Floating turbines promise off-grid power sources

A novel hybrid floating wind turbine/offshore oil platform concept exemplifies the potential for composites to enable emission-free supply of power in remote locations.

Although most announced projects are still in their formative stages, those using floating offshore wind turbines offers several, well documented and significant advantages when compared with offshore turbines that must be anchored to the seabed. Most obvious is that floating turbines can be stationed in deeper waters, which exponentially expands the geographical possibilities for siting wind farms where winds are consistent and wind velocities desirable. Floating turbines also are less costly to manufacture and install than the fixed, offshore variety.

First to float

Earlier this year, Statoil ASA’s (Stavenger, Norway) Hywind Pilot Park, located 25 km off the northeast coast of Scotland in 90-120m of water, became the first full-scale, commercial offshore floating wind turbine farm. The project comprises five Siemens SWT-6.0-154, 6 MW turbines, mounted to a “spar” type foundation (essentially a long tube filled with ballast). The turbines feature 154m rotor span, featuring three 75m-long fiberglass-reinforced epoxy blades, cast in one piece via Siemens’ proprietary IntegralBlade manufacturing process. Each turbine has a massive swept area of 18,600m2, which can produce 15-30 GWh of electricity per year, enough to power about 20,000 homes, with a projected operational life of 20 years.

Other floating wind turbine projects, commercial and demonstration, are currently in development In Europe, Japan and North America (read CW’s report on the launch of University of Maine’s one-eighth-scale floating wind turbine) and are variously scheduled for deployment in the 2018-2020 timeframe.

Although these vary in design, the floating wind turbine systems mentioned thus far are similar in that they are designed to supply power to a commercial grid. But a new Joint Industry Project (JIP) project, first reported by CW Blog in a May 2016 CW, proposes a twist on the technology, using floating wind turbines as a power source for pressurized injection of water into injection wells in offshore oil fields. The concept, as envisioned, is groundbreaking in that it will attempt to build not only a floating turbine, but an autonomous, floating turbine/well injection system, designed for off-the-grid, remotely controlled, on-demand operations in offshore oil fields. DNV GL (Oslo, Norway) is leading the project, termed WIN-WIN (for WINd-powered Water INjection), with a group of participating cross-functional partners that includes ExxonMobil (Irving, TX, US), ENI Norge AS (Sandnes, Norway) and the Oslo-based Norwegian Research Council.

Water injection plays a role, onshore and off, in recovery of oil at aging reservoirs. These so-called “tail end” fields have seen their natural pressure, which made oil extraction easy, decline. Without water injection, in fact, producers would recover only 30-35% of a field’s oil. Injection wells, often located many miles from host production wells, are drilled into the oil reservoir to enable the oil company to pump water in under pressure. The injected water increases pressure in the reservoir, and moves the oil in the direction of the well head for recovery.

In offshore injection, however, the electric pump that pressurizes the water and other platform-based equipment is usually far from a commercial power grid and must be powered by gasoline-fueled generators. The use of wind-powered water injection affords several benefits, including ready access to power and decreased CO2 emissions from generator-powered wells. DNV GL conducted a study of the 25 largest oilfields in the North Sea and found that tail-end fields, not surprisingly, produced the most emissions, because they require the largest injection volumes to maintain. The study found that some of the oldest fields produce three to four times the CO2 per unit of oil recovered as fields in earlier stages of production.

