall’s base. The house flooring system is attached to a traditional wood top plate, which along with the seal, is integrated into the top of the wall. Adjoining walls are connected via pultruded fiberglass connection profiles and mechanical fasteners.

Each 24-ft SIP section can support 600,000 lb (272,155 kg) of downward load, which translates to a maximum allowable house load of 8,900 lb per lineal ft (13,120 kg per lineal meter), with a safety factor of three applied. The composite panels also meet the NFPA 286 room corner burn test and consequently do not need to be covered with a thermal barrier, such as drywall, prior to occupancy, providing the homeowner the flexibility of finishing the basement later.

Because the SIP is manufactured in a standard length, CPS employs a customized panel saw and a continuous “kitting” process to build SIPs to various wall-section lengths. The saw, a PS 1024V Vertical Panel Saw supplied by Midwest Automation (Minneapolis, MN, US), is designed to cut the EPITOME 7-inch thick wall panels in vertical and horizontal directions to accommodate specific wall lengths and heights. The saw also plunge-cuts for window and door openings. If, for example, a foundation wall must be 30 ft in length, says Wojtusik, then two 24-ft panels are connected by pultruded profiles, and the now 48-ft section is cut to 30 ft. The remaining 18-ft section is then connected to another 24-ft section and can be cut to achieve the next required length. This process is repeated until the wall sections for a given basement’s design are produced.

Schiffmann says that from the home-buyer’s perspective, a chief selling point of EPITOME is that the composite wall system provides a well-insulated space and the 16-on-center framing necessary to finish the basement as a comfortable living space. The builders who say “deeper is cheaper,” meaning above-ground finished square-footage is more expensive, are especially correct here. “The EPITOME wall eliminates the dampness, mold and chill associated with a concrete-walled basement and turns it into totally livable space from day one of the move in,” says Schiffmann. He notes, also, that the 7-inch wall provides up to 100 ft2 of additional space compared to a 12-inch thick concrete wall.

Stiff competition

Although it’s still in the early stages of commercialization, the clear-cut performance and practical advantages of the EPITOME wall system are significant in an intensely competitive industry that, by nature, is inherently conservative. CPS has implemented a step-wise strategy for launching, marketing and growing awareness of, and customers for, the product. “As with any new product, you have to start by creating awareness,” says Schiffmann. The company has been active at local, state and national trade shows, such as those organized by the Wisconsin Builder’s Assn. (Madison, WI, US). CPS also has engaged local media; in one case a TV news crew filmed a wall installation. “It’s really been a grassroots effort to get the word out,” he says, noting the company does not have a war chest of money budgeted to run an expensive advertising campaign.

The company selected a pilot market close to its home base in northern Wisconsin for the initial installations, which enables it to monitor the work, and advise and support contractors as needed. The information and feedback they’ve received during the process has, in turn, been used to make improvements in the wall system. The first installations also demonstrated the capabilities of the product — information vital to attracting investors and partners. A key strategy is to create a distribution chain throughout the US Midwest’s “basement belt.” Here, CPS is seeking partners that manufacture house components, such as roof and floor trusses. Component manufacturers, Schiffmann reports, are well suited to distribute and sell the product because they already have relationships with the target customers, such as general contractors and lumber yards, and they also have the materials handling capabilities, such as cranes, necessary to deliver SIPs to build sites. Schiffmann notes, “Our wall system does not add too much overhead to their operation, but it does add another dimension to their product portfolio.” CPS also is open to dealer partners outside the component manufacturing industry who show potential for being a good fit for distribution.

CPS also is benefiting from its relationships with its materials supplier. Greg Shymske, Owens Corning program director, strategic growth – North America, says the company’s partnership with CPS goes beyond supplying glass. “This is an application we strongly believe in,” Shymske says. “We felt that with our integration within the building industry, there was a great opportunity to create synergies and get the word out to the building community, ‘Hey this is a great product and something you really need to look at.’”

