Continuous fiber thermoplastics are smart for world’s largest appliance manufacturer

Haier uses Covestro CFRTP in Casarte line of “smart” air conditioners

On March 8th, the China Household Electrical Appliances and Consumer Electronics Fair (AWE) opened in Shanghai to an expected 250,000 visitors. As the world’s No. 1 appliance company, Haier’s display of boundary-pushing smart air conditioners was a huge attraction. As was the world’s first air conditioner using continuous fiber reinforced thermoplastic (CFRTP) composites: Haier’s Casarte Tianxi.

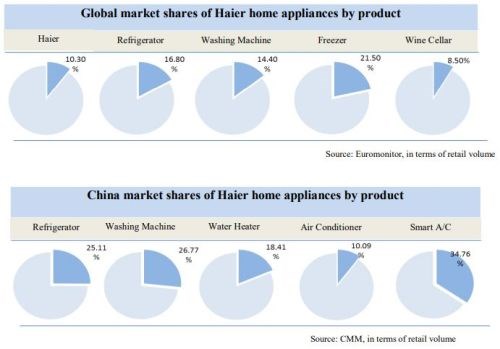

Haier has fashioned its high-end Casarte brand after Italian elegance in design, derived from the Italian “Casa” for home and “Arte” for art. Though Casarte products include refrigerators, washing machines, water heaters and many other appliance types — and have already been incorporated into 1 million households — “smart” air conditioners are a strategic, high-growth market.

The new Casarte Tianxi air conditioner featuring CFRTP composites unveiled at AWE 2018 is part of a growing trend for smart, sensing and efficient high-performance appliances. SOURCE: Sangbe.com

The Casarte Tianxi stands at 1.8 m tall and uses CFRTP in the air conditioner’s twin cylinder housing. It was developed in partnership with Covestro (Leverkeusen, Germany - Pittsburgh, PA, US – Shanghai, China), which won the 2017 European Plastics Innovation Award for CFRTP. The composite material combines unidirectional glass or carbon fiber with polycarbonate (PC) thermoplastic resin in thin tapes. These are cut and stacked to form tailored laminates and then thermoformed with existing tools at high yield rates and short cycle times, according to Michael Schmidt, co-CEO of Covestro CFRTP with David Hartmann.

|

|

SOURCE: Sangbe.com

New material, new design freedom

“Up until now, we have been quite limited in terms of material selection, typically relying on metal to provide the performance and aesthetics that we require,” says Shao Qingru, one of the Color, Material, Finish (CMF) designers in Haier’s Casarte design team. “CFRTP is a very attractive material for us in that it has a natural, unidirectional surface pattern right from the start, unlike metals such as aluminum that requires some combination of finishing processes like sandblasting, brushing and anodizing before it is ready to go into the product. For CFRTP, the finish is all natural and has a beauty to itself.”

In a great article by Yvonne Qian on LinkedIn, Covestro material scientist Yilan Li, who helped to develop the Casarte Tianxi’s use of CFRTP explains the material’s appeal: “Unlike metal, CFRTP is light; unlike plastics, it’s stiff; and unlike thermosets, it’s fast (in cycle times).” She says the material is easy to form, offers design flexibility and has high temperature and impact resistance as well as good strength properties.

Schmidt adds that CFRTP composites “are compatible with a wide range of coatings and decoration processes for designing unique surfaces, logos and other signature details. Laser-etched patterns transfer easily from steel molds.”

Building a value chain, unique partnership

Though the finished product unveiled at AWE makes development look easy, it was anything but. Yvonne Qian’s article explains, “We went from molder to molder to find the right partner and share our material know-how to develop the processing technologies together,” says Yilan Li at Covestro. “It has been lots of trials and fails, but we’re convinced of its market potential and luckily, we’ve got partners who see it the same way.”

The CFRTP team during a molding trial at Yichangtai Plastic Co. Ltd.

SOURCE: Yvonne Qian, LinkedIn.

The Casarte Tianxi housing is molded by Suzhou Yichangtai Plastic Co., Ltd, which has been in the plastics processing industry for over two decades, according to Yvonne Qian. General Manager Chen Jinming has a passion for carbon fiber and his company has been manufacturing 3K woven carbon fabric composites for computer laptop OEMs. “I see huge potential from unidirectional (UD) carbon fiber composites,” he says. “UD allows designers and engineers the basic ability to tune the material to perform differently based on fiber orientation. Aesthetically it looks natural, organic and not overly engineered.”

“As a thermoplastic material, it shortens cycle times and reduces costs compared to thermosets,” Chen continues. “I think the time for thermoplastics has come. Whoever invests in the technologies now will have a competitive advantage in the future.”

