Guide for Testing Polymer Matrix Composite Materials

Dr. Donald Adams offers insight into ASTM D 4762, a compendium of knowledge about standards relevant to testing polymer composites.

The title of this month’s column is not just designed to capture your attention, it also is the actual title of ASTM Standard Guide D 47621. This standard has been in existence since 1988, but has attracted relatively little attention since its inception 22 years ago. One contributing factor is that, until recently, it was not complete nor kept up to date. The standard was revised for the first time in 2004, 16 years after it was originally written. Many new test methods were introduced and standardized during the time interval before the first revision, and many have been introduced since. Therefore, the entire Guide was revised again, and extensively expanded in scope, in 2008. Thus, the current edition is much more up to date. Still, the Guide remains relatively unknown. This is unfortunate because the document is truly a treasure chest of information for anyone who is attempting to identify and select a specific test method, or looking for some assistance in making relative comparisons between competing test methods.

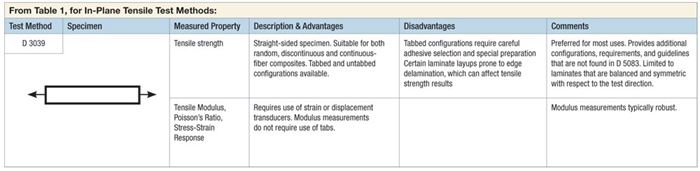

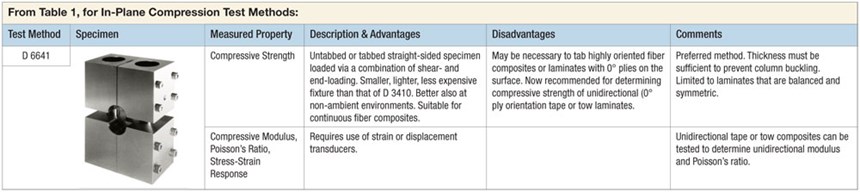

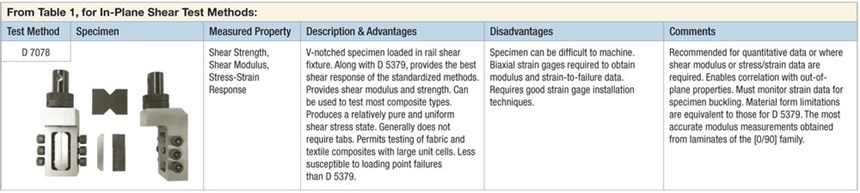

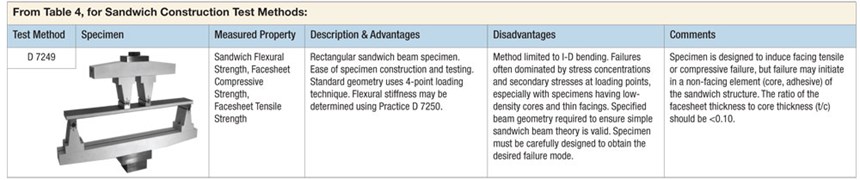

ASTM D 4762 has two main parts. The first is an extensive listing of ASTM standards relevant to the testing of polymer-matrix composites. The second part is a series of six tables that define what properties are governed by each of these standards and, most importantly, the advantages and disadvantages of each test method it defines. Explanatory comments are provided where appropriate.

The list of relevant ASTM standards is arranged numerically, and includes the title of each standard. The list is divided into two main groups — those standards governed by ASTM Subcommittee D30 on Composite Materials and those governed by Subcommittee D20 on Plastics. There is also a supplemental list of other standards of secondary interest, plus references to sources of information about definitions and symbology that are specific to composite materials, preparation of test specimens and standard data-reporting formats.

The six tables that describe the various test methods are titled as follows:

- Lamina/Laminate Static Properties

- Lamina/Laminate Dynamic Properties

- Laminate/Structural Response

- Sandwich Constructions

- Constituent/Precursor/Thermophysical Properties

- Environmental Conditioning/Resistance

Perhaps the best way of explaining the types of information available in these tables is to give a few specific examples abstracted from the Guide (see “Sample Tables for ASTM D 4762,” at right). Note that these are just four of the approximately 100 entries in the tables included in ASTM Standard Guide D 4762.

Without question, this Guide will require frequent revision in the future as additional standards are introduced, and the descriptions and appraisals will need thorough updates as existing standards are revised and new knowledge is gained. Fortunately, ASTM Committee D30 on Composites appears to be committed to this task, as evidenced by its activities during the past few years. And I am sure that the committee will welcome suggestions for further improvements in format, as well as content.

References

1ASTM D 4762-08, “Standard Guide for Testing Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, Pa.), 2008 (originally published 1988).

Related Content

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.