The increasing commercialization of space has found the industry under the environmental microscope, as its few conservation regulations could have ominous consequences if left unaddressed. Photo Credit: European Space Agency (ESA)

As with most other composite applications, the space industry uses composites where high specific strength, high glass transition temperature (Tg), high modulus (E), high thermal stability (Ts) and low water absorption are essential. Composite structures are in almost every aspect of space vehicles, including solid rocket engines and pressure vessels for fuel and gas storage, high-temperature components in rocket nozzles and sections of the core booster interstage.

Upper stage liquid fuel and gas tanks are often constructed from thin-wall metallic liners overwrapped with carbon fiber-reinforced epoxy, also known as Type IV tanks. Unlined Type V composite cryo tanks have also been successfully deployed. Composite use extends to the orbiting spacecraft, where honeycomb-cored composite sandwich panel structures support instruments and other payloads where lightweight and environmental stability are critical. Deployable payload fairings, radio frequency reflectors and solar array substrates also use composites, and carbon-carbon composite panels shield spacecraft that reach +1,260°C during atmosphere re-entry.

Environmental challenge

The rise of private rocket firms supporting satellite outfits, space station component manufacturers, interplanetary research expeditions, and personal space flights is proliferating the commercialization of space. The space industry has recently found itself under the environmental microscope, as its few conservation regulations could have ominous consequences if left unaddressed. Spacecraft construction will soon be subject to strict oversight by REACH (Registration, Evaluation, Authorization and Restriction of Chemical Substances), a European Commission-developed directive that limits the use of chemical substances hazardous to human health or the environment.

To achieve REACH compliance, spacecraft manufacturers must register all used substances with the European Chemicals Agency (ECHA). ECHA maintains a candidate list of “Substances of Very High Concern” that will face strict control or be outlawed. Substances set to be outlawed are given a definite date for their use to phase out, known as a “sunset date.” Beyond the sunset date, companies will need to apply for authorization to use a banned substance proving that the overall risk posed by stopping its use is greater than that of continuing.

Composite structures are used in almost every aspect of space vehicles, including rocket engines, pressure vessels for fuel and gas storage, high-temperature components in rocket nozzles and sections of the core booster interstage. Photo Credit: European Space Agency (ESA)

“The ‘Substances of Very High Concern’ list scrutinized by REACH might impact as much as 20% of our materials database,” Dr. Ugo Lafont, space materials and technology specialist at the European Space Agency (ESA), says. “The space industry needs to be proactively engaged as early as possible to avoid surprises and costly mitigation actions in the later stages of space projects. ESA has set out plans to manage the risk of obsolescence where certain commonly employed materials and processes are no longer available in supply lines.”

REACH could affect the space industry’s use of composite materials. For example, several substances made from petroleum products and commonly used in epoxy and vinyl ester resin formulations are in line to be banned. One such substance, Bisphenol A (BPA), is a building block constituent of epoxy resins. It is estimated that 85% of global epoxy resin production is derived from reacting epichlorohydrin (ECH) and BPA. BPA is a known endocrine disruptor that can interfere with human hormones, prolonged exposure to which can have significant health implications.

Challenges in space

Bio-based monomers have shown promise in tackling the challenges set out by sustainability legislation for many polymer applications. However, the space industry has the additional challenge of confronting the space conditions with bio-sourced materials. “In space, there is no atmosphere, so objects in space are exposed to the full spectrum of radiation from the sun,” Lafont explains. “Bio-based resin must survive and perform in the space environment and resist molecular degradation from radiation.”

“In the high vacuum of space, trapped gas or vapor molecules previously dissolved or absorbed in a solid material can be released in a phenomenon known as outgassing,” Lafont continues. “Outgassing can include sublimation and evaporation, which are phase transitions of a substance into a gas and desorption. The main consideration of outgassing is the resulting mass loss, which can impact the material’s ability to perform compromising mission success. Polymers used on spacecraft are typically manufactured from materials with very low vapor pressure to minimize mass loss caused by outgassing.”

The most challenging aspect of space is the thermal environment. Lafont notes, “Objects in orbit can be subject to large and rapid temperature swings in a matter of minutes. The material needs a glass transition temperature (Tg) appropriate for the space conditions.” The Tg is the point at which a polymer transitions from a rubbery state to a glassy state or vice versa. “As a baseline, materials under development are always screen-tested between +100°C and -100°C,” Lafont says.

