Composites lighten driving simulator dome

A first for its codevelopers, Pagnotta Engineering Inc. (PEI, Exton, PA, US) and JRL Ventures (Cape Coral, FL, US), this low-mass enclosure spawned a new product venture for the pair in research-oriented driving simulation systems.

Pagnotta Engineering Inc. (PEI, Exton, PA, US) and JRL Ventures (Cape Coral, FL, US) each have a long history and reputation for excellence in construction of domed virtual-reality projection enclosures for the flight-simulation industry. Recently the two collaborated on a driving simulator dome, a first for both and a successful study in dome lightweighting.

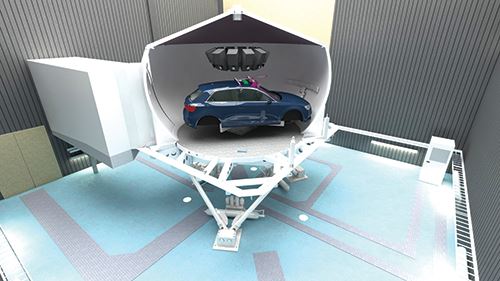

The 5.8m diameter by 4m tall fiber-reinforced plastic (FRP) projection dome — designed by PEI and built by JRL Ventures — is part of the DriverLab driving research simulator, one of four interchangeable, self-contained laboratories that can be mounted on a 6m by 6m six-degrees-of-freedom hydraulic motion platform. Because each dome payload must not exceed the platform’s maximum weight limits, DriverLab had to meet a strict weight target.

DriverLab is part of the Toronto Rehabilitation Institute, University Health Network’s (TRI-UHN, Toronto, Canada) Challenging Environment Assessment Lab (CEAL). CEAL’s motion simulator labs mimic everyday environmental challenges faced by older people and those with disabling injuries or illnesses. DriverLab will be used to assess driving skills and investigate the effects of weather, glare, traffic and devices (e.g., navigation aids, mobile phones) on driver performance, as well as to evaluate the impact of new treatments and remediation technologies developed at TRI.

“Images projected onto screens will surround the driver, who will actually be ‘driving’ a specially modified Audi A3, which will sit on the turntable inside the dome,” explains PEI engineering manager, Alex DiEdwardo. “The simulator will put drivers into different situations and see how they react.” He adds that because this simulator lab includes an actual car, the weight requirement was especially challenging. DriverLab, in fact, will be lowered through floor grates in front of the hospital into CEAL’s underground research facility. Therefore, minimizing crane size, alone, is cost-advantageous. “JRL ... suggested cored construction and vacuum infusion processing to control resin content and keep weight minimized,” he notes.

PEI worked with projection systems developer International Development of Technology (Breda, The Netherlands) to refine the dome’s design and specifications and then generated digital drawings for its roof, floor and 2.7m tall by 2.3m wide sidewall segments. From these, JRL Ventures made the molds for each, using CNC-machined expanded polystyrene (EPS) foam. The shaped EPS was sheathed with fiberglass and resin, then overlaid with syntactic, which was machined to the final dimensions of the dome’s inside surface. Given the small part count, foam molds were practical and saved time and cost but presented a potential lack of vacuum integrity for infusion, a problem for which Diamondback tooling gel coat from Polycryl Corp. (Oakland, TN, US) provided a solution.

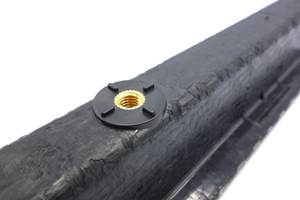

“Because this simulator would operate in the basement of a hospital building, it had to meet building fire codes,” DiEdwardo explains. For that reason, Hawkeye Industries Inc. (Bloomington, CA, US) Duratech vinyl ester in-mold primer was applied over the prepped mold surfaces prior to dry layup, to enable cured parts to be painted with fire-resistant paint. Parts were then layed up as sandwich constructions of (variously) 13 mm to 19 mm thick Airex foam core (3A Composites , Colfax, NC, US), chosen for its fire-retardant properties, between skins of Vectorply Corp. (Phenix City, AL, US) biaxial noncrimp glass fabrics infused with AOC Resins(Collierville, TN, US) Firepel polyester infusion resin, also selected, in part, for its fire-resistant properties.

“Our total weight budget was 3,000 kg, but that included the dome and a steel stanchion,” says DiEdwardo. “The FRP weight ended up being 1,000 kg, including ventilation ducting, so we met the weight requirements without issue and also used cost-effective materials to meet the cost budget.” The dome successfully completed factory acceptance testing by IDT and TRI-UHN in February and, pending timely Audi A3 delivery, will be installed in August.

PEI and IDT are now codeveloping a standard line of driving simulators to serve the needs of research institutes and car manufacturers.

Related Content

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreOwens Corning initiates review of strategic alternatives for glass fiber business

Owens Corning considers alternative options like a potential sale or spin-off as part of its transformative move to strengthen its position in building and construction materials.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More