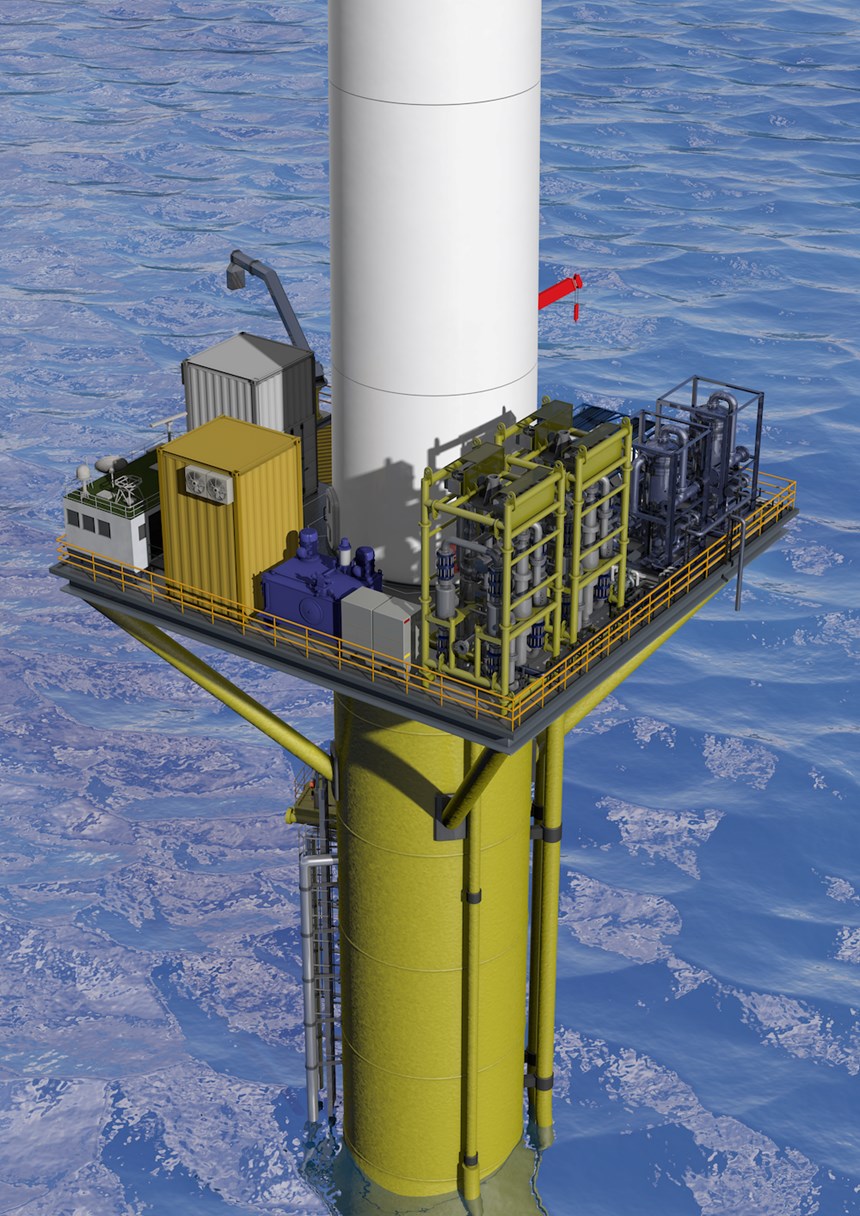

Announced at the 2016 Offshore Technology Conference, the JIP’s first phase entailed a detailed “in use case” study of the concept’s feasibility, both technical and commercial, using site-specific data from an actual injection well platform located in the North Sea, 30 km from the host well and 30 km from the coast at a depth of 200m. The reservoir consists of two injection wells with a target injection rate of 44,000 barrels of water a day. The study considered the use of a 6-MW turbine mounted on a spar foundation — identical to the foundation on the turbines at the Hywind Pilot Project — equipped with two 2-MW injection pumps capable of pumping a maximum of 80,000 barrels of water per day. Simulations based on historical wind data at the site confirm the system is capable of injecting volumes that exceed the target of approximately 50,000 barrels.

The hypothetical turbine considered in the study is also fitted with a platform mounted to the tower near its base, accommodating the following equipment: hydraulic power unit, mechanical package, water filtration unit, two injection pumps, chemical storage and injection unit, battery bank and davit crane (see second photo, above). Seawater is pumped to the platform via lift pumps, filtered to 50 micron, treated with chemicals and injected. Drawing on simulations and knowledge of “microgrid” applications in other industries, the use case study projects with a high level of confidence that a similar electrical system could be used to facilitate controlled startup and shut-down of the system, while ensuring the matchup of power demand and power supply during operation.

Testing and specifying this electrical system is the objective of Phase 2 of the JIP, currently in progress, according to Johan Slätte, DNV GL’s project manager for the program. Because injection volumes are dependent on the conditions for a specific reservoir, the project team will be investigating the use of different pumps, injection equipment and treatment systems, which can operate under a wide range of conditions. The detailed functionality of a battery system, required to power communication and turbine control equipment during periods of low wind conditions, will also be defined in this phase. The stability of the microgrid supporting the process will be tested in this phase.

While the project has yet to consider materials for manufacturing turbine blades, tower and foundation, glass-reinforced composites’ track record for fixed, and, now with the installation of Statoil’s Hywind Pilot Park wind farm, floating offshore turbines (similar in design to the turbine proposed for the in-use case study), will clearly make the materials the prime candidate for these applications as the project moves forward. “For floating wind, and offshore wind in general, new materials that reduce weight and lower the cost level are of great interest, whether it’s the turbine tower, blades or mooring system for a floating unit,” Slätte says.

Overall, the Phase 1 study found, floating turbines designed to power offshore water injection are projected to have higher operational costs, but lower capital costs, resulting in an overall 20% costs savings over a 20-year lifetime. Additionally, the cost comparison tilts in favor of wind-powered injection the further the injection well is located from the production platform, and also for tail-end wells with decreasing recovery rates. Indeed, as recovery rates decline for older wells, producers often find it more cost-effective to shut them down rather than continue to run water injection operations from remote platforms. “We see floating wind as an enabler to increase recovery rates and extend the life of wells,” says Slätte.

While the immediate, near-term objective is to apply floating turbines to offshore oil injection wells, one can readily imagine the concept, in both floating and fixed configurations, could be modified to supply off-the-grid power for other applications in remote regions worldwide. The remote power concept, like the floating turbine technology itself, bears following as it develops.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreHow composites have become a necessity

Composites used to be one of many material options across industries and applications, but that's not the case anymore.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More