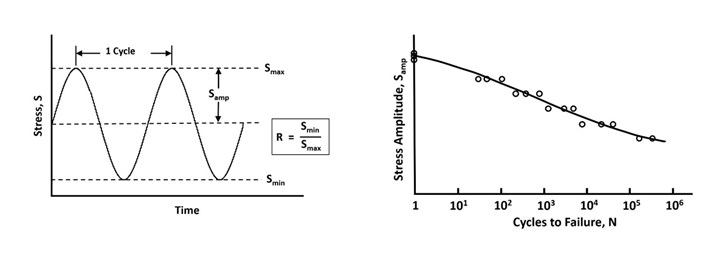

Fig. 1. Standard method used for displaying fatigue test results. 1a (right) shows standard fatigue testing terminology, and 1b. (left) depicts an S-N diagram. Photo Credit: Dan Adams

Fatigue testing may be performed at multiple points during the design of a composite structure. A focus on small-specimen level fatigue test methods, however, suggests a need for continued test method standardization.

Fatigue testing involves the application of cyclic loading to a test specimen or a structure. Unlike monotonic tests in which loading increases until failure, the applied load is cycled between prescribed maximum and minimum levels until a fatigue failure occurs, or until the predetermined number of loading cycles have been applied. If failure does not occur within the prescribed number of loading cycles — ranging from thousands to millions depending on the application of interest — the test result is referred to as a run-out.

Results from multiple fatigue tests, performed using several different cyclic stress levels, typically are plotted as the amplitude of the alternating stress, Samp, (Fig 1a) versus the number of cycles to failure, N, and are commonly referred to as an S-N diagram (Fig. 1b). All of the fatigue tests included in the plot are performed using the same ratio of minimum stress to maximum stress within a loading cycle, referred to as the cyclic stress ratio, or R. For tension-tension fatigue testing, R-ratios of R = 0.1 are commonly used, whereas for reversed tension-compression fatigue tests, an R-ratio of R = -1.0 is typical. Fatigue testing is also used to investigate stiffness and strength reductions in composite materials and structures resulting from prior cyclic loading. For these determinations, testing is performed under cyclic loading for a prescribed number of cycles, followed by monotonic loading to failure.

Fatigue testing may be performed at multiple points during the design of a composite structure, featuring different sizes and complexities of test articles. Small-specimen and simple, element-level tests are used to determine the fatigue behavior of composite materials and laminates, as well as to investigate the sensitivity of environmental conditions, stress concentrations and existing damage to fatigue performance. Larger and more complex structural element, subcomponent and full-scale structure fatigue tests are also commonly performed as part of a building block approach for composite design1. Since higher-level fatigue testing varies greatly across a broad spectrum of applications, I will focus this column on small-specimen level fatigue test methods for composite materials that tend to be common to many applications.

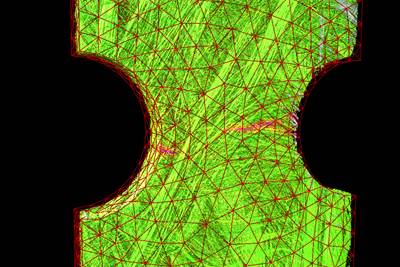

In contrast to metal fatigue, in which failure may be produced by a single crack or a small number of cracks that coalesce, the formation and propagation of fatigue damage in polymer matrix composites (PMC) is more complex, often involving multiple types of damage. In multidirectional composite laminates, fatigue damage often initiates as matrix cracking, followed by the formation and growth of delaminations, and eventually fiber fracture. Therefore, it’s common to perform fatigue tests using multidirectional laminates intended for use in the composite structure rather than unidirectional (0° or 90°) laminates. Additionally, the types of specimen-level fatigue tests as well as the fatigue loading (such as tension-tension versus tension-compression) is often guided by the primary loadings expected for the particular application of interest.

Compared to the relatively large number of standardized mechanical tests for PMC under monotonic loading, currently there are relatively few that focus on fatigue loading. ASTM D34792 was first standardized in 1996 for tension-tension fatigue testing. The tabbed specimen geometries specified are the same as for monotonic tension loading in ASTM D30393 and the scope is limited to constant-amplitude fatigue testing under either load or strain control. The primary test result is the fatigue life (number of cycles to failure) corresponding to the specific stress amplitude, R-ratio and environmental condition used in testing.

Somewhat surprisingly, there are no current standardized test methods for fatigue testing of PMC under compression or in-plane shear loading. Although not standardized to date, many test methods used for monotonic testing of PMC may also be used for fatigue testing with relatively minor modifications. Under some conditions, additional constraints are required as part of the test fixturing to prevent the test specimen from moving relative to supports or loading surfaces. Additionally, cyclic loading can produce wear and premature failure at specimen loading surfaces. Finally, for reversed tension-compression fatigue testing, special attention is required to eliminate “slack” in the load train of the test machine when passing through zero force.

