Hybrid thermoplastic molding: Toughening automotive composites

Tailored D-LFT with continuous and discontinuous glass offers best combination of strength, moldability.

As interest in composites has increased in ground transportation, significant work has been underway among resin and reinforcement suppliers, processors and machinery makers to find better ways to meet the needs of automotive OEMs and their suppliers. One standout effort by a consortium of European and North American organizations, reported in 2012 (a Society of Plastics Engineers Automotive Composites Conference and Exhibition Best Paper winner), evaluated methods to increase impact strength without sacrificing moldability of compression-molded thermoplastic composites.

A model of collaboration

In 2011 thermoplastic-resin supplier Ticona Engineering Polymers (Florence, Ky., and Sulzbach, Germany) approached research hub Fraunhofer Institute for Chemical Technology (Fraunhofer ICT, Pfinztal, Germany) about conducting a study on thermoplastic composites. Michael Ruby, Ticona’s global composites business manager, explains: "To support the automotive sector, we felt it was important to show technology leadership in application development, so we took on the topic of localized reinforcement of structural automotive composites. Our aim was to utilize demonstrator projects to create the technical knowhow that would become the basis for commercial applications."

Ticona provided its Celstran CFR-TP PP-GF70 unidirectional (UD) glass/polypropylene (PP) tapes (70 wt-% glass, 0.25-mm/0.01-inch thick) slit to various widths. Some of the tapes were converted by Oxeon AB (Borås, Sweden) into its trademarked TeXtreme plain-weave fabrics (unconsolidated, 0.50-mm/0.02-inch thick per layer, in 0°/90° and ±45° configurations). The balance of the tapes were formed by Fiberforge (Glenwood Springs, Colo.) into its Tailored Blank laminates—preconsolidated 0°/90° sheets in four thicknesses and a quasi-isotropic layup (0°/90°/+45/-45s, where s represents number of layers of laminate symmetry) — using the company's patented RELAY tape laying process.

At this point, a research team comprising members from each company, led by Ticona composites application development engineer Daniel Grauer and Fraunhofer R&D engineer Benjamin Hangs, assembled at the Fraunhofer ICT campus for several days of testing. During test sample molding, Fraunhofer inline compounded a third material, a discontinuous-glass, direct long-fiber thermoplastic (D-LFT) with a PP matrix. (Fraunhofer ICT codeveloped the D-LFT process with Dieffenbacher GmbH Maschinen- und Anlagenbau, Eppingen, Germany, in the late 1990s and early 2000s. By the mid-2000s they had codeveloped the process hybrid that was used in this study, which they call tailored D-LFT. Today the process is primarily used by select automotive composites molders in Europe. See "Evolution of tailored D-LFT, " at the ehdn of this article or click on its title under "Editor's Picks," at top right).

The D-LFT combined PP-C711-70 RNA resin supplied by Dow Chemical (Midland, Mich.); an additives package that featured a Priex 20078 coupling agent to improve impact strength and AddVance 453 stabilizer supplied by Addcomp Holland BV (Nijverdal, The Netherlands); and JM 490 glass fiber (2400 tex) supplied by Johns Manville (Denver, Colo.),initially used at 30 wt-%, the most common automotive loading.

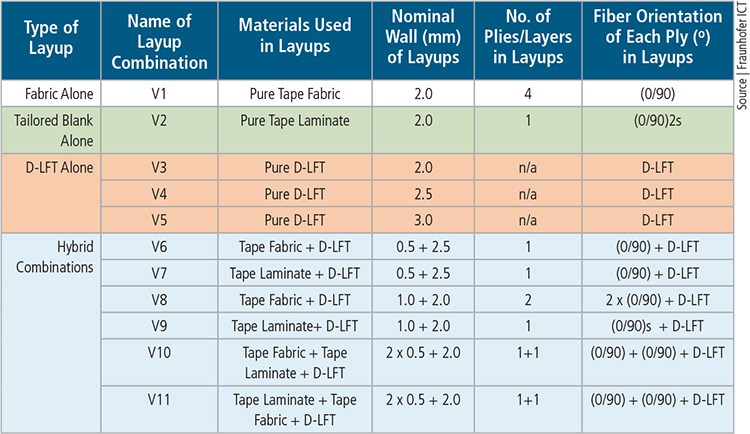

The team layed up the three material types — alone and in various combinations — in a compression molding press in several thicknesses to produce 400-mm/15.75-inch square flat test plaques. Next, samples were waterjet cut and subjected to the EN ISO 6603-2 “Determination of Multiaxial Impact Behavior of Rigid Plastics – Part 2: Instrumented Puncture Test.”

