Fast-build construction with composites

A Brazilian modular wall system that can deliver affordable homes and schools in days is exported to meet global needs, including for refugee resettlement.

MVC Plásticos began in 1989 as an engineering plastics fabricator for the automotive industry. Based in the city of São José dos Pinhais, in the Brazilian state of Paraná, it expanded, opening manufacturing locations in Catalão (GO), Camaçari (BA) and Maceió (AL). Now a composites manufacturer, it supplies a variety of products into not only the automotive but also the wind energy, agribusiness, general industrial and construction markets.

“Our philosophy is to use composites to replace traditional materials,” notes Erivelto Mussio, MVC’s development manager of building products. Using a variety of fibers, resins and other materials, it has expanded its processing repertoire to include continuous lamination, vacuum forming, thermoplastic extrusion, resin transfer molding, resin infusion and pultrusion.

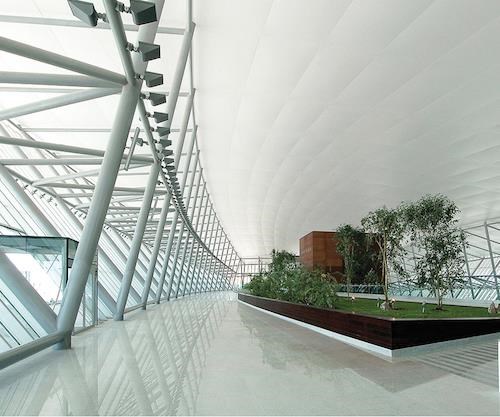

It is in the field of construction that MVC Plasticos has begun to make its international mark. Building on its experience with continuous lamination and pultrusion, the company began development of its MVC Wall System in 2003. It is a modular construction system based on industrialized production of composite sandwich panels made from fiberglass-reinforced composite sheets and insulating core, connected at corners and other joints by pultruded profiles. “The original idea was to build affordable houses,” explains Mussio. But soon it became clear there were opportunities in many other types of construction, including banks and schools. MVC also has supplied specialty panels for the ceiling of the award-winning Carrasco International Airport in Montevideo, Uruguay.

The selling point? Although onsite construction time depends upon the building type and size, once a foundation (typically a concrete slab) is completed, Mussio says assembly and finishing of the wall system proceeds with comparatively “Lego-like” simplicity, taking only 12-15 days for small buildings (e.g., a 70m2 house) and 60-120 days for larger, more complex structures (e.g., a 3,100m2 school), or roughly 30% of what conventional construction would require. That’s not to suggest, however, that MVC Plasticos sells temporary structures. All MVC Wall System components are designed for a minimum 50-year service life.

No surprise, then, that the company is negotiating expansion throughout South America and is completing certification as far away as Germany to export its modular housing for resettlement of Syrian refugees. “The need is so large,” Mussio points out. “We are not yet sure how many houses will be built, but there is potential for thousands.”

Intensive industrial manufacturing

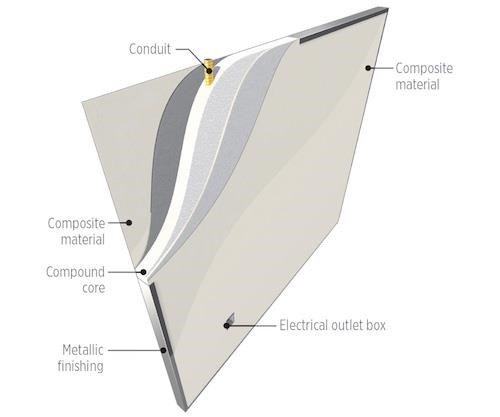

Fast onsite build of the MVC Wall System is possible because most of the construction is completed in the MVC factory. “We have industrial production of the building components,” explains Mussio. These include pultruded structural profiles — such as columns and beams — and then the “blade” sandwich panels for walls and ceilings. The walls are rolled out complete with window and door openings and with electrical installations inside (Fig. 1). When the components arrive at the building site, they only need to be assembled, and then painted and finished with plumbing and light fixtures, floor coverings, etc.

