Google shoots the moon

Google Lunar XPRIZE contenders turn to space- and launch-friendly composites.

The XPRIZE Foundation (Culver City, CA, US) was conceived to encourage private industry and its innovators to attempt grand challenges that might otherwise go unmet. Its existence and its monetary incentives came to high-profile notice in the composites industry when Burt Rutan and his Scaled Composites LLC (Mojave, CA, US) teams’ SpaceShipOne became the first private manned spacecraft to exceed an altitude of 328,000 ft twice within the span of a 14-day period and, by doing so, claimed the US$10 million dollar Ansari X-Prize.

The foundation’s approach is competitive, and it rewards its grand prize to only one participating team, allowing it to claim a (usually substantial) sum of money if it is the first to complete the prize requirements. Since Rutan’s team reached the edge of space with the aid of composites, the prize stakes have been raised considerably. A new prize, another high-profile funding source and a more distant destination are now in prize contenders’ sights.

Moon 2.0

In 2007, Google (Mountain View, CA, US) and the XPRIZE Foundation announced the Google Lunar XPRIZE (GLXP), also dubbed Moon 2.0, “to incentivize space entrepreneurs to create a new era of affordable access to the Moon and beyond while inspiring the next generation of scientists, engineers, and explorers.” That according to Chanda Gonzales, prize lead for GLXP.

Registrations closed at the end of 2010, and, as noted above, only non-governmental teams were eligible to apply. But to qualify as grand prize contenders, competing teams were required to receive verification from the XPRIZE foundation that the latter had confirmed that the participant did, indeed, have a signed launch contract by the end of 2016. Further, to win the US$20 million grand prize, the winning team must be the first to complete the following (see The emerging commercial space industry: Google’s Lunar XPRIZE):

1. Initiate launch to the Moon by Dec. 31, 2017 (previous requirement was for landing on the moon by Dec. 31, 2017);

2. Place a spacecraft on the Moon's surface that travels at least 500m over the moon’s surface, and

3. Transmit high definition video and images back to Earth.

There also is a combined US$5.25 million in intermediate Milestone Prizes (as noted below), awarded to teams for progress made here on Earth in preparation for their GLXP missions.

Contender teams turn to composites

The competitors are well along in their planning and execution. Five teams qualified for the GLXP competition by Dec. 31, 2016. SpaceIL (Jerusalem, Israel), Moon Express (Cape Canaveral, FL, US), Synergy Moon International (San Francisco, CA, US); Hakuto (Osaka, Japan) and Team Indus in Bengaluru (aka Bangalore, Karnataka, India). Each has turned to composites for some part of their mission spacecraft or launch vehicle.