Chemical solution

ESA teamed up with Professor Alice Mija of the Institute of Chemistry of Nice (ICN) at Université Côte D’Azur (Nice, France) and her team of Ph.D and post-doc researchers to develop a new breed of aromatic, 100% bio-based epoxy monomers with bio-based anhydrides to produce thermoset resins with properties competing with those made from petroleum-based sources for space composite applications.

This cooperation takes the form of a part-sponsored Ph.D. and post-doctorate research at ICN with support through ESA’s Open Space Innovation Platform, which sources promising new ideas from academia, industry and the public. The project is a three-year mission with ESA, Thales Alenia Space (Cannes, France) and Université Côte D'Azur. At the time of this article, the team was 16 months into the project.

“The capabilities of monomers are based on principal chemistries,” Professor Mija explains. “We are working on bio-based molecules which can compete with the bisphenol A, featuring two or more aromatic groups, giving rigidity and physical properties — strength and thermomechanical performance — [which are] critical elements of the epoxy resin.”

“Our research is focusing on nontoxic aromatics that behave as the existing commercial, petroleum-based and toxic resins; mainly molecules that can be used in cosmetics, pharmaceuticals, etc.,” Professor Mija continues. “We found several natural, renewable and eco-friendly synthons and characterized them to determine whether they would have the desired performance if we synthesized the monomers, carried out polymerization and created a thermoset resin from them.”

Test pieces made from 100% bio-based composite material, tested and deemed suitable for space applications. Photo Credit: Université Côte d’Azur

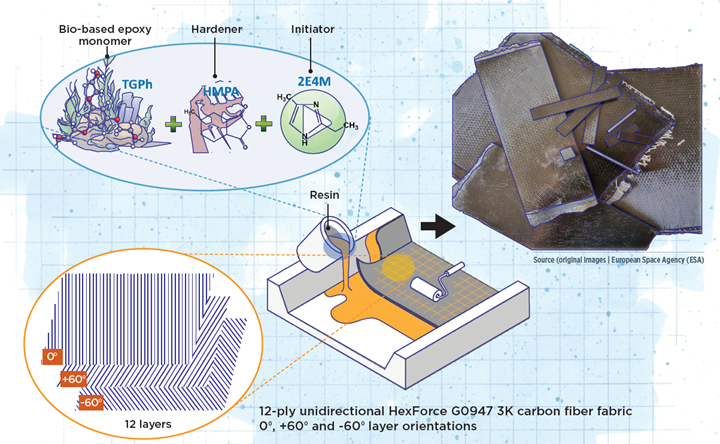

Professor Mija’s team synthesized several bio-based monomers containing a tunable content on aromatic rings per molecule and two or more polymerizable functionalities. One of the most performant is the triglycidyl ether of phloroglucinol (TGPh), a bio-based aromatic monomer obtained from phloroglucinol extracted from algae. It is abundant in nature, local to Europe and many other regions of the world — suiting the sustainability outlook — and is not prohibitively expensive. It is also completely renewable as it doesn’t require cutting down trees or planting specific crops to obtain it.

Copolymerization of TGPh can be carried out between 35 and 70°C, enabling industrial scale-up using the current processes for resin production. The monomer was cross-linked with hexahydro-4-methylphthalic anhydride (HMPA), an anhydride produced from biomass at a laboratory scale. The reaction was initiated by 2-ethyl-4-methylimidazole (2E4M) to form a thermoset resin in the same way that petroleum-based epoxy is created, maintaining current equipment, infrastructure, etc.

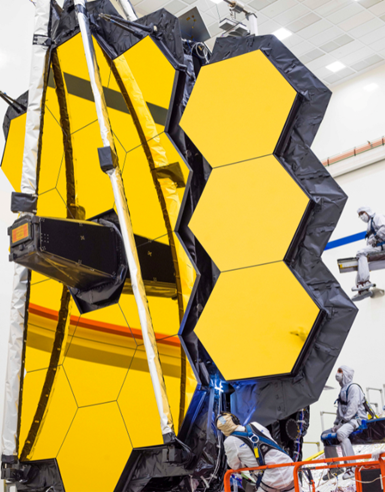

Outgassed molecules in space tend to be attracted to smooth objects and surfaces, like a camera mirror, which can result in a change in light absorption or reflection of the camera. Above is the James Webb telescope’s primary mirror — a sensitive surface susceptible to outgassed material. Photo Credit: European Space Agency (ESA)

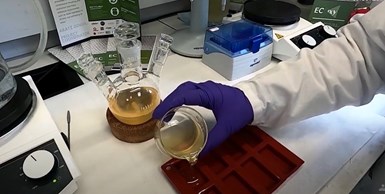

The physicochemical and thermomechanical properties of the 100% bio-based resin were investigated by a variety of techniques, including thermogravimetric analysis (TGA), dynamic mechanical analysis (DMA), tensile and compressive testing, shore tests, water absorption, swelling ratio and gel content testing. In view of the high-end space application, obtaining a bio-based thermoset resin with good mechanical performance and a Tg above 100°C was a key target.

