CW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

In 1983, the Airbus plant in Stade, Germany, produced the first aircraft vertical tailplane (VTP) made from carbon fiber-reinforced plastic (CFRP). By 1996, the Stade site, with roughly 1,800 employees, became a composites-only plant. Today, it produces not only all Airbus vertical tails, but also the rear pressure bulkhead for that OEM’s A380, the wing shells for its A400M, and both wing and fuselage shells for its A350 XWB.

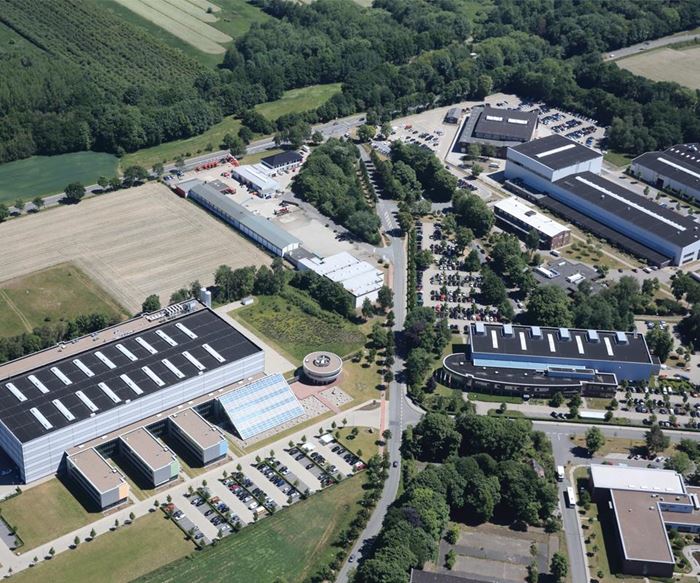

In 2001, Airbus Stade spun off part of its Research & Technology (R&T) group as the Composite Technology Center (CTC), a subsidiary of Airbus Operations GmbH. Now with 42 employees, CTC focuses on the development, production and industrialization of fiber-reinforced composites, and reportedly generates the most patents per capita within the Airbus Group. CTC Stade’s nearest neighbors include the Airbus Stade training workshop, the CFK (German acronym for CFRP) Valley trade association and CFK Nord, Europe’s largest carbon fiber composites R&D center. In such good company, CTC Stade continues to be one of the hotbeds of composites innovation.

Stade, Germany has a reputation as a composites technical development community. CFK Nord, for example, focuses on research of large, complex CFRP components and accommodates many Germany-based partners, including DLR (German Aerospace Center, Braunschweig) and Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM, Bremen), as well as Dow, Olin Epoxy and Airbus Group Innovations (all in Stade) and Premium AEROTEC GmbH (Augsburg).

CTC itself offers space to industry partners. Although CFK Nord and CTC have an aerospace emphasis, both also collaborate significantly with nonaerospace companies. CTC does so in Germany, for example, with three of its major automakers: Volkswagen (Wolfsburg), Daimler (Stuttgart) and BMW (Munich). According to CW’s tour guide and CTC project manager Tassilo Witte, 20% of CTC’s business is outside the aerospace realm. CTC also partners with firms based outside of Germany, including Rolls-Royce (London, UK), Sonaca (Charleroi, Belgium), Sabca (Brussels, Belgium), Toray (Tokyo, Japan) and others.

Reducing and reusing production waste, and end-of-life considerations, have become an integral part of CTC’s research (see "Recycling carbon fiber for structural applications"), as has Industry 4.0 and the industrial internet of things (IoT). CFK Valley Stade Recycling GmbH & Co. KG (Wischhafen, Germany), which recycles carbon fiber via pyrolysis, is a 20-minute drive from Stade. Additionally, CTC has an ongoing development program with composites IoT leader Plataine (Waltham, MA, US, and Tel Aviv, Israel).

As it happens, Plataine’s president, Avner Ben Bassat, and CW take the tour of the CTC facilities together.

Innovation storyline

The tour begins as Witte leads the way in through a doorway halfway along the west side of CTC’s large, open 2400m2 production hall (Fig. 1, above). Passing a piece of the Airbus A350 fuselage, he explains it is a test piece that CTC built for airframe certication testing. “It is a key function of the CTC,” he notes, “we build many of the composites test items, from small-scale coupons to full-scale fuselage shells.”

