F1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Design Results:

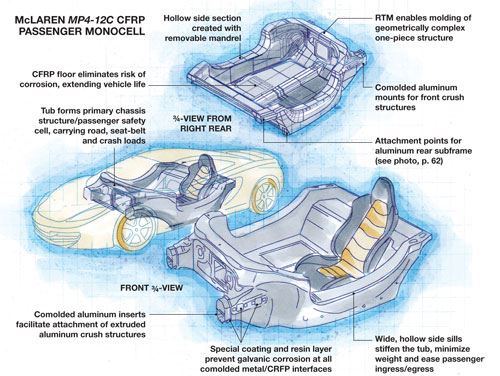

- One-piece carbon-composite passenger cell optimizes overall vehicle stiffness.

- RTM process cuts labor by 90 percent and enables high-volume unit production.

- MonoCell meets all requirements for crashworthiness, stiffness, repair cost reduction, corrosion prevention and passenger ease of access.

Well known for its winning Formula 1 racing cars, McLaren Racing Ltd. (Woking, Surrey, U.K.) was the first race car builder to use carbon fiber-reinforced polymer (CFRP) in Formula 1 cars, a strategy subsequently adopted by all F1 teams. In fact, the company can claim to be the only auto manufacturer that has never used anything else for its cars’ primary structures. McLaren’s pioneering concept of a strong carbon fiber-reinforced driver’s cell, protected by other energy-absorbing structures, has led to a massive improvement in motor racing driver safety over the past two decades.

McLaren Racing’s sister division, McLaren Automotive Ltd., has taken steps to transfer the cell technology to the MP4-12C, the first of a new family of exotic road cars. Although the latter are made by a separate division, the racing and production car manufacturing plants are both housed in the same building, the McLaren Technology Centre, facilitating an inevitable cross-fertilization of ideas. The MP4-12C is the first vehicle in a line that is expected to produce up to 4,000 units per year — a very large number for a supercar. This necessitated the design of composite structures suited to volume production. As a result, McLaren reconsidered the aerospace approach — autoclaved prepreg — historically used by its racing division and many competitors.

Relying on experience

Claudio Santoni, McLaren Automotive’s function group manager for Body Structure, has been responsible for orchestrating this shift in the structural architecture of the new sports car and for making volume production a reality. His background is in the Italian automotive composite industry where, as the head of Composites Structures Development at ATR Group (Colonnella, Italy), he directed the development of ATR’s pioneering approach to a prototype all-carbon composite road car chassis (see “Innovative composite design may replace aluminum chassis,” under "Editor's Picks," at right).

Although Santoni’s history and the fact that McLaren has carbon composites in its DNA might testify otherwise, Santoni has a very pragmatic view of material selection. Under Santoni, McLaren Automotive uses composites only where they bring major benefits and prove to be cost-effective. Santoni still uses metal in many areas where other automotive companies have started to use CFRP. For example, the rear structure, which carries the rear suspension, engine and gearbox, is a spaceframe made from welded aluminum extrusions. Cost and early uncertainty about engine operating temperatures drove this decision. Similarly, the front energy-absorbing tubes are aluminum extrusions that can be replaced inexpensively after a minor impact. And unlike the Aston Martin DBS (see "Gurit CBS for the Aston Martin DBS," under “Editor's Picks”), which makes use of Gurit’s (Newport, Isle of Wight, U.K.) CBS composite panels, most of McLaren’s body panels are aluminum or sheet molding compound (SMC). In particular, the rear quarters and the doors, which have a complex double curvature, are manufactured by Sotira (Change, France) from glass fiber-reinforced SMC.

When it came to the passenger cell, however, CFRP was clearly needed to take the high loads from the varied design requirements. In keeping with the principle of a strong composite driver’s cell developed in McLaren’s racing cars, the new road car has a monolithic CFRP cell structure known officially as a MonoCell, but nicknamed the “tub.”

Protecting the investment

The tub forms the main structure of the car. It takes most of the road loads via a subframe at the front, but it also handles the seat belt loads and, ultimately, the crash loads. The main mechanisms for passenger protection are the previously noted aluminum front and rear crush structures, which crumple to absorb impact energy, leaving the tub undamaged to protect the occupants, even during severe impacts. The success of this design feature has been demonstrated in the crash test program. A single tub has been used in no less than three high-speed impacts, without sustaining significant damage.

The one-piece structure incorporates several hollow sections. Some smaller voids are filled with Rohacell foam from EVONIK Röhm GmbH (Darmstadt, Germany), but the biggest sections are left hollow with removable mandrels. The total volume of these cavities is a massive 120 liters/33 gal (US), keeping tub weight to a mere 176 lb/80 kg.