Currently, the installed cost of the EPITOME wall system is generally about 20% more than a conventional poured concrete wall with stud framing, top plate and seal, insulation and vapor barrier. is cost differential reportedly shrinks, however, if the concrete wall is similarly insulated as the EPITOME wall, i.e., with continuous foam insulation. However, the EPITOME wall is generally in line with the cost of other foundation systems — for example, insulated concrete forms and pre-cast concrete distributed by a variety of companies. Further, costs can realistically be expected to decline in the future as EPITOME volumes grow and the manufacturing process becomes more efficient. Fiber Tech’s Keegan reports that there has already been at least a 50% improvement in manufacturing the efficiency in the time since the first walls were produced for commercial installation.

Composite wall system aims to push envelope above ground

In the final stages of certification, a new structural composite wall and structural composite sheathing system is targeting not only mainstream residential housing but also light commercial applications. Composite Panel Building Systems’ (CPBS, Robstown, TX, US) Composite Structural Insulated Panel (C-SIP) wall panel system is targeted to go head-to-head with conventional above-foundation structural materials, including wood studs, plywood, and oriented-strand board (OSB) and housewrap in the North American market.

The C-SIP wall panel development process has been ongoing for about five years, and CPBS has already built a fully operational production facility, equipped with two production lines. Each line is capable of producing 10 cured wall panels per hour. The company used its production tooling to manufacture the panels and sheathing tested to a host of material and wall assembly standards, including a third-party quality assurance Label and Listing program, following International Codes Council (ICC) guidelines — the final phase of the product’s development cycle — overseen by the Southwest Research Institute (San Antonio, TX US) Q.C. Program.

The company’s C-SIP system consists of a 4 1/8-inch thick closed-cell, rigid polyurethane foam core sandwiched between two 3/16-inch skins made from biaxial fiberglass mat infused with an iso-polyester thermoset resin, a layup the company refers to as fiber-reinforced thermoset (FRT) to distinguish it from thermoplastics. Total panel dimensions are 4 1/2 inches thick by 47 7/8 inches wide by one of three standard lengths — 8 ft, 1 inch, 9 ft, 1 inch or 10 ft, 1 inch.

The C-SIP system is designed to replace conventional 2x4 or 2x6 wall framing systems that comprise as many as six materials: Conventional wood or metal stud framing, foam or fiberglass insulation, exterior sheathing, vapor retarder, moisture barrier and house wrap. Development of the wall system, as well as the sheathing, has been driven in great measure by a number of new, more stringent house-rating, energy- efficiency standards, such as those of the International Energy Conservation Code (IECC) 2015 Energy Code (required by the US government to be adopted by all US states by June 2016), and the Residential Energy Services Network’s Home Efficiency Rating System (HERS) Index Score (see the Side Story titled, The RESNET Home Efficiency Rating System).

CPBS principal Vince Nastri says the C-SIP system meets and exceeds these standards by integrating glass-reinforced structural skins with continuous polyurethane foam, providing an insulation rating of R-26 that significantly reduces air and water penetration. He notes that houses built with traditional materials can meet these standards, but do so only at the cost of significantly more materials and labor, with a much shorter guaranteed lifetime. “Any wood product absorbs moisture, which makes it susceptible to mold and rot.”

CPBS’s C-SIP is intended to be an alternative to plywood or OSB and housewrap on conventionally framed wood or metal structures, and meets the continuous insulation requirement in the 2015 IECC. The sheathing system comprises an exterior, 3/16-inch FRT skin identical to the skins for C-SIP system, chemically bonded to polyurethane foam insulation. The 47 15/16 inches wide sheathings are manufactured in a thickness of 1-1/8 inches, providing R-6 insulation, and 2 1/8 inches, providing R-12 insulation.