Witte had cautioned, pre-tour, that there is no ordered storyline to the various developments on the hall floor. “CTC, however, has a strong story,” he points out. CTC, he explains, has four discrete working areas: Production of parts for testing and in support of the various Airbus Operations sites, and then three Innovation Fields.

Within the Airframe & Cabin Structures Innovation Field, CTC explores how to revolutionize long-term aircraft architecture, how to integrate the cabin and the airframe structure, what changes will be needed in composite fuselage design and assembly, etc. “In the Manufacturing Technology Innovation Field, we deal with operational machines and processes,” Witte explains. “For example, we want to make frames from dry fiber instead of prepreg.”

Developments in the Industrial Systems & Assembly Innovation Field look at process layouts in general. Witte says one challenge here is cycle time: “By changing the technology used, can you cut the number of steps and streamline the flow?” A case in point is CTC’s development, together with Airbus, of next-generation vertical tail plane (VTP) structures, where it has iterated through a variety of new materials and processes. “Last year, we assisted in the introduction of flowlines into aircraft production, just as you would see in an automotive production site,” says Witte.

Automating composites production

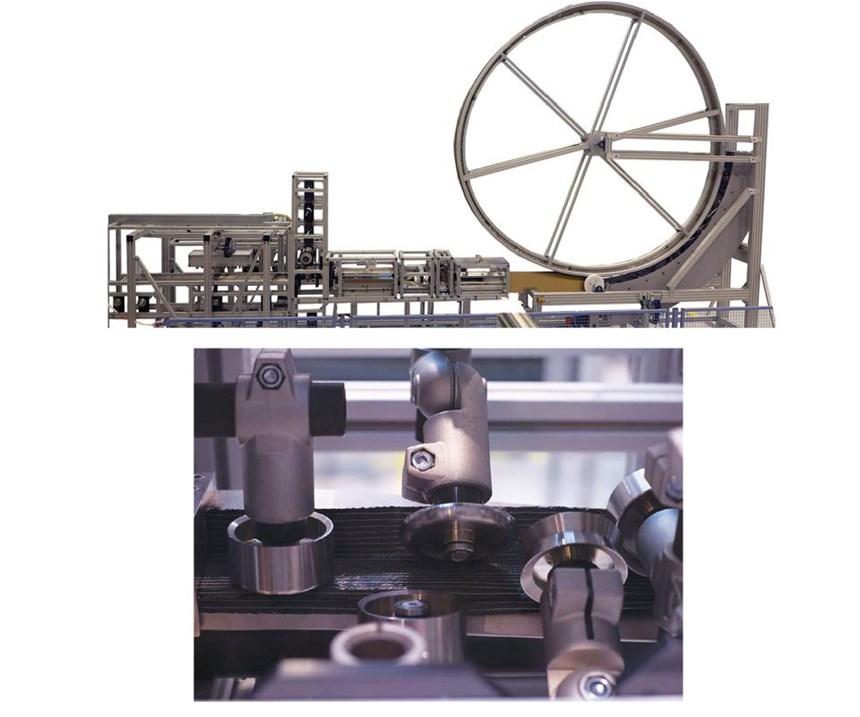

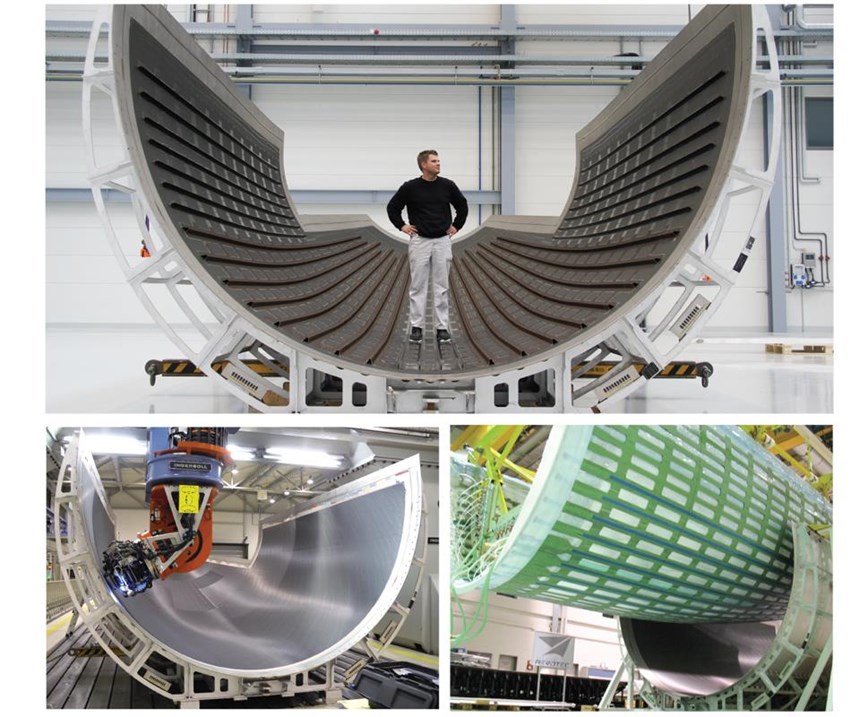

Turning left, the tour halts at a work area dominated by a large machine labeled with Broetje Automation (Rastede, Germany) logos. This automated preform manufacturing system, developed to produce straight and curved sections (Fig. 2, above), is used to fabricate stiffener frames for composite wings, empennage and fuselage sections. The preforms on the line during CW’s tour were Z-profiles, but the system also can produce C-, T- or hat/omega-shaped profiles. Preform production begins with spools of noncrimp fabric and, for flange reinforcement, dry unidirectional tapes. The reinforcements are drawn together into a laminate stack that is compressed (Fig. 2) and heated briefly, melting the binder in the materials. Once tacked, the stack exits the line as an integrated, easy-to-handle preform for resin infusion or resin transfer molding (RTM). Note that the binder in the textiles is derived from a component of epoxy resin, solid at room temperature but liquid at ~120°C. Unlike some thermoplastic binders, it reacts with the epoxy resin, leaving no alien material in the finished laminate, which could affect performance. The large wheel at the end of the line (in Fig. 2) can be used to shape frames to match an Airbus fuselage.