The panels use glass fiber-reinforced polyester resin facesheets, produced via continuous lamination (Step 3) and include an orthophthalic gel coat surface resistant to ultraviolet radiation.

The glass fiber rovings used in pultrusions (Roving 366) and panel facings (Roving ME 3050) are supplied by Owens Corning Fiberglass A.S. LTDA (Rio Claro, SP, Brazil). The orthophthalic polyester resin — which includes alumina trihydrate to meet fire resistance requirements — is sourced from Reichhold Do Brasil LTDA (São Paulo). The composite facesheets are continuously laminated, cut and then bonded to EPS (expanded polystyrene) or polyisocyanurate (polyiso) foam cores with polyurethane adhesive in low-pressure vacuum presses (Step 4). Before they are bonded between the facesheets, the foam core slabs are routered and pre- fitted with the electrical conduit and outlet boxes.

EPS foam offers an insulation value (heat resistance) of R-4 to R-5, while polyiso foam is rated as R-6 for 1-inch thickness (the higher the value, the greater the insulation; see Learn More located under "Editor's Picks" on the top right). Although it is not used in the MVC Wall System, fiberglass batting is rated at R-3. “For the climate in Brazil, where we don’t have a cold winter, EPS is sufficient,” Mussio notes, adding that “for Europe, however, polyiso foam is needed. We don’t change the thickness of the panels, but instead change the insulation capacity through the type and density of foam.” He says MVC prefers to keep the panel thickness standardized because they are connected using pultruded profiles, which are made to specific measurements. To change the panel thicknesses — the walls are typically 10 cm and the ceilings are 5 cm — would require a cascade of tooling changes for the pultrusions.

Finished panels are routed for windows and doors (Step 5) and outfitted with adhesively bonded edge profiles. All components are then labeled and grouped appropriately for shipment to building sites.

Reduced onsite assembly

At the building site, MVC’s customer, the construction contractor, takes over. Base fixation profiles are bonded to the concrete foundation using structural epoxy adhesive (Step 6) and then affixed with corrosion-resistant, stainless steel self-tapping screws. Panels are then adhesively bonded into the base profiles and a silane-based sealant used in shipbuilding is applied to ensure moisture resistance. To bear overhead roof-and-beam loads and join panels at junctions and corners, pultruded vertical columns are installed at each panel’s vertical sides, adhesively bonded and screwed into base profiles and panel edges (Step 7). Pultruded cover pieces are used to conceal the panel/column seams as well as any additional piping or conduit installed by the builder. Next, horizontal pultruded beams are placed on the tops of the wall panels, to form a load-bearing structural frame to which roof joists can be attached (Step 8).

In larger, more complex structures, galvanized steel profiles are used in place of selected pultruded profiles to increase load-bearing capability. Mussio also notes that there are cases (e.g., roofing structures) in which standards are still lacking for composites. “So conventional materials are used here to speed structural calculations,” he adds. From there, commercially available doors and windows are fitted into the factory-engineered openings, and the building is finished using conventional materials (Step 9).

Modular design controls cost

Because the MVC Wall System is based on modules, MVC Plasticos can mass-produce standard components, yet combine these to provide a wide range of design alternatives to meet specific building project needs. “The engineering process is longer than the construction process,” Mussio points out, “so the cost would be too high if we had to engineer a new construction for every building. Also, we need enough quantity of the same structures for industrial production, so this requires some standardization.”

MVC Plasticos also has developed standard structural models: three for schools in Brazil and four options for schools in Argentina, including two- (208m2), six- (850m2) and 12-classroom (3,100m2) models and daycare centers (1,060m2). The school buildings contain administration/office space, kitchen, class- rooms, bathrooms and a covered play area, with the larger models also including warehouse and storage rooms, service areas and dressing rooms.