Based on results seen in the small test plaques, the researchers embarked on the study's next phase and devised a new layup that combined the three materials. They used it to mold parts in a 1,100-mm by 800-mm (43-inch by 32-inch) tool previously used for commercial (series) production of an engine noise shield (loaned to the institute by Minda Schenk Plastic Solutions, Esslingen, Germany). Because the back (vehicle-facing) side of the part had tall, thin ribs, which are impossible to fill with unidirectional glass, D-LFT alone was used on that side.

On the front (road-facing) side, which was subject to stone impingement from tires, the team wanted to see if impact strength and toughness could be improved, so that side featured the tape-based fabric and laminate. The team evaluated the time it took to heat fabrics and laminates, compound the D-LFT, stack materials in the tool and form parts to determine if the hybrid material and molding process was fast enough for commercial automotive use. Because the shield tool lacked fixtures to hold the tape-based fabrics and laminates in place, researchers were concerned that the materials might shift out of position during molding. Each product was distinctly colored (fabrics were black, laminates were yellow, and D-LFT was blue) so the team could see where they ended up in the final part.

Balancing impact vs. moldability

Although the composites industry has long recognized the benefits of using continuous-strand reinforcements to boost the stiffness, strength and toughness of materials, UD tapes — as produced — are not always easy to use directly in compression molding or other thermoplastic forming processes because they can move in the tool during molding. When tapes are converted into fabrics or laminates, larger and thicker plies can be formed, and these are less likely to shift during molding. In the case of Tailored Blanks, they also can be precut to net or near-net shape, which reduces postmold trimming. Additionally, the conversion process allows designers to orient tapes (e.g., 0o/90o/+45o/-45o) within the final fabric/laminate stack to improve multiaxial mechanical properties.

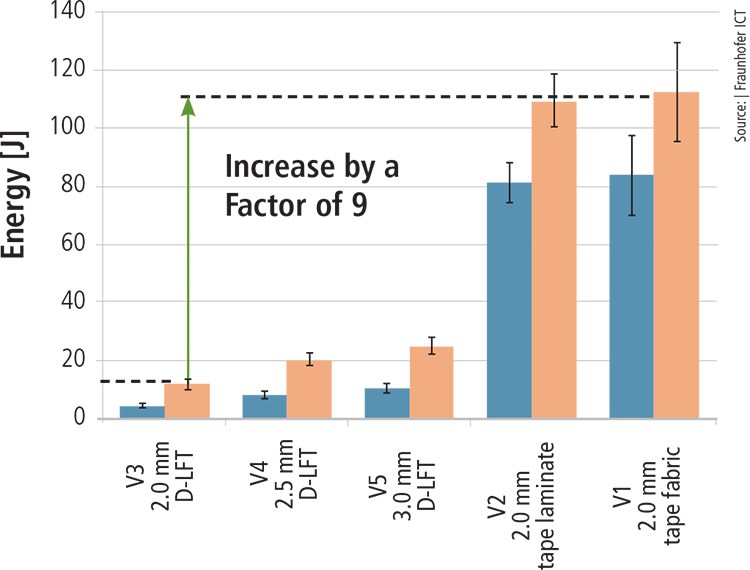

Given this, it wasn’t a surprise that the study's test plaque molding results showed that when the three material types were used solo, the fabrics and laminates offered nine times the impact strength and toughness of the D-LFT. Despite a small uptick in weight per unit area, the continuous-glass products were clearly much tougher — also no surprise because the tapes had 70 wt-% glass loading vs. 30 wt-% for D-LFT in the plaques and a mere 20 wt-% in the shield (to enhance moldability). Notably, there was almost no difference (in terms of energy at maximum force and total energy) between the tape-based fabrics and Tailored Blanks at the same thickness. Presumably, either form could be selected for a given application, based on the molder’s comfort level, material availability and geometry of the part.