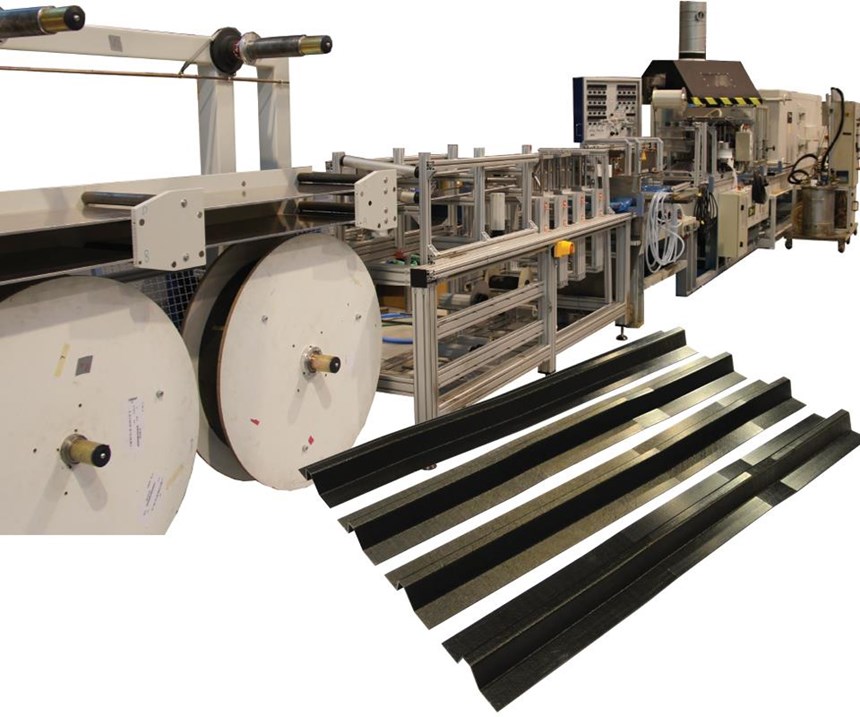

Crossing to the opposite side of the hall, Witte leads the tour to another automated processing line.This one stretches along the building’s east side (Fig. 3). “Lead-time and recurring cost reduction are the main drivers for Airbus R&T,” Witte points out. “We looked at automating stringers with pultrusion, but this restricts you to unidirectional reinforcements.” He notes that RTM as an alternative also is limited, in this case to batch vs. continuous production. “So we developed pultrusion RTM,” Witte explains, “that pulls various tape reinforcements to create a multidirectional laminate stack. Instead of dipping this preform stack through a resin bath, we pull it into an RTM tool. So this is basically infusing on the fly using a tool open at both ends.” During this process, which can run at 14 cm/min, resin is injected (the “resin” part of RTM) at a pressure of at least 1.5 bar to get good flow into the preform. “However, we had to overcome the challenge of the resin being pushed out at both ends of the open tool,” Witte recalls. CTC worked with resin suppliers to develop the solution, which is to have an epoxy resin with a parabolic temperature/viscosity curve. “Thus, at 120°C [the resin] is very thin, but at both room temperature and at 180°C and higher, it is very viscous,” Witte explains. “We cool at the tool entry so the resin is too viscous to flow out, we then heat to cure temp in the middle, and add heat again at the end to make sure resin does not flow out due to injection pressure.” Although the formed stringer exits at 180°C, Witte says the time here is too short to postcure, “So we have an oven that the line moves through to achieve this.”

The pultrusion RTM line can produce omega- and I-beams, “which we cut in half to form two T-stringers,” Witte says. “This is very efficient.” He notes this line also must produce stringers that have a joggle (Fig. 3). A joggle is a joint formed by a notch and a fitted projection. In this case, the stringer is formed to fit into wingskin thickness changes. “This is because there are ply buildups and drops in the A350 wingskin,” Witte explains, “so stringers here must accommodate this change in the surface to which they will be bonded.”

Development of this machine was completed in 2011. “Since then, we have been working on qualication for production,” says Witte. “So it takes 5-10 years to get a new process into airframe production.”

Composites Industry 4.0

Leading the way back to the hall’s west end, Witte takes the tour through a machining room, refrigerated storage for prepreg, a resin mixing room and ammables storage room. The prepreg storage entry is equipped with a radio frequency identication (RFID) receiver. This is because CTC has begun a partnership with Plataine to test and demonstrate the latter’s material and process tracking systems. CTC’s R&D engineer Johannes Born explains: “We will track incoming materials received, as well as prepreg and dry fiber storage areas, collecting