The produced thermoset measured a Tg of 210°C, a modulus of 3.1 GPa at 30°C, thermal stability range up to 359°C and a 1.5% water absorption average after 15 days. What’s more, the thermal degradation values for the material are superior to those reported for petroleum-based epoxies. Mija’s team concluded that the copolymerization of TGPh cross-linked with HMPA and 2E4M initiator successfully achieved the 100% bio-based recyclable, reprocessable and repairable (3R) thermoset resin from renewable resources target with appropriate physicochemical and thermomechanical performance for space applications.

Validating bio-based resin

A 12-ply unidirectional (UD) Hexcel (Stamford, Conn., U.S.) HexForce G0947 3K carbon fiber fabric with 0°, +60° and -60° layer orientations, was created to test the 100% bio-based thermoset resin as part of a composite structure. The construction of the test piece does not represent any particular spacecraft part; it was strictly created for testing purposes.

The manufactured test piece validated that the bio-based resin caused no change to the production processes to make a composite material. Tensile testing was carried out to validate the working performance of the consolidated part and thermomechanical testing — cooling and heating the test piece from -100°C to +100°C and back for 100 cycles — measured any induced thermal fatigue that may lead to delamination that otherwise would not occur if the composite was used on Earth. The tests confirmed the material achieves the required stability and coefficient of thermal expansion (CTE) for space applications.

The development of 100% bio-based thermoset resins for space composites was driven through ESA’s Open Space Innovation Platform, in collaboration with the Nice Institute of Chemistry (ICN) – Université Côte D’Azur, sourcing promising new ideas for research from academia, industry and the public domain. Photo Credit: European Space Agency (ESA)

ESA carried out outgassing compliance screening following the European Cooperation of Space Standardization ECSS-Q-ST-70-02C standard. This standard describes a thermal vacuum test to determine the outgassing properties of materials proposed for the fabrication of spacecraft and associated equipment, external hardware of inhabited space systems, space flight hardware and certain launcher hardware. The test accurately measures the mass of the material before and after being subjected to a high vacuum and 125°C.

The outgassing compliance screening is performed in a chamber where the concentration, introduction, generation and retention of desired airborne particles can be accurately controlled. It must also ensure that temperature, humidity and pressure parameters can also be accurately controlled as required.

During the screening, collected volatile condensable material (CVCM) — the quantity of outgassed matter from a test specimen that condenses on a collector maintained at a specific temperature for a particular time — is measured. CVCM is expressed as a percentage of the initial specimen mass and is calculated from the condensate mass, which is determined from the difference in mass of the collector plate before and after the test.

The ECSS-Q-ST-70-02C standard requires a total mass loss (TML) of the specimen without absorbed water — known as recovered mass loss (RML) — of less than 1%. CVCM must be below 0.1%. The TML is primarily applicable if the mission will see cryogenic conditions.

One-hundred percent bio-based thermosetting resin fit for space being tested at the Nice Institute of Chemistry at the Université Côte D'Azur. Photo Credit: Université Côte D'Azur

The space-qualification tests are currently ongoing at ESA’s ESTEC technical center (Noordwijk, Netherlands) as well as Thales Alenia Space, a near neighbor of ICN – Université Côte D'Azur. At the time of this article, the thermomechanical cyclic compliance testing was still being carried out. However, outgassing test results shows compliance and performance results of the 100% bio-based thermoset resin are well above the requirements to be certified for use in space composites.

Future composite evaluations

In the future, ESA and Université Côte d’Azur Institut of Chemistry of Nice plan to investigate the use of natural fibers as an alternative to carbon fibers to complete the 100% bio-based composite construction. “It is still the case that the properties of carbon fiber result in the most desirable properties for space composites,” Lafont admits. “However, natural fibers should be absolutely suitable for some specific space applications.”

“One of the main limitations regarding the properties of natural fibers is their hygroscopic tendencies,” he continues. “This would mean the fibers would have to be processed to get rid of all the water inside and ensure that it is not reabsorbed in any part of the production process. A methodology that has been considered is coating the fibers or the composite structure so that no water can be released from the part if there is any inside. This is a significant consideration for space applications because should any water be released from the structure while the component is in space, it will create ice which can cause all sorts of challenges.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More