ESI Group

Batiment Le Seville

3 bis Rue Saarinen, CS 50468

Rungis, 94528 FR

33 (0)1 41 73 58 00

mathilde.chabin@esi-group.com

esi-group.com/products/composites

About ESI Group

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

ESI Group Supplies the Following Products

- CAD/CAM/CAE design

- CAD/CAM/CAE hardware/software

- Civil engineering

- Consulting, health and safety

- Consulting, other

- Consulting, process development

- Education/Training

- Product design

Editorial, News, and Products

-

Aernnova Composites, leader in composites R&D

This sidebar to CW’s July 2024 feature article reviews the company’s achievements and capabilities through years of composites R&D programs.

-

CAELESTIS R&D project explores predictive design, manufacturing for aerospace

Over 42 months, 11 partners will work together to develop an end-to-end digital thread to effectively enable dataflow across the entire aircraft value chain, accelerating the optimization of disruptive aircraft and engine configurations.

-

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

-

One-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

-

IMDEA Materials Institute helps create intelligent sensors for aviation composites

As a part of the European Union’s DOMMINIO project, IMDEA Materials Institute is helping to create embedded smart sensors via 3D printing to provide real-time updates on aircraft during flight.

-

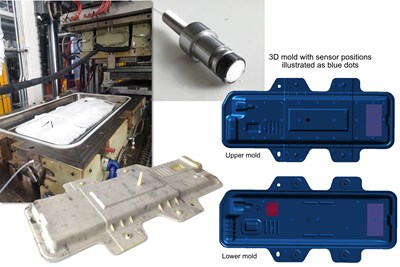

Customizing ultrasonic sensors for composites process optimization and control

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

-

CosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

-

Developing next-gen, smart engine composite fan blades

EU-funded MORPHO project will use embedded sensors, data-driven hybrid twins and machine learning to increase RTM yield, improve damage-tolerant design, achieve SHM and 100% recycling.

-

Advancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

-

Carbon fiber automotive parts production industrialized via C-RTM process

Compression resin transfer molding overcame the difficulty in shaping CFRP car parts with development time reduced by 50%.

-

Revolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

-

Highlights: Composites Convention 2019

Highlights from the Composites Convention 2019, June 12-13, in Stade, Germany, organized by CFK Valley e.V. and Carbon Composites e.V, and the German Aerospace Center’s 5th Colloquium on Production Technology, on May 15, in Augsburg.

-

Proving performance in EV powertrains

Simulation-driven development replaces aluminum with thermoplastic composites in gearbox housing.

-

Advancing composites through virtual and augmented reality

A review of technologies that are bridging the technical divide between the virtual world of design and simulation, and the real-world of composites manufacturing and repair.

-

Fast and Faster: Rapid-cure resins drive down cycle times

New systems include sub-1-minute cures ideal for higher automotive production volumes.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Resin transfer molding: An update

Fulfilling the promise of OOA composites without sacrificing pressure.

-

Understanding the influence of fiber orientation on structural analysis of fiber-filled parts

The effect of fiber orientation on material properties is a key way the injection molding process impacts mechanical performance. Doug Kenik and Angie Schrader of the Design, Lifecycle & Simulation product group at Autodesk (Waltham, MA, US) illustrates two ways fiber orientation influences the structural behavior of fiber-filled parts and discuss the need for a bi-directional approach to design and analysis.

-

Software Update: Simulation saves

A look inside the increasingly well-equipped virtual toolbox for composite design, analysis, and manufacturing.

-

Cutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

-

SPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

-

Integrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.

-

High-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

-

JEC COMPOSITES 2008 show review

Composites professionals converged on this annual Parisian gathering in greater numbers than ever before, confident that the market’s global growth will continue.

-

FEA Roundup: Design, Simulation And Analysis Converge

New modeling and analysis software products increase the accessibility and reliability of finite element analysis data.

-

Liquid Composite Molding Achieves Aerospace Quality

Improvements in materials, tooling and process control bring RTM and VARTM into the realm of aerospace components.