Of course, there are always projects that demand something different. Mussio says changing the color of the resins in the pultruded profiles and panel surface sheets is possible, and although panels are normally kept within a 3.5m width and 12m length to accommodate transportation by container or truck, panel dimensions can be varied. For example, MVC supplied narrower 2.5m wide by 7.5m long panels to form the lower (inner) surface of the parachute-shaped Carrasco International Airport terminal. Further, the 22,000m2 of panels did not differ in appearance, but were split between three designs, according to wind resistance requirements. Areas inside the terminal at the structure’s center were not exposed to wind, but those in outer regions were, and had to resist additional loading.

Ensuring that system components can meet the structural requirements of each project was MVC Plasticos’ greatest challenge, says Mussio. “Developing the MVC Wall System was very difficult because there were no internationally accepted standards to make the static calculations for the pultruded structural system components,” he explains. “We needed proof of our construction methods and the load-bearing capabilities.” Additionally, composites are designed with different compositions based on the types of fibers, reinforcement patterns, resins and processes used. “So there are many, many possibilities to produce the same structural profile,” says Mussio. “This variation in materials produces large variations in strength and stiffness, the structural properties. To overcome this challenge, we had to make many prototypes, physi-ally test them and then provide not only our structural calculations, but also all of our own test data.”

But the extensive development has become a plus. “Now we are benefitting,” he explains, “because, for Germany, we can send all of our test data and they can verify our calculations and structural performance, and compare that with other systems.” This also was key in the selection process used by Brazil’s National Program to Restructure and Equip the Public School System (PROINFÂNCIA). “Our constructions were verified as technically superior to projects using conventional construction systems,” says Mussio.

MVC has made a significant investment in order to ensure its system is readily usable by the construction industry worldwide, including a dedicated design and development center, an extensive and well-equipped material and physical testing laboratory and a staff of civil and structural engineers. The latter have enabled development of all the fixation and installation details, which are explained and illustrated by the necessary drawings and reference documents for each project.

Advantage for the underserved

MVC’s combination of superior performance and speed of delivery is a definite advantage, and not one typically enjoyed by the students and families who benefit from these composite construction projects. But the value is undeniable. For example, in 2011-2012, the MVC Wall System was used to rebuild 35 schools in 12 municipalities that had been destroyed by heavy rains in the Brazilian state of Alagoas. Two-room schools were completed in less than 30 days and six-room schools in less than 60 days — note that the concrete foundations alone typically required 15 and 30 days, respectively. Thus, students were able to resume their classroom education more quickly than with conventional construction, and enjoy more comfort, quality and safety vs. temporary, trailer-type units.

Although many of its housing projects comprise 20 units or fewer, the MVC Wall System nevertheless has been used in more than 280,000m2 of built area, including large residential developments, such as the 436-house project in the city of Japeri, in Rio de Janeiro, completed in December 2013. Built as part of the My House My Life Program for low-income families, each of the project’s 37.8m2 houses includes two bedrooms, a living area, kitchen, bathroom and laundry/ service area. In 2014, MVC also initiated construction of a large 250-house project in the city of Igrejinha.

In 2016, the company formed a strategic partnership with Argentinian resin manufacturer PLAQUIMET (Buenos Aires). According to PLAQUIMET director Eric Engstfeld, production from a new manu- facturing plant there is slated to begin in 2017, with the goal of providing new alternatives that will speed commercial/ residential development there and accelerate its participation in the global trend toward energy-efficient and sustainable construction.

As part of its forward-focused strategy, MVC Plasticos continues to develop new designs. The O.BOX, a clever one-room module, can be a cost-effective retail/ service space or modules can be combined to provide aesthetic yet affordable options for first-time homeowners. The CONEKTA+ concept uses stackable composite units to achieve more sustain- able multi-story housing.

In the middle of the 20th Century, “Casa de plástico” was heralded by futurists around the world. MVC Plasticos’ 21st Century achievements in materials, process and an economical approach has finally realized that future, one made possible by fiber-reinforced plastics.

Related Content

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More