material lot and batch information to build a digital thread, but also temperature, out-time and remnant info for prepreg, as well as material type, usage and location information for dry fabrics, in order to help us better manage inventory and waste.” Witte says an example of the latter is a program in development to re-use the 20m remnants left on dry fiber deposition spools during automated layup projects. “We have a very simple jig that allows splicing and rewinding of these ‘leftovers’ to form a full spool that we can now use instead of throwing these materials away.”

CTC will use a mix of RFID, barcodes and other sensors to track the prepreg, dry fabrics, other materials and parts. The idea is to test these systems, identifying issues and best practices, and also explore the full range of possible applications. “We can simulate production at Airbus Bremen, Hamburg or Stade, for example,” says Born, “so we can ‘trial run’ the various process tracking systems for specific Airbus production operations or other customers.” Witte notes that CTC assumes this role quite often, trialing technologies for Airbus, its suppliers and customers before they make an investment.

“One of the issues we’ve already seen is where to position the antennas for RFID sensors,” notes Born. “Carbon fiber and metal tools can interfere with radio signals, and you must also define how to best position the antennas in open space.” Notably, it’s the latter that can be the challenge. “Our production halls are huge, with a 15-20m ceiling height, and RFID range is limited.” He notes, “Normally, you’d simply install the antennas on the ceiling. But if we’d do that, they’d be out of range!”

Plataine’s Ben Bassat adds that testing new sensors at CTC provides feedback from actual composites production situations. For example, Bluetooth low energy (BLE) sensors used in smart phones offer lower cost and increased accuracy, says Ben Bassat, “but we need to see how robust they are with regard to freezer temperatures and maintaining signals throughout handling procedures. Tests so far have been extremely promising.”

CTC also will trial Plataine’s cutting and nesting optimization modules (see “Optimizing composite aerostructures production”). “We can pull up a two-week production cycle from any Airbus location and run it on our in-house set-up of these modules,” says Born, “to see exactly how much effciency could be gained and where we might encounter issues.” And because CTC is an unusual R&T entity in that it also is a fully viable industrial composite manufacturer with knowledge of Airbus production metrics, Born adds, CTC can go the next step and run physical trials as well.

“Where else do you set up an example of a digitally integrated composites manufacturing supply chain? We can do that here, because we have all of the steps: incoming materials, storage, preforming, curing and machining,” he points out. “We can play with these digital optimization systems and test to see how they actually perform.”