Although the tub’s immediately apparent function is to carry the main operating loads between the front and rear of the car and protect the passengers, Santoni developed other criteria for its design, including the less obvious requirements of corrosion prevention, overall structural stiffness and ease of access to the passenger compartment.

Corrosion has been a problem in some expensive cars that are made in small numbers, especially when there is a reasonable customer expectation that the expensive new car will survive long enough to become a classic car. McLaren’s use of a composite tub avoids corrosion in the floor and hollow structural sections where metals are most likely to fail.

The hollow sills along the tub sides enhance the stiffness of the tub and, therefore, the car’s overall structure. The sills’ unusual width overcomes one problem common to most supercars, that of getting in and out of a low passenger compartment over a high sill. In the MP4-12C, exiting passengers can sit on the sills as they slide out of the seats.

Although the tub is well protected by crush structures, most areas of the tub are repairable, if necessary. But the design philosophy is that in most moderate frontal accidents, the damage will be limited to the extruded aluminum energy absorbers, the body panels and, possibly, the subframe.

In any case, tub maintenance is expected to be minimal. “The service intervals of modern carbon fiber aircraft have doubled those achieved by aluminium designs,” Santoni points out, noting that this is “a testament to the superior longevity of a carbon-based structure compared to aluminium.”

In line with the company’s policy that carbon fibers are in the vehicle to do a job, not perform cosmetic or marketing functions, McLaren designers resisted the temptation to have CFRP in the MonoCell visible to the customer. The interior of the tub is covered almost entirely with good-quality carpet.

Minting the MonoCell

The greatest challenge was molding the large, complex tub in one piece. The easy design decision would have been to repeat the successful solution used on a previous program, the Mercedes-Benz SLR McLaren Roadster. For the SLR’s tub, an out-of-autoclave prepreg system from Advanced Composites Group Ltd. (ACG, Heanor, Derbyshire, U.K.) was hand layed and cured in an oven. However, only 500 SLRs are produced per annum, a quantity practical for prepreg layup and autoclave processing. Given the need to reduce cost on the MP4-12C and build eight times as many cars each year, McLaren elected to manufacture the MonoCell via resin transfer molding (RTM), using textile preforms. Why abandon a successful, low-risk method in favor of developing one that pushes the boundaries of RTM in both size and complexity? Santoni explains that the manufacturing hours for the new tub were reduced by a factor of 10 compared to those of the prepreg part. Of that time, about half is consumed in making the preform. The remainder is allotted to resin injection, inspection and machining operations.

During the RTM process, aluminum components are comolded with the tub at positions of high load input (see drawing at right). To prevent galvanic corrosion at the interface between carbon fiber materials and aluminum components, the aluminum inserts are prepared with special primers, and the infusion process ensures that there is a thin layer of pure resin between the carbon fibers and the metal parts. Extensive salt spray testing has shown no sign of corrosion.

The RTM resin system is supplied by Huntsman Advanced Materials (The Woodlands, Texas). Preforms are made from high-strength carbon fibers manufactured by Toray Industries (Tokyo, Japan). The preforms are made in two formats — noncrimp fabric (NCF) and woven unidirectional (UD) tape — with a small amount of cross-stitching to hold the assembled reinforcements together. For now, preforms will be assembled by hand from automatically cut layers of NCF and UD material, but McLaren is looking at automating the preform assembly to reduce cost and increase consistency.

Notably, these fiber forms are purchased against a performance specification, without a nominated supplier. Three material suppliers, thus far, have demonstrated that they can meet the McLaren specification.

Outsourcing mass manufacturing

The RTM process and the tooling were developed by McLaren engineers. They have, to date, produced more than 100 tubs, used for structural and crash testing and prototype cars. Production tubs, however, will be molded by Carbo Tech Industries GmbH (Salzburg, Austria). Carbo Tech has installed an automated system that will transfer the mold, with preform in place, to a press for injection and cure. The press can handle two molds simultaneously.

Finished tubs will be incorporated into the car at the McLaren Technology Centre assembly line in a facility currently under construction. Production will begin early in 2011, and the cars will be available in spring of that year.

Editor’s note: McLaren’s Claudio Santoni will deliver a keynote address at the 2010 SPE Automotive Composites Conference & Exhibition (ACCE) in Troy, Mich., Sept. 15-16.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreRead Next

Innovative Composite Design May Replace Aluminum Chassis

It's been called the automotive engineer's dream material. Able to assume any shape while delivering stiffness, strength and light weight, carbon fiber has been the material of choice for years in structural components and stylishly aerodynamic exterior panels on race cars and exotic supercars costing more th

Read MoreGurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More