Still, Covestro and Suzhou Yichangtai Plastic worked for almost a year to push the Casarte product application to completion. Quoting again from Yvonne Qian’s article: "There were times when processing didn't work out as expected, when logistics were not working in our favor, when some other partners gave up but we just couldn't," says Mike Shi, Industrial Marketing Manager on the CFRTP team. "This is not completely surprising for a new material application, but to witness our team to tackle all the challenges and see beyond the horizon, at times when hope was getting slim, is an immensely powerful experience."

“As a raw material supplier, we don’t just sell our materials and sit back and watch,” says Yilan. “To bring a new class of material to the market, we need to get the value chain to adopt it. If the value chain is not there, we build it.”

Covestro’s relationship with Haier, however, goes back decades to the appliance manufacturer’s founding in 1984 and Covestro’s (then Bayer) supply of raw materials (polyurethane) for thermal insulation used in refrigerators. In October 2017, Covestro and Haier signed a global strategic agreement to expand their partnership to a global scale, aiming to continuously develop advanced products featuring the latest material solutions to address the market demands of the global home appliances industry.

Read the full Covestro press release: “Covestro thermoplastic composites mark entry into consumer appliances industry”.

Future model to be followed?

To say this is a unique partnership is an understatement, not only because of Haier’s top position in the market but also because of the company’s unconventional yet successful business approach. It makes perfect sense that this is the company to push composites forward in household appliances once you look at its character and how it operates.

First, Haier looms large in the market and has firmly staked its place at the upper end, where it delivers value via high-performance products. It shepherds six major brands, including AQUA in Japan, which it acquired via the Panasonic subsidiary Sanyo Electric in 2012; Fisher Paykel in New Zealand, also acquired in 2012; and GE Appliances in the US, which closed in June 2017, as well as its Casarte and Leader brands in China and the Haier brand worldwide. Revenue in 2016 reached RMB 119.07 billion, an increase of 33%, with a profit to shareholders of RMB 5.04 billion, up 17%.

|

|

|

SOURCE: http://www.chinaisgood.com

Second, Haier is smart. It foresaw the potential threat of tariffs years ago, identifying seven "economic protection zones" including North America and the European Union. It set up factories in each one. "We have factories in more than 20 countries, so we have become a localized brand,” said Haier chairman Zhang Ruimin, according to the article, “Haier Boss Looks Far Beyond Appliances” by U.S. New and World Report.

Finally, under Zhang’s leadership, this company with 60,000 employees in 25 countries — including 12,000 from GE Appliances — has seen the danger of stagnation that comes with size and top market position. So Zhang has broken up Haier into a "networked company" of hundreds of independent business units with orders to act like customer-focused startups.

According to the U.S. News and World Report article: "One of their senior managers asked, how are you going to control us?" said Zhang in an interview. "I said, I'm not your boss. I'm not your leader. The leader is one person: The user."

Zhang launched his overhaul of Haier in 2005, splitting structures with thousands of employees into units sometimes as small as a few dozen people to focus on a single appliance or service. Headquarters acts like a venture capital investor. Employees propose new businesses and, if Zhang and other executives like them, receive financial backing. They have to hit financial targets but are left to manage the venture. That network has expanded to include ventures launched with outside entrepreneurs who get money and other support from Haier.

"We don't want just to produce products," said Zhang. "We want to produce creators."

Haier has also tried to speed up product development by using the internet to ask potential customers for suggestions and feedback, an approach taken by Chinese smartphone brands. The company says a new appliance can go from drawing board to market in as little as one year, down from more than three.

So, if composites companies want to follow this model, it is obvious rule-breakers and game-changers are the companies to align with. Of note, the U.S. News and World Report article highlighted two other Chinese companies that are also active in the composites industry, the latter via its robotic arms used in automated fiber placement and 3D printing:

- After buying Volvo Cars in 2012, automaker Geely Holdings left Swedish managers to run the company while they also cooperate on developing cars its Chinese brands might export.

- Midea Group, another Chinese appliance maker, bought one of the leading makers of industrial robots, Germany's Kuka, last year.

Connect-The-Dots

I want to say two words to you: “Thermoplastic tapes”

Thermoplastic composites are also seen as the future for aerospace:

- Toray acquires TenCate Advanced Composites

- Victrex champions thermoplastic composites for aircraft industry

Geely Holdings activity in composites:

- Volvo pioneers 500,000 parts/year with thermoset composites

- Terrafugia acquired by Chinese firm

- Volvo performance brand features carbon fiber bodies

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More