In combination with a traditionally framed 2x4 stud wall with R-15 insulation, the 1 1/8 inches sheathing system delivers a total insulation value of R-21, a level that can be reached with conventional sheathing materials only by the additional space permitted for insulation through the use of more expensive 2x6 stud framing.

The sheathing is attached to the frame using standard dry wall screws and 2 3/4-inch self-tapping screws. The 1/8-inch gap between C-SIP FRT skins is filled with 3M Advanced Materials Division (St. Paul, MN, US) 4000UV Adhesive Sealant, which bonds the skins together, and the entire joint is then sealed with 3M’s 4-inch wide 8067 All Weather Flashing tape. Nastri reports that the sheathing is designed to be used on new houses and as part of exterior energy retrofits on existing properties, a potentially large market. “The US Department of Energy estimates fewer than 20% of the homes built before 1980 are properly insulated and have major air in filtration,” he says.

CPBS manufactures wall panels and sheathing, using composite molds conveyed along a computer-controlled, seven-stage production line. These are, in production sequence order: resin mixing and slurry application, glass-mat application, foaming core station, curing oven, cooling chamber, demolding and mold cleaning. The manufacturing technique is technically an open molding process. On large, mobile at tool surfaces, 4-inch-high aluminum frames are used to set panel boundaries in terms of height and length. The aluminum frames can be adjusted to change panel length. Two molds are used to lay up the FRT skins for each panel. The skin layups are then joined together with a foam core sandwiched between them. One unique aspect of the process is that, unlike many wood or foamed-core SIP production systems, no adhesive is used to bond skins to core, which reportedly can delaminate due to moisture in filtration. Instead, when the mold arrives at the foaming station, the composite skin is still in a gel state. A two-part polyurethane foam is injected into the mold, generating an exotherm that causes the foam to chemically bond to the skin.

One of the key design features of the C-SIP wall is a 0.25-inch wide by 1.5-inch deep FRT channel or groove located between the FRT skin and foam core. The groove runs the entire perimeter of the wall panel, along both front and back sides. The FRT groove in the panels’ bottom and top sides mates with a 4-inch wide composite channel anchored with bolts to the foundation and attaches to the roof trusses with screw fasteners and clips. e materials for the channel and H-stud are manufactured by Bedford Reinforced Plastics (Bedford, PA, US). The C-SIP panels are attached to all the channels with self-tapping fasteners supplied by ITW Buildex (Itasca, IL, US). The 0.25-inch wide channel face groove is filled with 3M’s 4000 UV sealant. The filled joint is, in turn, covered with 3M’s 4-inch wide 8067 All Weather Flashing Tape, sealing over screw heads and bonding to the adhesive sealant creating an air- and water-tight joint over the H-stud connection.

CPBS’ Nastri says the company plans to commercially introduce the wall panel and sheathing systems this spring to three local markets in Texas — San Antonio, Dallas and Austin. He reports the company plans to eventually qualify its wall systems in more than a dozen North American regions, all of which have their own unique standards criteria, such as those for freeze/thaw cycles and wind loadings.

What’s next?

Market-aware design and careful manufacturing engineering have marked the launches and progress, thus far, of two composite structural systems that offer builders the opportunity to re-imagine residential homebuilding. EPITOME has attracted a lot of attention and made a creditable start. Both it and the Composite Structural Insulated Panel are finding an audience through carefully orchestrated, step-wise marketing plans. But will the US construction industry take to materials so radically different from familiar plywood, fir studs, gypsum board and concrete?

Ultimately, it will take some time for the EPTIOME system to realize its potential and reveal the extent to which it will displace conventional materials and alter modes of operation within the construction industry. But Schiffmann says the product’s early success leads him to believe builders and home- buyers are savvy enough to recognize that the composite foundation wall system offers benefits, both during and after installation that are simply not possible with concrete.

In both cases, success in the end will depend on application of the lessons learned as each works closely with contractors and suppliers who use their products and work to narrow the cost gap between composites and legacy materials.

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More