Formulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

The direct, or inline-compounding (ILC), process has been a major boon to thermoplastic composites during the past decade. Direct processing has driven significant growth in the use of such materials — particularly glass-reinforced polypropylene (PP) — at the expense of both sheet-form chopped glass-mat thermoplastic (GMT) and pelletized long-fiber thermoplastic (LFT) technologies, even when the latter feature higher-temperature engineering-resin matrices.

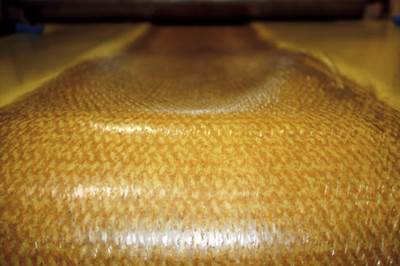

As ILC technology for Direct-LFT (D-LFT, a/k/a LFT-D in Europe) has continued to evolve, machinery OEMs and researchers have found ways to incorporate not only longer glass fibers, but also continuous-fiber rovings and woven fabrics that boost mechanical performance, thus enabling D-LFT to compete directly with high-performance fabric-reinforced GMT and conventional sheet-molding compound (SMC). Resin suppliers have contributed to the expansion of D-LFT technology via polyamide (PA) and other higher temperature engineering resins. Although there is no doubt that innovation will continue on the thermoplastics side of the market, ILC is now being re-applied on the thermoset side — where, it could be argued, direct compounding began — to form SMC in a new way that brings unique benefits to processors and end-users.

BMC and SMC

If SMC could be said to have a cousin, it would be bulk-molding compound (BMC). The resemblance is striking; both technologies have thermosetting matrices and both are available with unsaturated polyester and vinyl ester matrices (BMC also comes with a phenolic matrix). Each is reinforced with chopped glass and uses mineral fillers. SMC typically has a higher percentage of glass reinforcement and is stiffer; BMC typically has higher mineral-filler loadings, so it is less costly. Both offer good dimensional stability and have decent impact strength, broad chemical resistance and good thermomechanical properties. Further, they can be painted, plated or stained and can achieve a Class A automotive finish. Each is produced as a semifinished product prior to molding, but here the differences emerge: BMC is produced in bulk, or log, form; and SMC is produced as calendered sheet stock that is subsequently cut to specific sizes. SMC is generally compression molded, and BMC can be shaped via injection, compression or transfer molding — processes that are capable of supporting medium- to high-volume production. Both materials typically reduce mass by 20 to 30 percent vs. comparable aluminum or steel parts, and they do so at lower tooling costs. Both are used in automotive and ground transportation (automobiles, pickups and heavy trucks), building/construction, gardening/agricultural and appliance/electrical-component applications.

Although most SMC and BMC in North America and Europe are generally purchased in standard formulations from compounders, BMC does offer processors that have the right equipment the opportunity to compound at the press shortly before molding — an option used in China. ILC gives processors a broader opportunity to tailor reinforcements, fillers and other additives to achieve the properties required for a given application. For high-volume applications, this can be less costly than purchasing precompounded materials. The ability to adjust the formulation on the fly also saves time and grants more control to the processor. These attributes make it easier for molders to create custom compounds for short production runs and allows them to modify properties more quickly during preliminary part development and/or when field data for commercial products indicate that properties need adjustment.

Direct-SMC

Now, thanks to the work of a European consortium, it is possible to combine the lower cost and formulation flexibility of BMC with the higher mechanical performance of SMC in a hybrid process called Direct-SMC (D-SMC, also called direct-strand molding compound). Developed by research house Fraunhofer Institute for Chemical Technology (Fraunhofer ICT, Pfinztal, Germany), machinery OEM Dieffenbacher GmbH + Co. KG (Eppingen, Germany) and resin supplier DSM Composite Resins AG (Schaffhausen, Switzerland), the process eliminates the need for the several-day maturation period required with conventional SMC and reduces production delays. With D-SMC, the commonly lengthy interval between compounding raw ingredients and demolding finished parts can be shortened to minutes.

“By design, D-SMC is a continuous (not batch) process in which raw materials are compounded into sheets that are cut into charges and then molded directly afterwards,” says Tobias Potyra, operations manager at the new Fraunhofer Project Centre at Western University (FPC@Western, London, Ontario, Canada) and one of the original researchers on the project at Fraunhofer ICT. “Owing to the closed-loop nature of this system, it is possible to guarantee a high and constant level of quality that is more challenging to achieve with conventional SMC.”

He notes that scrap is reduced, which has a positive effect on component costs. Because it is no longer necessary to wait days for material to mature, the time and cost of storing precompounded materials are eliminated. Processors also gain greater flexibility in terms of raw material selection and get close to real-time control over formulation changes. “And with the closed machine path used to produce D-SMC,” Potyra adds, “styrene emissions can be better controlled, making it easier to comply with health and safety regulations.”

Erik Reuther, new business development manager – automotive at DSM Composite Resins, outlines the team’s challenge: “SMC is formulated with up to a dozen raw materials, so a major point we needed to address as we began designing a ‘just-in-time’ SMC process was how to dose and compound the material accurately and consistently.”