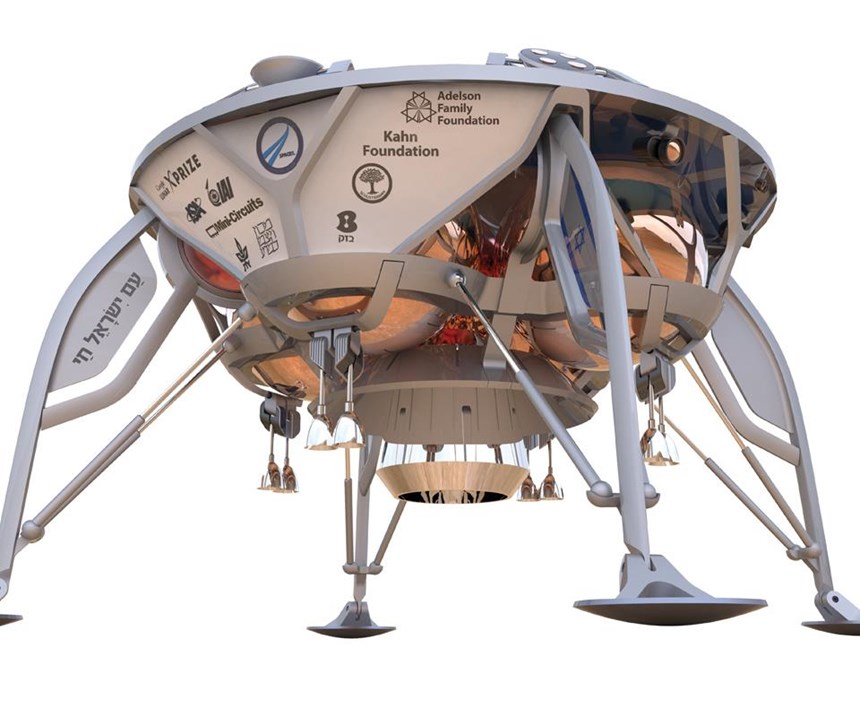

SpaceIL was the first team to receive verification of its launch contract from XPRIZE, having signed for a launch on the Falcon 9 rocket from Space Exploration Technologies (SpaceX, Hawthorne, CA, US), brokered through Spaceflight Inc., a co-manifesting service in Seattle, WA, US. Launch is planned for late 2017, from Vandenberg Air Force Base, CA.

A variety of carbon fiber/epoxy prepregs and aluminum are used in its tentatively named Sparrow spacecraft’s struts, landing gears and in its High Gain antenna support structure. The company is leveraging knowledge of nano-satellite technologies developed by unnamed experts in Israel to build a relatively small and smart unmanned spacecraft. The craft will soft-land on the moon and then re-ignite its engines to hop the required 500m, then send high-definition video and images back to earth. (Soft landing refers to touchdown on the moon or other surface in a controlled and gradual way that avoids damage to the landing vehicle or its contents.) In addition to the GLXP requirements, the Sparrow will explore the enigmatic magnetic field of the Moon, and toward that end, will carry a magnetometer to take measurements and collect data.

The founders of Moon Express see the moon as just another continent, with the long-term economic potential to produce resources essential to humanity’s future on Earth and in space. Team Moon Express has already won two GLXP Milestone Prizes: the Landing Prize (US$1 million), and the Imaging Prize (US$250,000) and aims for the grand prize in 2017 with its MX-1E lunar lander, described as “about the size of a large coffee table.”

For the GLXP, Moon Express contracted Rocket Lab USA (Los Angeles, CA, US) for launch, using its Electron two-stage launch vehicle with a Rutherford liquid engine. Peter Beck, Rocket Lab founder and CEO, says, “The success of the innovative technologies we have been developing, including 3D printing, carbon composite structures and proprietary battery technology, are key factors in enabling Rocket Lab to offer frequent and affordable, dedicated launch opportunities.” Electron is a fully carbon composite vehicle, and its carbon composite fuel tanks are compatible with liquid oxygen, “the powerful cryogenic oxidizer used in Electron,” Beck says. Rocket Lab has announced completion of its private orbital launch complex, Launch Complex 1, on New Zealand’s Mahia Peninsula, which it says will be the primary site for launches of Rocket Lab’s Electron vehicle.

Synergy Moon International is a growing collaboration of individuals from more than 15 countries. Its spacecraft hardware is named Tesla, in honor of Serbian inventor, engineer and physicist Nikola Tesla (who is directly related to one of the original members of Synergy Moon), says Kevin Myrick, co-founder. The lunar lander for the GLXP, tentatively called Tesla Surveyor, consists of a spherical lander that encloses a rover to be released on the moon’s surface. The rover is a two-wheel design with a small pipe between the wheels. Solar panels (for power), cameras, a transmitter, a small computer for guidance and other mission-specific equipment will be supported on the pipe.

Myrick says materials will be selected for their ability to withstand the environment on the moon. He expects composites might be used for some parts for their weight-to-strength and temperature resistance attributes.

In the launch structure, Tesla Surveyor will sit on a frame inside a glass fiber composite payload fairing. For landing, airbags packed around the spherical shell will release and allow the shell to roll across the surface to a safe stop, based on a NASA/JPL design for its Mars rovers Spirit and Opportunity. The “petals” of the sphere will then open, releasing the rover.

Synergy Moon International contracted with Interorbital Systems (IOS, Mojave, CA, US) for launch services. Launch target is December 2017, most likely from the Pacific Ocean, off California. Randa Milliron, IOS CEO and co-founder, explains that IOS rockets are constructed by bundling its scalable Common Propulsion Modules (CPM) into larger multi-unit launch vehicles constructed to meet any mission requirement. Tesla Surveyor will be launched by IOS’s four-stage Neptune 8 LUNA, an eight-module vehicle assembled from eight CPM 2.0s.