“En route to Industry 4.0, you don’t go from zero to full implementation,” Witte adds. “You take steps.” So CTC will begin with temperature and position sensors. “The context of this data within the process is key,” advises Ben Bassatt. “Without the context” — the material’s location, environment and reaction — “you just have a lot of information. Context is what allows our system to start identifying issues and suggesting actions, which will cut waste, improve throughput and reduce labor.”

“We also want to track what happens at the end of the process,” adds Witte, “so that we can improve our use and reuse of materials.” He suggests that the Plataine/CTC partnership also will want to develop new solutions in this area.

Ben Bassatt agrees: “The feedback we get will help us to refine our products more quickly and also develop new products that are already better optimized for the real issues in composites production.” (See also the online Sdide Story to the feature article, titled, "CTC's CEO on Digital Manufacturing.")

Omni-competence for composites

The tour continues around the building’s south end, with quick looks in on a small chemistry lab and a 3D printing lab. In a third room, Witte shows a robotic repair system that Airbus and CTC have been working on for years (see "Aircraft composites repair moves toward maturity"). It uses optical scanning to measure the pre-repair surface, generates a design for scarfing the repair area, controls milling to achieve scarfing and then scans again to generate a repair patch design to match the actual milled surface.

Walking back down the building’s east side, the tour passes a large, high-pressure RTM (HP-RTM) system from KraussMaffei Technologies GmbH (Munich, Germany). As leader of the cross-industry project HD-RTM-LuA, CTC has worked with a variety of partners to adapt the HP-RTM process — originally developed for the auto industry — for aerospace applications, addressing challenges, such as increasing fiber volume to 60% and working with toughened epoxy systems. “We can make CFRP structural parts,” Witte contends, noting, for example, Z-frames, “with 9-minute cycle times.”

The tour continues past an automated cutter from Zünd Systemtechnik AG (Altstätten, Switzerland), three circulating ovens (ranging from 0.4m by 0.4m by 1.5m to 4m by 3m by 3m), and a heated membrane table used for debulking and preforming parts. CTC is also equipped with a Fives Cincinnati (Hebron, KY, US) Viper 1200 automated fiber placement machine for thermoset and thermoplastic materials and a dry fiber deposition machine, comprising a Kuka Robotics (Augsburg, Germany) robot with a CTC-developed deposition head.

Between this area and the pultrusion RTM line is the Assembly Workshop. “We need to be able to reproduce any assembly workstation in Airbus,” says Witte. “So we have this area, which is outfitted to be readily reconfigurable as needed.”

Crossing once again to the building’s west side, and moving slowly toward the tour’s starting point, Witte points out large VTP and glass fiber-reinforced plastic (GFRP) structures, and asks: “How do you monitor laminar flow on an aircraft wing?” Airbus has been developing drag-reducing natural laminar flow (NLF) wing structures for decades and announced in 2015 that it was ready to test a large composite outer wing section, produced by GKN Aerospace (Redditch, UK) and Saab (Stockholm, Sweden).

“You need a unique vantage/view,” Witte continues, “and you can’t just mount a GoPro camera on the wing. So Airbus constructed a camera and fairing system to mount onto an aircraft’s VTP, which we then produced here at the CTC.” Witte concedes that this development was a bit challenging structurally and aerodynamically, but says the final result has worked well.