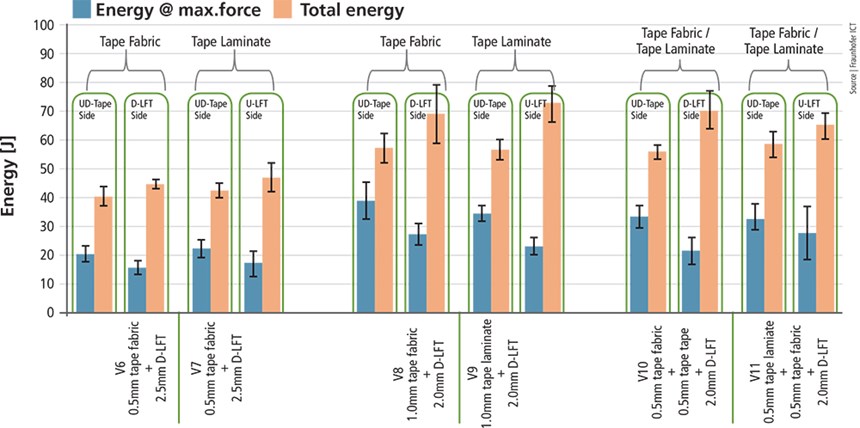

Because these hybrid plaque layups were D-LFT on one side and either TeXtreme fabric or a Tailored Blank laminate on the other side, the team wanted to get some idea of how a hybrid layup would behave in a puncture test. Researchers impacted specimens on the D-LFT side and on the tape fabric/laminate side. All samples were destroyed during testing.

When the test results from each side of each hybrid layup were compared at several thicknesses, things got interesting. Energy at maximum force was always lower when the D-LFT side of a sample was impacted, because the total energy absorbed was always higher. "We believe that because the fabric/laminate side of each sample was stiffer and stronger, more energy was needed to damage that side of the sample, hence the higher energy at maximum force measured,” Hangs explains. “Since the D-LFT side was not as stiff, it broke more easily and sooner during each test, so it absorbed less initial energy and had lower energy at maximum force. Similarly, as the impactor started breaking the D-LFT side, it put the continuous-fiber tapes and laminates into tension on the reverse side, so those samples had higher total energy. When the D-LFT failed and allowed the impactor to start puncturing the fabric/laminate side, there was less kinetic energy left in the impactor to do more damage."

What's the takeaway? "Clearly, the UD tape-based fabrics and laminates were tougher and should increase the use-life of parts that see punishing impacts like an automotive underbody shield,” Grauer contends. “Their higher cost would be offset by the fact that you'd need less of them to make a part perform better, leading to opportunities to reduce thickness at comparable performance or increase performance at slightly higher mass and sectional area.”

Hangs adds, "There are always tradeoffs in the materials world, and with UD reinforcement, what you sacrifice is moldability — at least in terms of complex geometry such as ribs, bosses and tight radii, as it's simply not possible at typical molding conditions to push continuous fibers into tight spaces."

As this study demonstrates, a hybrid materials and molding process can provide a means to deal more effectively with part complexity. Although the total energy absorbed wasn't as high as that seen with the fabric and laminate plaques (110J), the hybrid samples, which ranged from 40J to 72J, performed much better than the samples with D-LFT only (~15J).

The second part of the study was a good example of how hybrid materials and process combinations can offer the best of both worlds: increase mechanical performance where it's needed (continuous-glass fabrics/laminates on the shield's road-facing side) while maintaining moldability for challenging geometries (discontinuous-glass D-LFT on the vehicle-facing side). The process also gives molders more freedom to make changes on the fly.

Significantly, the hybrid layup also promises a cycle time that’s acceptable in the auto industry. The team managed to chart an effective cycle time of 70 seconds, which is very respectable for thermoplastics in a part this size and significantly faster than compression-molded thermosets. Sheet-molding compound (SMC), for example, posts a 2- to 2.5-minute cycle time. It’s all the more remarkable because it was achieved despite what Hangs describes as an "unoptimized" process sequence. Fabrics and laminates were preheated in an infrared oven, and materials were moved manually to the tool and then hand layed with the D-LFT. In fact, the in-tool dwell time was only 30 seconds. With options such as clamps and fixtures in the tool to hold the fabrics/laminates, an indexing infrared oven and robotic materials handling, researchers believe they could shave more time off the process.

With research results like these, study participants hope there will be more interest in exploring opportunities that hybrid material and process combinations, such as tailored D-LFT with UD tapes, can bring to thermoplastic composites in automotive and other markets.

To read more about this project, follow these links:

http://speautomotive.com/SPEA_CD/SPEA2012/pdf/TP/TP4.pdf

http://speautomotive.com/SPEA_CD/SPEA2012/pdf/about/Best%20Paper%20Awards.pdf

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)