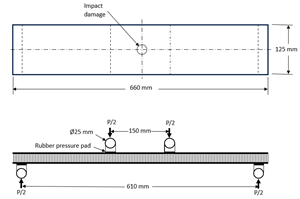

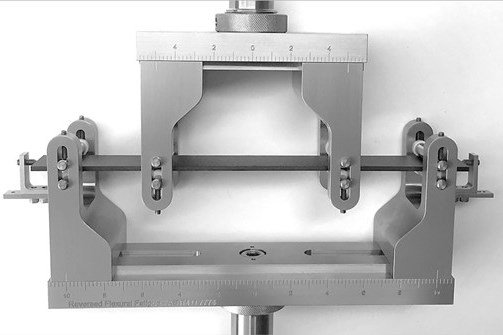

Flexural fatigue testing is among the most common specimen-level fatigue test performed with composites, and among the simplest to perform. Currently, there is no standardized method for flexural fatigue testing of PMC. However, ASTM D77744, which focuses on fully reversed (R = -1) flexural fatigue testing of unreinforced plastics may be used as a guide for when applying the existing ASTM D72645 flexure test method for PMC to flexural fatigue. Specialized test fixturing is required that includes additional restraints as well as dual loading rollers for reversed loading (Fig 2). Additionally, an ASTM standard practice is currently under development for short-beam fatigue testing of PMCs, providing guidance for modifying the monotonic short beam strength test method in ASTM D23446 for constant-amplitude cyclic loading.

Fig. 2. Flexural fatigue test configuration for composites. Photo Credit: Wyoming Test Fixtures

Within the ASTM D30.05 Subcommittee on Structural Test Methods, two standard practices have been developed for fatigue testing. The first, ASTM D76157, provides guidance for performing open-hole or “notched” testing of composite laminates under cyclic tension or compression loading. The open-hole test specimens and test fixturing used in cyclic testing are identical to those prescribed for monotonic tension (ASTM 57668) or compression (ASTM D64849) loading. The second standard practice, ASTM D687310, addresses the bearing fatigue response of composites, using the four bearing test procedures (Procedures A-D) described in ASTM D596111 for monotonic loading. Special considerations for cyclic bearing testing include the removal of fiber-matrix debris resulting from damage associated with hole elongation. In these, as well as other composite fatigue test methods, the static strength reduction associated with fatigue damage may be determined by discontinuing cyclic loading following the prescribed number of fatigue cycles and subsequently loading monotonically to failure.

Finally, specimen-level fatigue testing may be performed to investigate the propagation of existing damage under fatigue loading. ASTM D611512 provides a test methodology to determine the number of fatigue cycles required for the onset of delamination growth under constant amplitude Mode I (opening) cyclic loading using the Double Cantilever Beam (DCB) specimen. Additionally, while not standardized to date, cyclic Compression-After-Impact (CAI) testing may be performed following the test methodology provided in ASTM D713713 to assess the effects of pre-existing impact damage on the fatigue resistance of composite laminates.

References

1CMH-17 Composite Materials Handbook Volume 3 – Revision G, Chapter 4: Building Block Approach For Composite Structures, SAE International, 2012.

2ASTM D3479/D3479M-19, “Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2019 (originally published in 1976).

3ASTM D3039/D3039M-17, “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2017 (originally published in 1971).

4ASTM D7774-17, “Standard Test Method for Flexural Fatigue Properties of Plastics,” ASTM International (W. Conshohocken, PA, US), 2017 (originally published in 2012).

5 ASTM D7264/D7264M-15, “Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2015 (originally published in 2006).

6ASTM D2344/D2344M-16, “Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates,” ASTM International (W. Conshohocken, PA, US), 2016 (originally published in 1965).

7 ASTM D7615/D7615M-19, “Standard Practice for Open-Hole Fatigue Response of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2019 (originally published in 2011).

8ASTM D5766/D5766M-18, “Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2018 (originally published in1995).

9ASTM D6484/D6484M–20, “Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2020 (originally published in 1999).

10ASTM D6873/D6873M-19, “Standard Practice for Bearing Fatigue Response of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2019 (originally published in 2003).

11ASTM D5961/D5961M-17, “Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2017 (originally published in 1996).

12ASTM D6115-19, “Standard Test Method for Mode I Fatigue Delamination Growth Onset of Unidirectional Fiber-Reinforced Polymer Matrix Composites,” ASTM International (W. Conshohocken, PA, US), 2019 (originally published in 1997).

13ASTM D7137/D7137M-17, “Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates,” ASTM International (W. Conshohocken, PA.), 2017 (originally published 2005).

Related Content

Multi-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

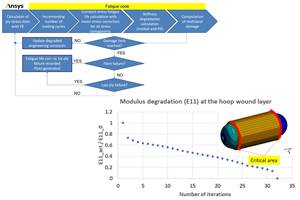

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read MoreNotched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read MoreRead Next

Reversed loading flexural fatigue

Dr. Donald F. Adams, owner and president of Wyoming Test Fixtures (Salt Lake City, Utah) discusses reverse loading flexural fatigue testing and fixture design.

Read MorePart 2: Applying CT scan data analysis and visualization to composites

Advanced CT-scan analyses can offer deep insight into challenges faced when examining novel composites and hybrid material behavior or performing quality and certification testing. Part two of a two-part series.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More