FRP challenges conventional frame-and-drywall construction

A multinational builder and a machinery manufacturer join forces to bring an automated composite panel molding system to the residential construction market.

Although composites are more costly than wood, concrete and aluminum, their greater strength-to-weight ratio, superior thermal properties and humidity-, corrosion- and insect-resistance can provide contractors in the building construction industry and their customers with benefits that are difficult to match. In applications such as decking, in fact, the appeal of a long-lived, maintenance-free product have so outweighed conventional alternatives that consumers are willing to pay the composites’ cost surcharge. However, despite the performance premium, composites have generally not been able to overcome the price-point disparity in mainstream applications, such as house/building framing and wall construction, where contractors bid almost exclusively on cost. However, an automated manufacturing system geared for this market might change that cost/benefit equation.

A manufacturer of composites fabricating equipment and systems, Magnum Venus Products (MVP, Kent, WA, US) has designed, built and installed a composite-panel manufacturing system for a multinational (but unidentified) construction and fabrication company in Brazil. The custom-built manufacturing cell reportedly has narrowed the cost differential between composites and lumber, drywall and other conventional materials in the housing market, and has the potential to narrow the gap further. The fabricator customer is using the equipment to make large, 12m by 2.5m composite sandwich panels, which are then CNC-machined into various interior and exterior wall sections and components; in the process, the fabricator incorporates windows, doors and other features, and packages the parts into kits for onsite assembly that requires small construction crews and little heavy equipment.

Joe Jansen, MVP’s advanced equipment sales engineer, says the machinery maker partnered with its customers and construction companies to design and build a complete manufacturing cell for commercial production of the composite building system. “We work with our customers to make ideas commercially viable,” says Jansen.

“The big challenge for this project, and for composites trying to compete in mainstream residential construction in general, is how to make composites competitive with wood by using automation,” says Jansen. The system evolved from a process MVP first used to make equipment for the manufacture of boat hulls. The most significant modifications to the process entailed the development of a method and equipment to change it from a batch process into a continuous, assembly line-like method for high-volume production.

To make the panels, a stock roll of 0°/90° biaxial glass fabric is fed vertically into a set of impregnator metering rolls, positioned above a mold. For exterior walls, the mold is first fitted with a finished, textured facing sheet. The spacing between the metering rolls is precisely controlled, as is the feed rate of epoxy pumped onto the rolls. The epoxy is specially formulated with a catalyst and flame and smoke retardants. The wetted fabric is then fed into the bottom mold, which is moving at the same rate on a stationary friction-wheel conveyor. When the entire length of the mold has been layed up with glass, a polyurethane foam core is laid atop the wetted glass and the mold direction is reversed. It again passes under the impregnator metering rolls, which lay down a second, or, in the case of an exterior wall, the interior layer, of glass/epoxy laminate. As the length of the mold passes under the impregnator the second time, the glass fabric is cut and a top mold is affixed to the bottom. The top mold is vacuum bagged with an overlap at the seam between the two molds. Top and bottom molds are both heated to a range of 71°C to 82°C, and a vacuum is applied as the mold is transferred by a large gantry-based robot into the line’s curing section for the approximately 25-minute curing cycle.

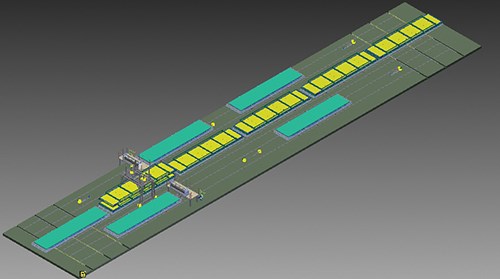

The panel production facility is equipped with a 5-station curing line that is fed by two resin impregnator production units, one on each side of the curing line (see schematic at left). The two impregnator units lay up a new panel every 12 minutes, but layup is staggered so that one cured panel is produced every 6 minutes. After a panel is layed up, it’s transferred by the gantry robot to an adjacent curing station on the curing line. There, the top mold half is placed atop the panel and 6 minutes later, when the next panel is layed up and ready, the curing line shuttles forward the length of one curing station; the gantry robot, meanwhile, travels to the end of the curing line, retrieves the top mold half from the first fully cured panel, and transfers that mold half back to be placed on the most recently layed-up panel. This configuration yields an assembly line-like multiplication of efficiency: While the overall cure time for a single panel is 25 minutes, when the line is fully loaded and multiple panels are cycling through, the effective panel cycle time is 6 minutes.

The cured panels are about 76 mm thick with a laminate layer that is ~60% glass fiber. After CNC machining, the exposed foam edges of window sills, doors and interior walls are encapsulated with moldings. The prefabricated elements are delivered to the construction site on pallets, stacked in the correct sequence for the construction process on conventional concrete foundations.

Pultruded U-channels are anchored around the perimeter of the foundation and the construction process starts with the installation of two corner walls. Walls are bonded into the U-channels and to each other with a proprietary adhesive over the entire length of the wall/joint. The composite panels also comprise the roof, to which a waterproof roofing mastic is applied, eliminating the time and cost of installing roofing tiles. The entire construction process requires about one-third less time than conventional construction, according to the kit manufacturer, and the finished house is waterproof, fire resistant and certified to withstand wind speeds up to 250 kmh. The composite housing manufacturer sells the kits to licensed contractors and is aiming to achieve an international presence, including in North America. Contractors have already completed the construction of several subdivisions made up entirely of the composite houses.

Jansen says the impregnator units provide significantly improved repeatability from part to part, compared to hand layup methods, a factor that is critical to ensuring the efficiency and cost savings associated with the construction process. “Earlier composite building systems were manufactured by highly manual means,” he says. “Automation is the key factor helping this system gain commercial acceptance.”

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More