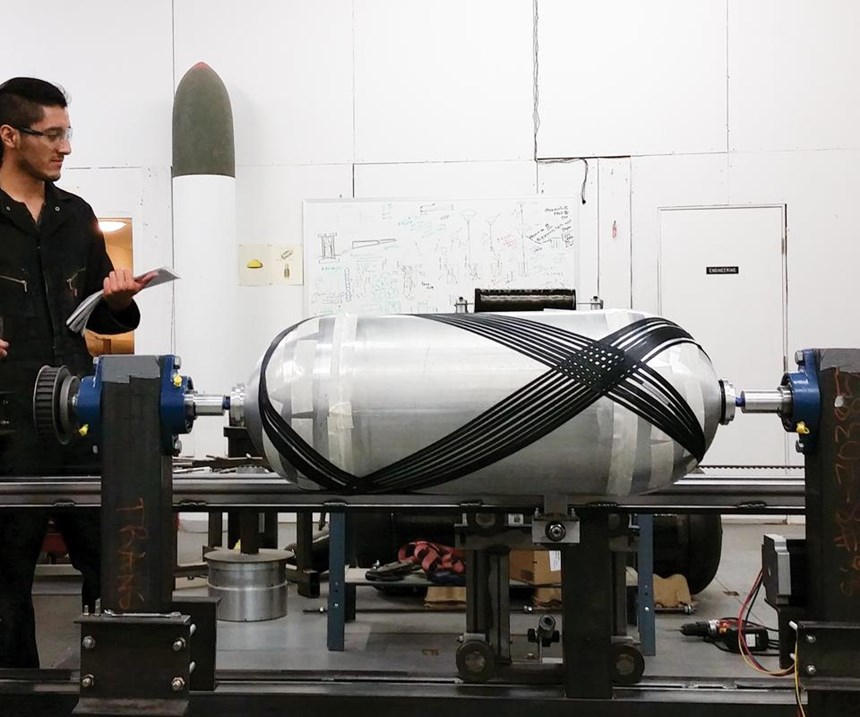

Each CPM 2.0 comprises an array of four carbon fiber lament wound tanks, a single gimballed engine, a valve and controller unit, and the fiberglass payload fairing. The CPM 2.0’s four-tank array includes three propellant tanks and a single pressurant tank to provide regulated pressurant flow during the operation of the rocket engine. Engine and tank structures and are made on IOS’s own carbon composite filament winding machine. These engines also employ an ablative composite liner that allows the engine to withstand the >2,760°C flame.

“We expect to eventually use our rockets for launch of both cargo and man-rated vehicles, for LEO orbit and to the moon,” Milliron says. “We see the moon as a new industrial site to exploit and enjoy.”

Hakuto signed Toray Composites (Tokyo, Japan) onto its team as a provider of carbon composite material and the design and manufacture of carbon fiber composite bodies, autoclave-molded, for Hakuto’s envisioned Dual Rover system: a two-wheeled Tetris and four-wheeled Moonraker. In 2014, Hakuto won a Mobility system Milestone Prize (US$500,000).

TeamIndus’ is building a 7-kg, four-wheel-drive rover, code-named ECA, to be powered by solar energy generated by photovoltaic panels on its back.

Although aluminum is the primary material used for TeamIndus’ spacecraft, carbon fiber composites will be used to reduce mass in structural elements, such as joints and connectors, says Rahul Narayan, fleet commander for Axiom Research Labs Pvt. Ltd., a TeamIndus member. Additionally, the ECA rover main chassis will include some composite elements for non-stress-bearing members.

TeamIndus’s launch contract will deliver its spacecraft/lunar lander to Earth orbit, after which the spacecraft is programmed to navigate to the moon for a soft landing in Mare Imbrium 21 days later. The prototype for this spacecraft won the US$1 million Milestone Prize for landing technology early in 2015. Notable particularly because they are competitors, TeamIndus and Hakuto have struck an unusual deal. “TeamIndus has, for a commercial consideration, contracted to carry Hakuto’s rover on board its spacecraft to the Moon,” explains Narayan. The most recent teams to receive verification of their launch contracts, Hakuto and TeamIndus, will see their robots travel together on the Polar Satellite Launch Vehicle (PSLV), developed by the Indian Space Research Organization (ISRO, Bengaluru) under the Indian Department of Space. Both rovers will then deploy from the spacecraft and proceed with each individual competitor’s specified travel and transmission mission requirements.

After the contest, TeamIndus hopes to continue use of its space-grade technology to maintain business in the space industry, and to build satellites.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More