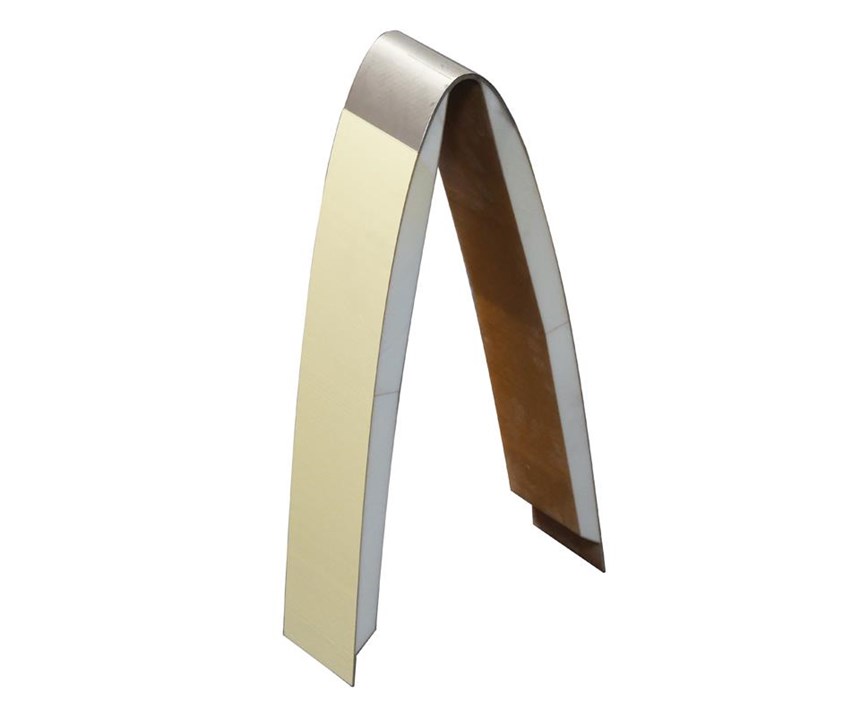

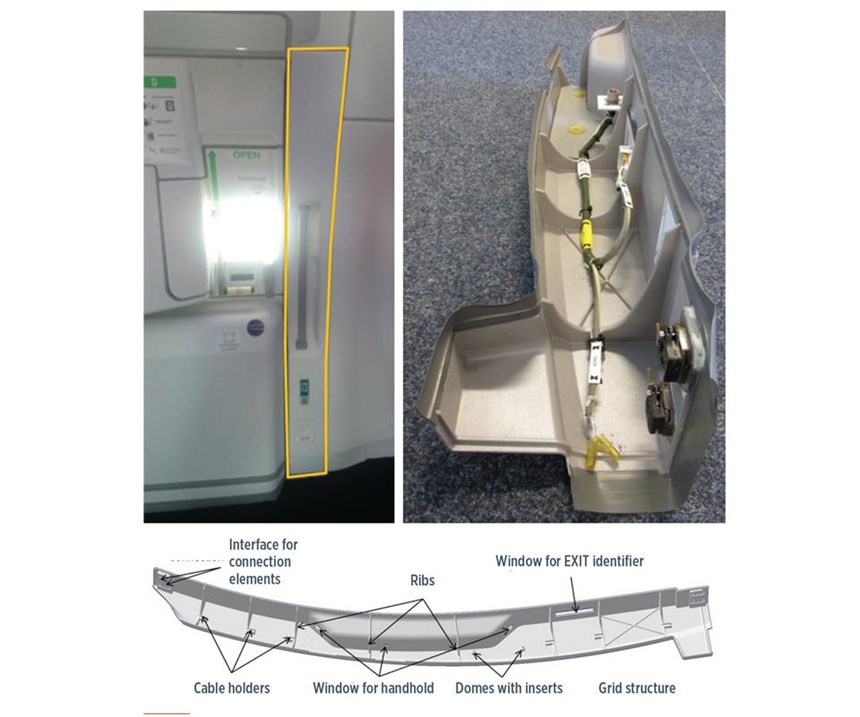

In an adjacent work area, Witte discusses CTC’s ongoing development of a new leading edge for the Airbus A320’s VTP. “The current system is GFRP/honeycomb sandwich,” he explains, “but now we are changing to foam core.” (Fig. 4)

Another new material being qualified is CTC-developed hybrid sheet molding compound (SMC) in glass and carbon fiber SMC with unsaturated polyester resin that meets aircraft interior requirements, enabling shape and function integration while long-fiber prepreg reinforcement handles structural loads. It produces complex parts in short cycle times (see Fig. 7) reduces or eliminates finishing steps and improves buy-to-fly material usage vs. conventional glass fiber/phenolic sandwich construction.

Non-stop innovation

Although the number of capabilities and development projects visible on the production floor is dizzying, they represent a fraction of CTC’s ongoing work, much of it via multi-partner programs (Figs. 5-7). Further, CTC is developing or has achieved automation of almost every operation in the production of composite VTP, wing and fuselage components, and in the case of VTPs, assembly as well.

CTC publications describe its essence as “non-stop innovation,” a description that almost undoubtedly originated with CTC’s CEO Dr. Axel Hermann, who is also CTO of CFK Valley e.V., director of the Faserinstitut Bremen (FIBRE) and part of the team behind the ECOMAT development lab, also in Bremen, Germany. But Hermann also has assembled a very talented and ambitious team. He verbalizes the vision driving much of CTC’s enterprise: “Composites can no longer compete only on performance. They must also offer superior production and sustainability.”

Related Content

Belzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreInha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreThe Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

Read MoreRead Next

Optimizing composite aerostructures production

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More