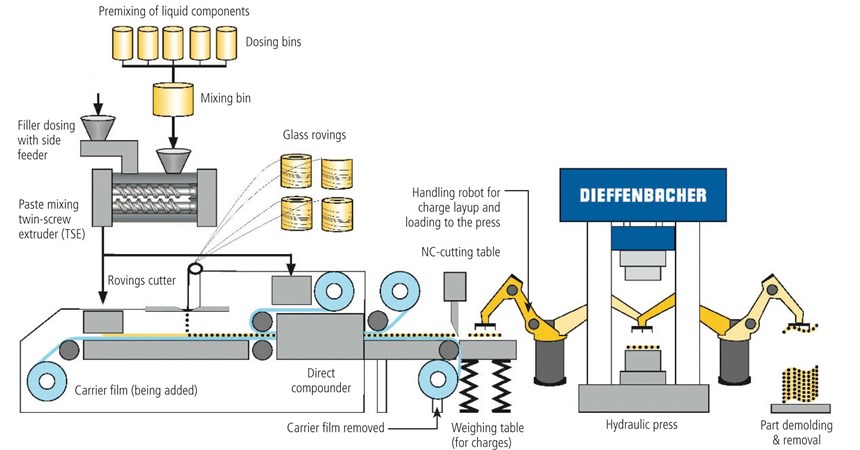

The process in its current form, therefore, begins with automated dosing and mixing of the liquid raw materials (e.g., unsaturated polyester resin, low-profile additive and peroxides). Then, solid ingredients (release and thickening agents, and fillers, such as calcium carbonate) are added gravimetrically from a side feeder. The resulting mixture is fed into a Dieffenbacher twin-screw extruder, which forces liquid and solid components together to form a homogeneous compound. Next, the mixture is split into two equal streams and transferred into doctor boxes on the direct compounder. There, continuous glass rovings are fed, cut and spread between the top and bottom layers of the resin-filler paste as they come in from the doctor boxes. To achieve consistent dispersion, the sandwich of paste and fiber strands is run through a degassing and impregnation roller section, where fiber wetout takes place. The impregnated material then moves through a rapid-maturation zone where, in a temperature-controlled environment, the chemical thickening of the D-SMC material takes place within a few minutes. At the end of the zone, the D-SMC is cooled to ambient temperature and moves directly onto the automated numerically controlled (NC) cutting table, where it is cut into the required charge pattern and subsequently laid up to form the charge load for the compression molding process. A robot picks up the charges and places them in the open tool of a compression-molding press, which then closes and molds the part. Depending on the sheet width, throughput and material formulation, the complete cycle — from compounding through molding — can take as little as 15 minutes.

Dieffenbacher has developed its new dedicated SMC Directline equipment to automate ILC during the D-SMC process. The first pilot line has been in operation at Fraunhofer ICT for more than a year, where it has produced material for numerous formulation and molding trials. Characterization shows that the D-SMC material is very similar to conventional SMC, except that the compound consistency is greater because the twin-screw extruders are more effective than the dissolver process typically used to produce conventional SMC.

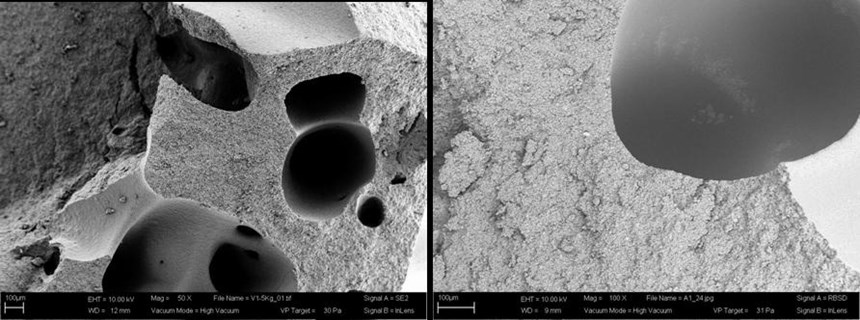

Microscopy verifies that D-SMC compounds have fewer air inclusions and achieve finer and more homogeneous filler dispersion than conventional SMC. Consortium members continue to evaluate and report the effects of machine and formulation changes on the technology. A second SMC Directline system has been commissioned for FPC@Western, which is set to open in the third quarter of 2012 for North American composites development.

Direct benefits

“The main idea of direct technology for thermoset compression-molded composite parts was to establish a continuous, integrated process chain with seamless process control, from raw material to ready-molded parts,” recalls Dieffenbacher’s technical director, Matthias Graf. “From the fiber-reinforced thermoplastics side, we have seen the shift from precompounded pellets and GMT sheet stock to a direct processing technology. Since SMC can be considered to be a thermoset type of LFT-D, the idea was to follow a similar process.” Although Dieffenbacher is one of the inventors of D-LFT and sells ILC units that are coupled to its large compression presses to compound and mold D-LFT parts sequentially, Graf shares the credit for D-SMC’s success, thus far, with its consortium partners. “We formed a team representing the best in each field of machinery, resin chemistry and research to get D-SMC to work,” he points out. “No single company could have achieved this alone.”

Capable of a high degree of automation, the continuous D-SMC process is fulfilling its promise. It provides full line control, visualization and documentation from compounding through molding. Moreover, it saves considerable energy and costs by eliminating previous transport and storage steps; it provides reproducible fiber impregnation and consistent, Class-A quality; and it allows individual recipes to be optimized for all ingredients. Notably, D-SMC also provides opportunities to increase fiber-volume fractions for more demanding applications. Given these benefits, D-SMC offers not only a greater degree of formulation freedom for compression-molded composites but also provides opportunities for SMC molders to fight for market share lost to D-LFT composites during the past decade.

Intriguingly, DSM’s Reuther concludes, “GMT is quite similar to SMC and, therefore, a development to a direct process like D-LFT is considered as a logical next step.” If a direct-GMT process is in the works, then the composites industry could see another game-changer.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Bio-based fillers: Reducing SMC mass

The Bio-Lite Technical Center of Excellence at the National Composites Center (Dayton, Ohio) is developing sheet molding compound (SMC) recipes capable of yielding finished parts with specific gravity as low as 1.2.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)